Electrostatic spraying and dust-removing system

An electrostatic spray dust removal and electrostatic spray technology, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of large water consumption, poor filtration efficiency of small particles, and low filtration efficiency of wet dust removal. Wide range of dust removal particle size, low water consumption and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

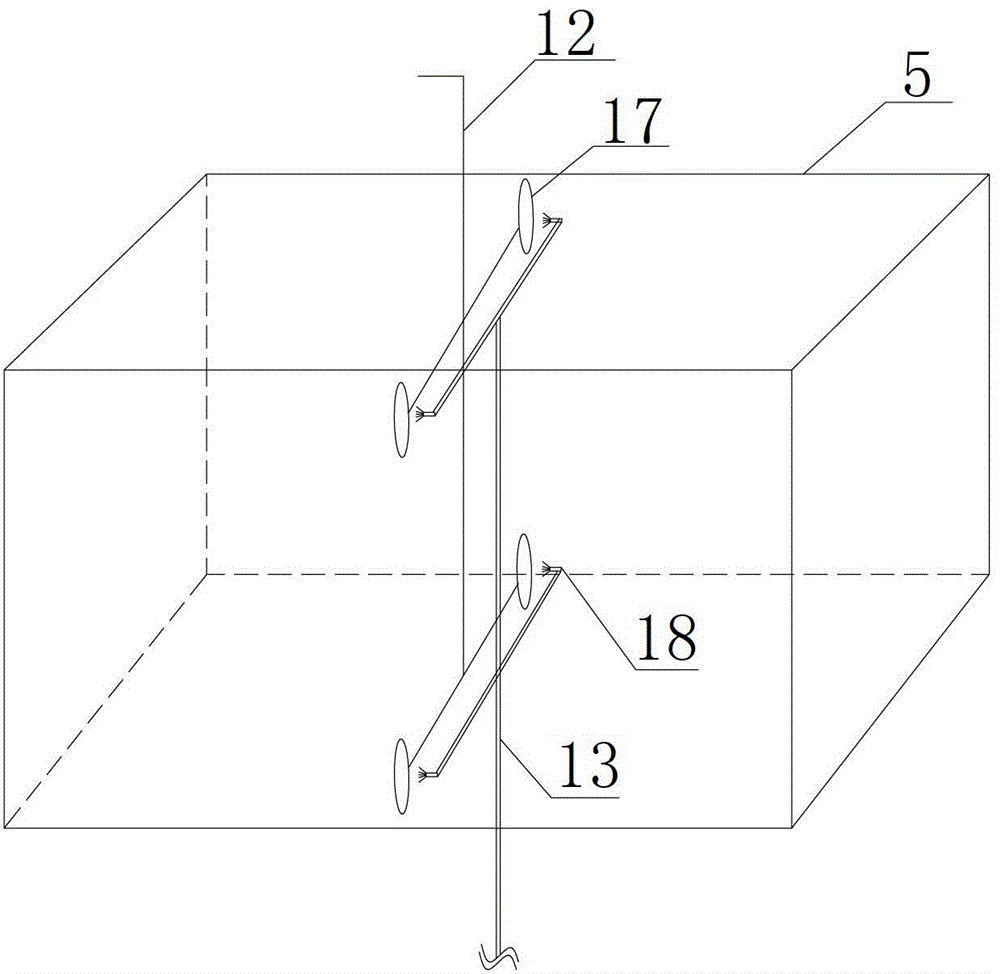

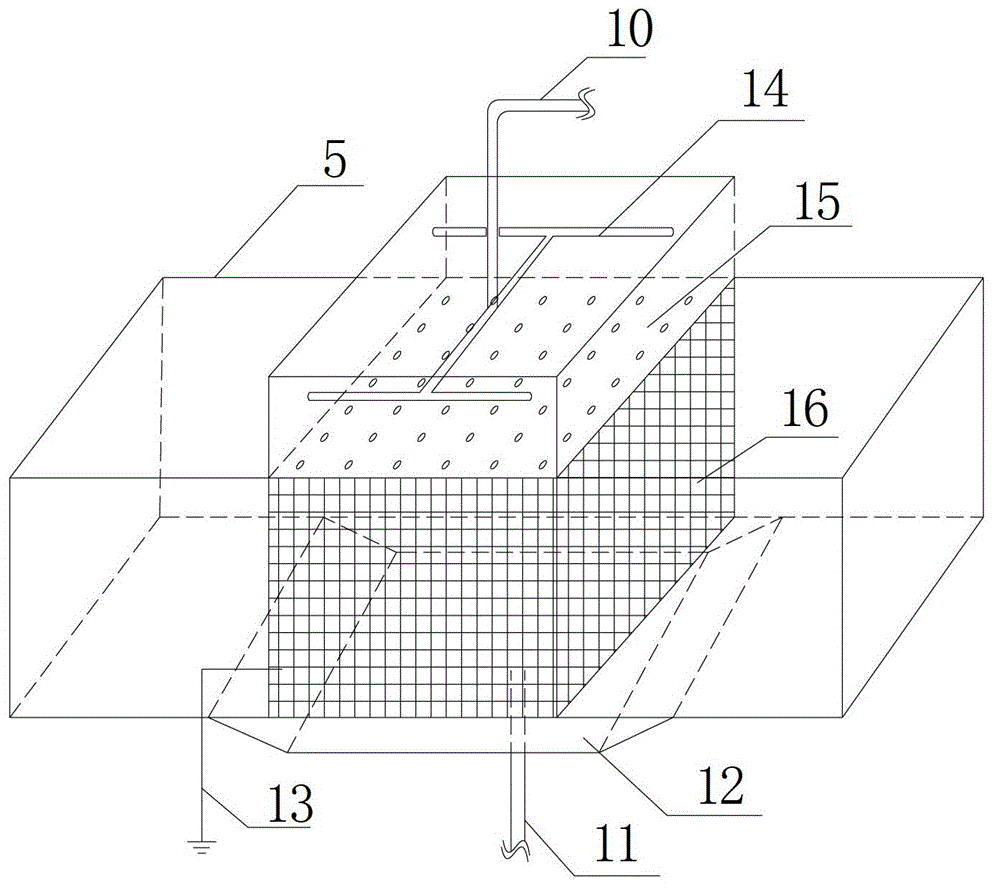

[0019] An electrostatic spray dust removal system such as figure 1 As shown, it includes a housing 2, an air distributor 3, an electrostatic spray device 4, a filter dust collection and washing device 5 and a dehydrator 6. One end of the housing is set as the dust removal system inlet 1, and the end is set as the dust removal system outlet 7. Inside the housing Air distributor 3, electrostatic spray device 4, filter dust collection washing device 5 and dehydrator 6 are arranged in sequence; electrostatic spray device such as figure 1 , figure 2 As shown, at least one atomizing nozzle 18 is connected on the water supply pipe one 9, and the water supply of the atomizing nozzle is introduced from the outside of the system by the water supply pipe one 9. There is a high-voltage electrostatic ring 17 in front of each atomizing nozzle 18, and the high-vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com