Efficient energy-saving combined type battery pole piece two-side coater

A technology of double-sided coating machine and battery pole piece, which is applied to devices and coatings for coating liquid on the surface. The effect of running speed and land cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

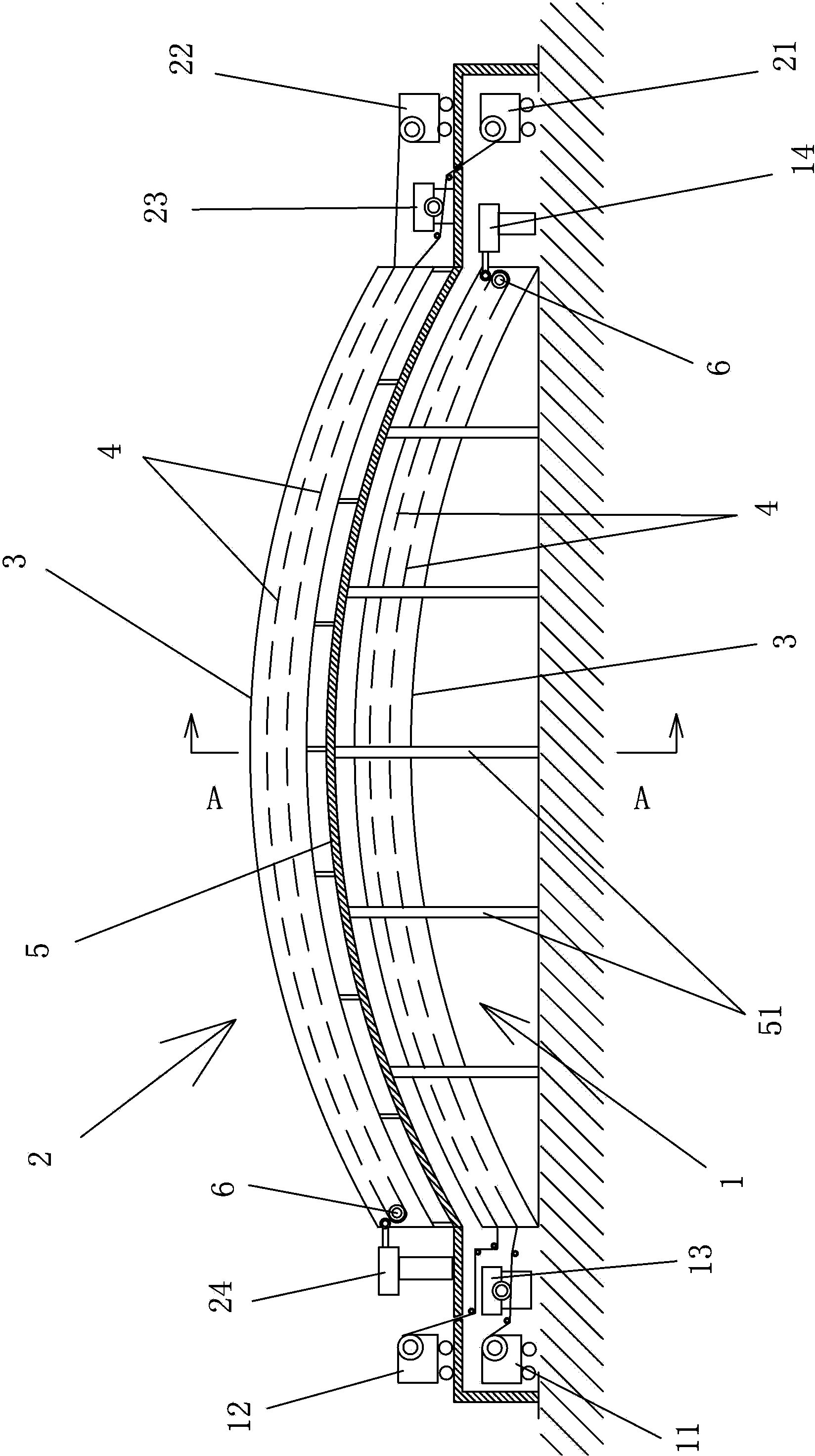

[0021] The following structural drawings and embodiments will further describe the present invention in detail.

[0022] The reference signs in the manual are as follows:

[0023] Lower coater 1, first uncoiler 11, first winder 12, first forward coating head 13, first reverse coating head, upper coater 2, second uncoiler 21, second Winder 22, second forward coating head 23, second reverse coating head 24, heating and drying device 3, battery pole piece 4, working platform 5, angle steel bracket 51, guide roller 6, circulating hot air The current equalizing oven 7 of the device, the upper drying passage 71, the lower drying passage 72, the hot air duct 73, the heater 74, the blower 75, and the return air duct 76.

[0024] The high-efficiency and energy-saving combined battery pole piece double-sided coating machine of the present invention is to set up the double-sided coating machine in the prior art according to the way of stacking up and down, and its purpose is to make ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com