Method for preparing selective catalytic reduction SCR flue gas denitration catalyst and method for preparing raw material titanium-tungsten powder of SCR flue gas denitration catalyst

A technology of denitrification catalyst and titanium tungsten powder, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problem of high material consumption/energy consumption, low benefit, and cost Advanced problems, to achieve the effect of alleviating high prices, solving environmental problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

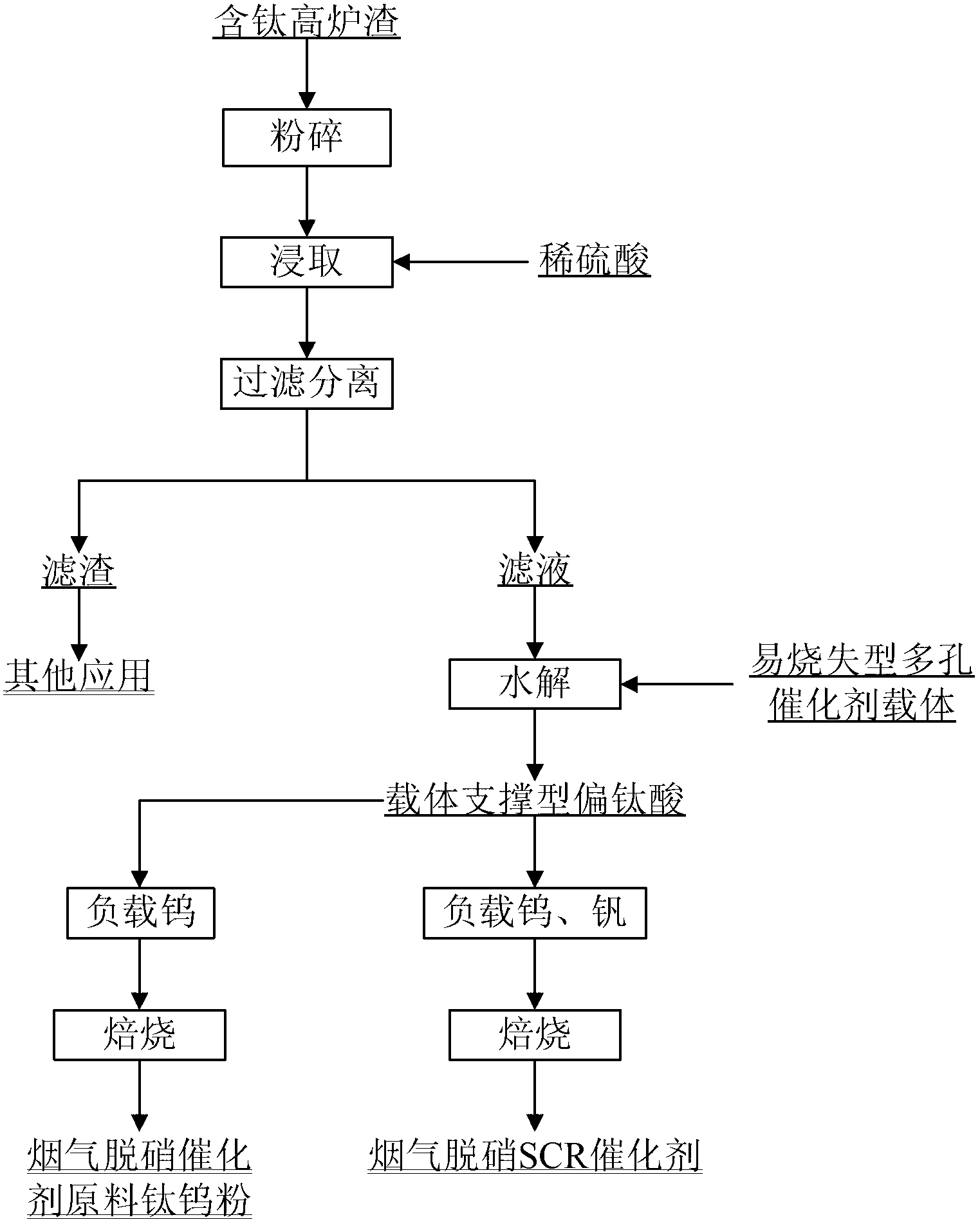

Method used

Image

Examples

Embodiment 1

[0070] Weigh 20g of titanium-containing blast furnace slag crushed to below 200 mesh, add 20% dilute sulfuric acid according to the mass of sulfuric acid (calculated as 100% sulfuric acid) : mass of blast furnace slag, and add blast furnace slag under constant stirring at 80°C. Thoroughly stir and leaching for 8 hours, after which centrifugation is carried out, the filter residue is washed 3 times with 10% dilute sulfuric acid, and the filtrate is collected for hydrolysis. Add activated carbon to the titanium solution (the amount added is TiO in titanium-containing blast furnace slag 2 20% of the mass, that is, 0.64g), add urea to adjust the pH of the titanium solution to 0.5, add ammonium metatungstate (according to WO 3 5% load), maintained at 40°C for 4h, and then raised to 105°C for 4h. After the reaction is completed, filter, and the filter residue is washed several times with dilute sulfuric acid, then washed with deionized water until neutral, dried, and then heated to...

Embodiment 2

[0072] Weigh 20g of titanium-containing blast furnace slag crushed to below 200 mesh, add 20% dilute sulfuric acid according to the mass of sulfuric acid (calculated as 100% sulfuric acid) : mass of blast furnace slag, and add blast furnace slag under constant stirring at 80°C. Thoroughly stirred and leached for 8 hours, and centrifuged after the end, the filter residue was washed 3 times with 10% dilute sulfuric acid, and the filtrate was collected for hydrolysis. Add activated carbon to the titanium solution (the amount added is TiO in titanium-containing blast furnace slag 2 50% of the mass, that is, 1.6g), add urea to adjust the pH of the titanium solution to 0.5, maintain it at 40°C for 2h, and then raise the temperature to 110°C for 8h. After the reaction is completed, filter, and the filter residue is washed several times with dilute sulfuric acid and then washed to neutrality with deionized water, and dried to obtain carrier-supported metatitanic acid, in which TiO 2 ...

Embodiment 3

[0074] Weigh 20g of titanium-containing blast furnace slag crushed to below 200 mesh, add 20% dilute sulfuric acid according to the mass of sulfuric acid (calculated as 100% sulfuric acid) : mass of blast furnace slag, and add blast furnace slag under constant stirring at 80°C. Thoroughly stir and leaching for 8 hours, after which centrifugation is carried out, the filter residue is washed 3 times with 10% dilute sulfuric acid, and the filtrate is collected for hydrolysis. Add activated carbon to the titanium solution (the amount added is TiO in titanium-containing blast furnace slag 2 20% of the mass, that is, 0.64g), add urea to adjust the pH of the titanium solution to 1.0, add ammonium metatungstate (according to WO 3 5% load), maintained at 40°C for 4h, and then raised to 105°C for 8h. After the reaction is completed, filter, and the filter residue is washed with dilute sulfuric acid for several times, then washed with deionized water until neutral, and dried to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com