Angle sensor device for bar bending machine

An angle sensor and bending machine technology, applied in the field of machinery, can solve problems such as not reaching the level of automation or semi-automation, affecting the production efficiency of steel bar bending machines, and the bending angle of steel bars is not accurate enough, so as to achieve a wide range of applications, Strength reinforcement, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

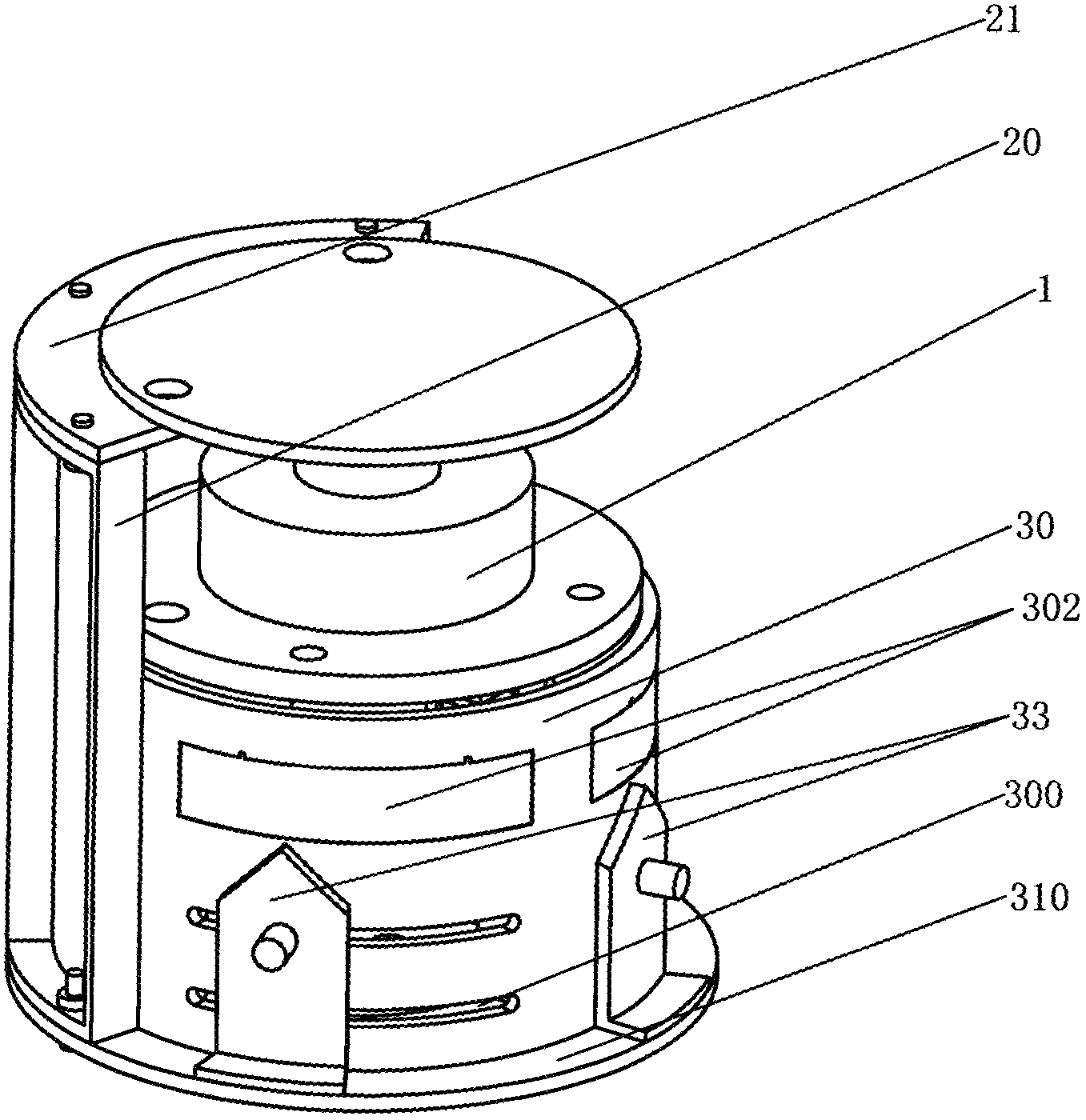

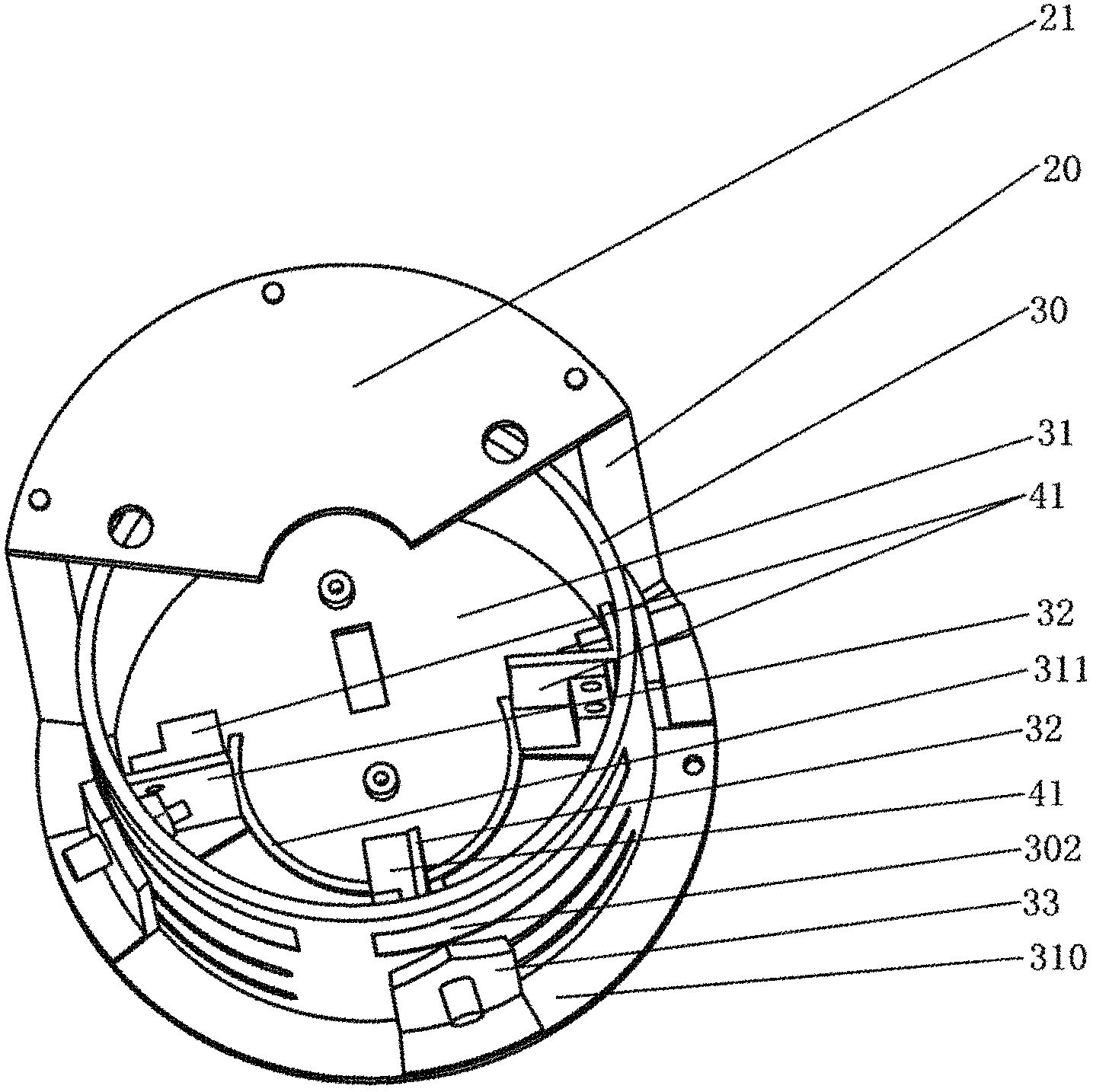

