Method for removing organic matter and carbon dioxide from exhaust gas in the process of producing carbonate with carbon dioxide and fatty alcohol

A technology of carbon dioxide and carbonate, applied in the direction of carbon dioxide or inorganic carbonate preparation, etc., can solve problems such as clogging pipes and hindering ammonia condensation, and achieve the effects of small device investment, significant benefits, and simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

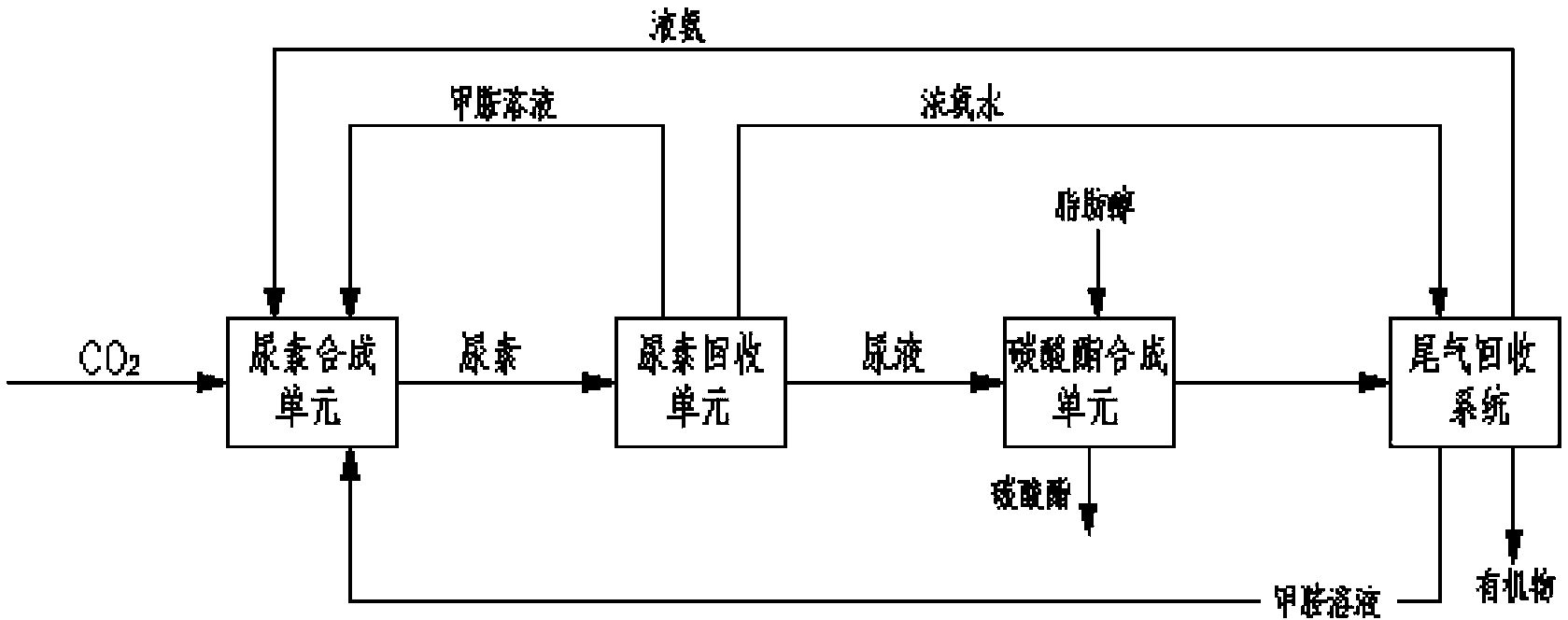

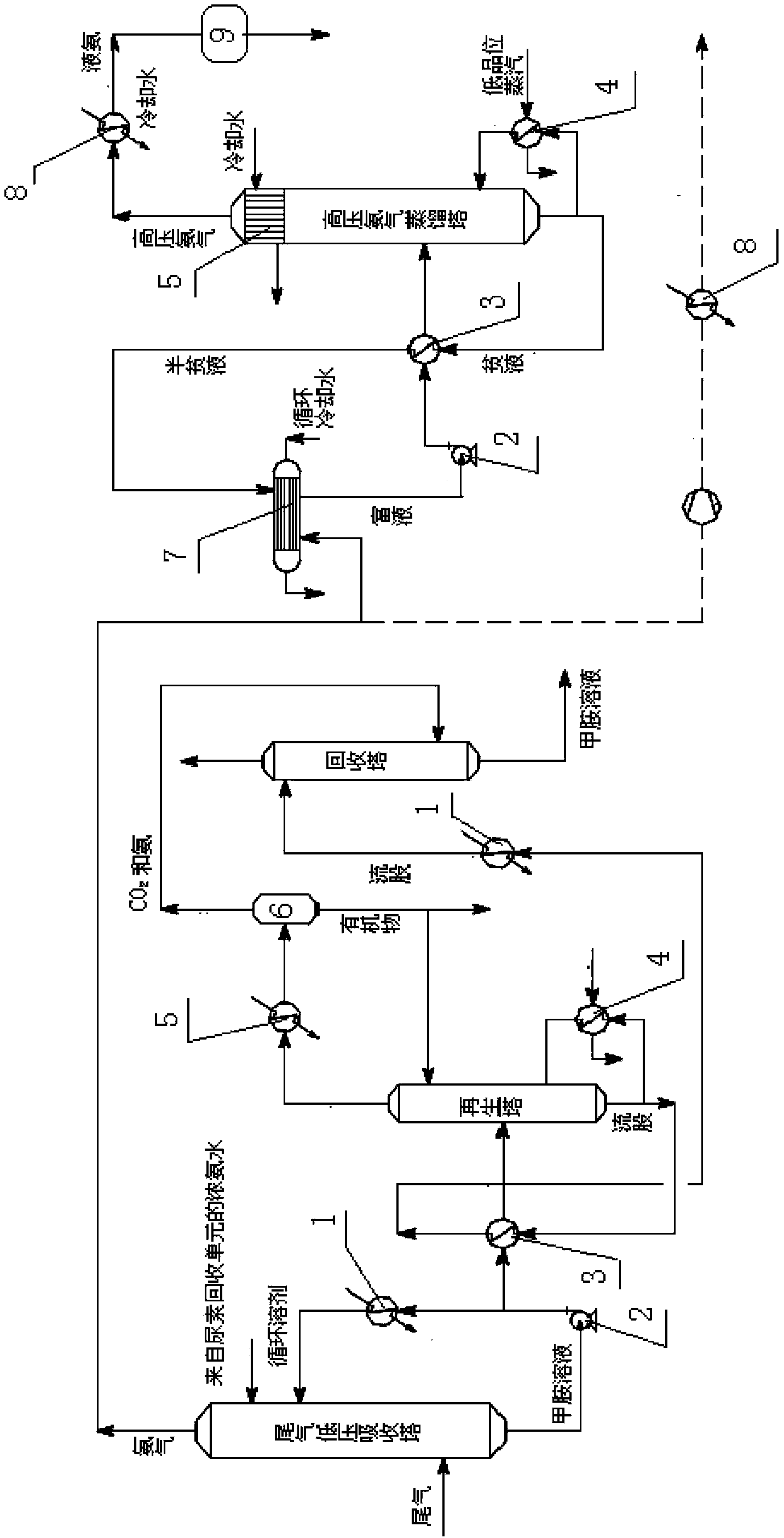

[0029] The following combination figure 1 with figure 2 , the process flow of the present invention is further described.

[0030] Such as figure 1 As shown, after the raw material fatty alcohol and urine are mixed, they enter the carbonate synthesis unit to obtain carbonate products. The synthesis tail gas enters the tail gas recovery system and is absorbed by the concentrated ammonia water from the urea recovery unit to obtain clean ammonia gas, which enters the ammonia absorption system. device 7, such as figure 2 As shown, it is absorbed by the lean liquid (aqueous solution with low ammonia concentration) from the downstream. The operating temperature of the absorption is controlled by circulating cooling water, generally 37-45°C. The absorption pressure depends on the upstream saturated ammonia pressure. After the absorbed rich liquid (aqueous solution with high ammonia concentration) is pressurized by the booster pump 2, after being heated by the downstream lean liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com