Low-VOC (volatile organic compound) non-cleaning flux comprising complex surfactant and method for preparing same

A surfactant and flux technology, used in welding equipment, welding media, manufacturing tools, etc., can solve hidden dangers, safety, environmental pollution and other problems of no-clean flux, and achieve reduced surface tension, low solid content, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

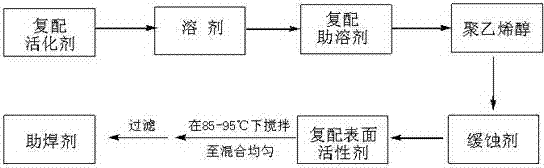

[0030] Add 0.5% succinic acid and 0.5% dl-malic acid, 1% isopropanol, 1% ethylene glycol, 1% ethylene glycol butyl ether, 0.5% polyvinyl alcohol, and 0.01% corrosion inhibitor to the reaction vessel in sequence , LA300SB 0.05% and CO-977 0.05%, the balance of self-distilled deionized water; after adding each component, stir at 85°C-95°C until completely dissolved, and filter the mixture to obtain flux after mixing evenly.

Embodiment 2

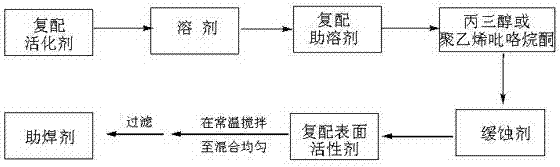

[0032] Add 1.25% of glutaric acid and 1.25% of dl-malic acid, 1% of isopropanol, 1% of ethylene glycol and 1% of butyl glycol ether, 0.1% of polyvinylpyrrolidone, and 0.03% of corrosion inhibitor in the reaction vessel , CO-436 0.25% and CO-630 0.25%, and the balance of self-distilled deionized water; after adding each component, stir at room temperature until completely dissolved, and filter the mixture to obtain flux after mixing evenly.

Embodiment 3

[0034] Add 0.6% of itaconic acid and 0.6% of dl-malic acid, 1% of isopropanol, 1% of ethylene glycol, 1% of butyl glycol ether, 1% of glycerol, and 0.04% of corrosion inhibitor in the reaction vessel , FT900 0.25% and LA300SB 0.25%, the balance of self-distilled deionized water; after adding each component, stir at room temperature until completely dissolved, and filter the mixture to obtain flux after mixing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com