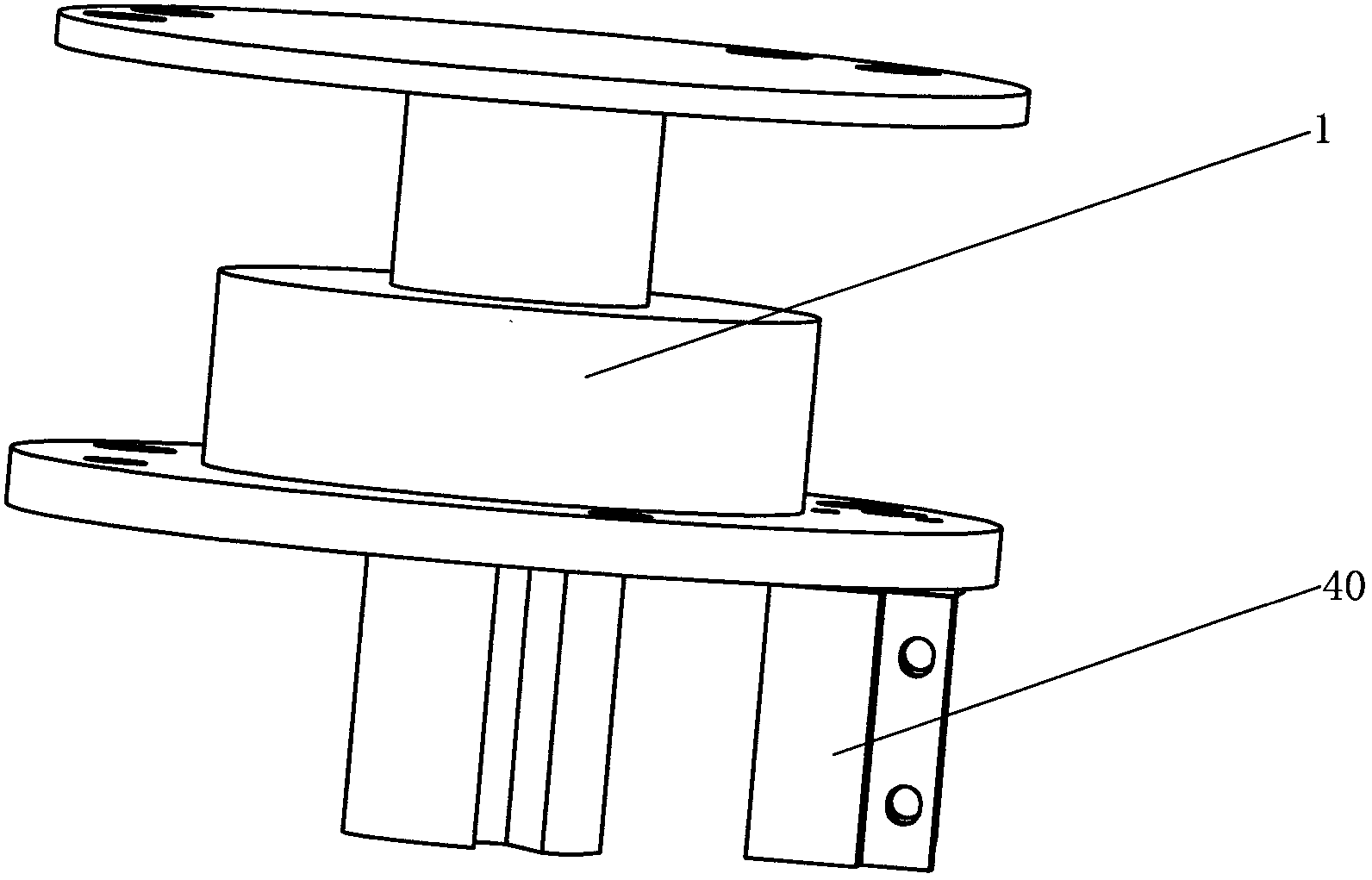

[0022] Such as Figure 1-6 As shown, the specific embodiment of the present invention is an angle sensor device of a steel bar bending machine, figure 1 Among them, the device body is installed on the main body 1 of the steel bar bending machine, combined with figure 2 and image 3 It can be seen that the angle sensing device of this embodiment includes sensing components, an arc-shaped support frame 2 installed on the body of the bending machine, and a cylindrical main body bracket 3 fixedly installed on the arc-shaped support frame 2. The sensing components include an upper sensing part 40 arranged on the main body 1 and three lower sensing parts 41 arranged on the cylindrical main body support 3. In this embodiment, the cylindrical main body support 3 is connected with the main body 1. By using the arc-shaped support frame 2 as the installation reference to form a coaxial installation, and the rotation angle of the main body 1 of the steel bar bending machine is realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com