Sectional absorption ammonia desulfurization process and device

A desulfurization device and desulfurization process technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of simple process, long-term operation, and land saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

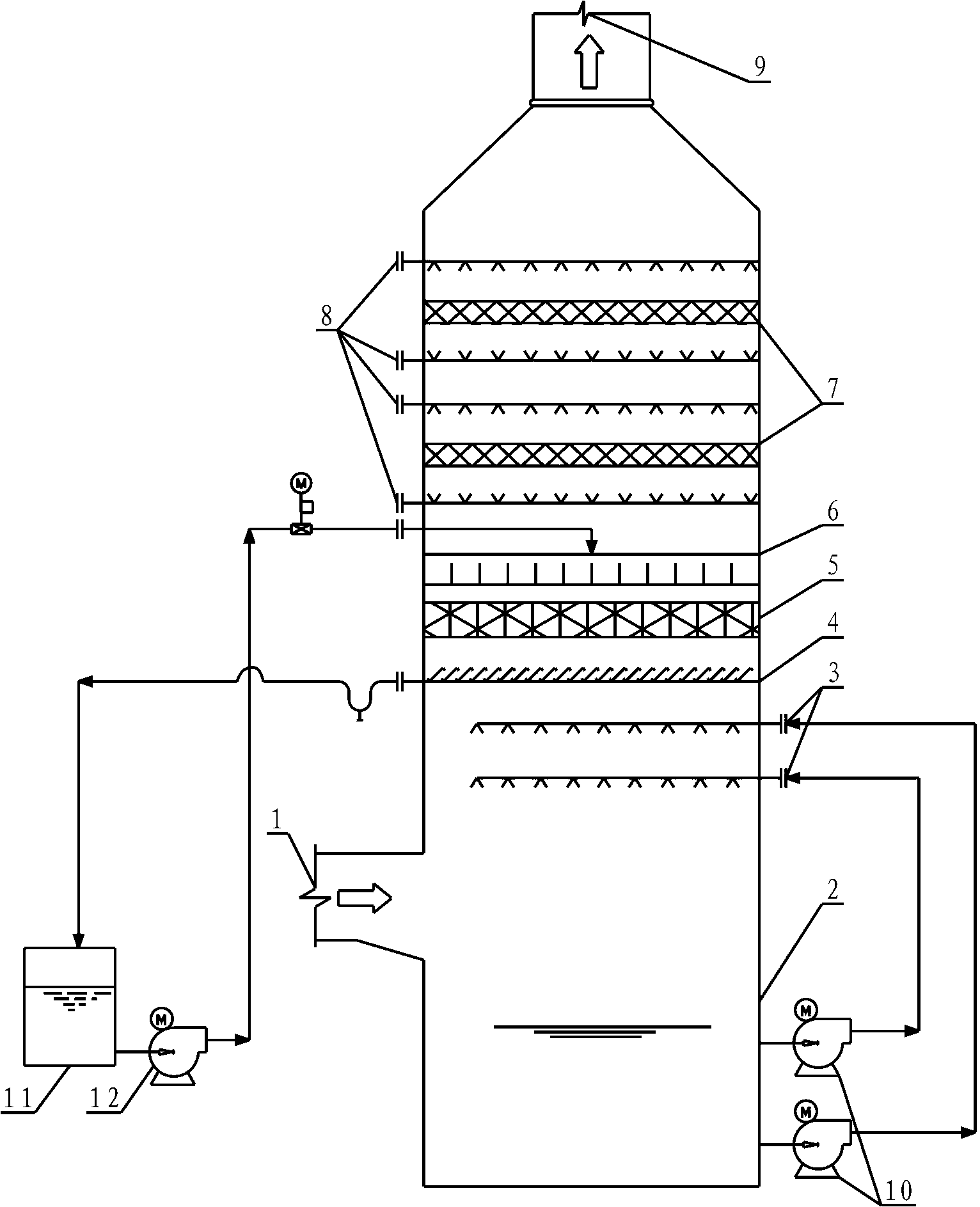

[0024] A stepwise absorption ammonia desulfurization device implemented according to the present invention includes an absorption tower 2, which is characterized in that: above the middle of the absorption tower 2, a spray layer 3, a packing layer 5, and a mist removal washing layer are arranged in the tower from bottom to top. The spray layer 3 is provided with one or several layers according to the level of sulfur dioxide content in the flue gas, and each spray layer 3 is provided with a spray slurry circulating pump 10 outside the tower; packing layer 5 and spray layer An inclined plate collector 4 (liquid collector) is set between 3, a trough distributor 6 (liquid distributor) is set between the packing layer 5 and the defogging flushing layer, and the liquid distributor is connected to the packing spray pump 12 outside the tower , The liquid collector is connected to the packing spray box 11, and the packing spray box 11 is connected to the packing spray pump 12; the demist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com