Enzymolysis product of corn protein, and preparation method and application thereof

A technology for corn gluten and enzymatic hydrolysis products, applied in the field of enzymatic hydrolysis products of corn gluten and its preparation, can solve the problems of complex composition of corn gluten meal, poor food functional properties, rough taste, etc. good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 prepares the enzymatic hydrolysis product of zein

[0016] The steps are: take 1 kg of corn gluten powder, add 4 times the amount of water, stir evenly, then add 0.05% of the weight of corn gluten compound protease (composed of equal mass of acid protease, neutral protease and flavor protease), and stir Control the enzymatic hydrolysis temperature at 45°C and pH value of 6.5. After enzymatic hydrolysis for 10 hours, heat to boiling to inactivate, filter, decolorize with activated carbon to obtain enzymatic protein solution, vacuum concentrate into a paste product with a water content of about 20%, and then pass Spray drying to obtain a powder product with a water content of about 5%, and then conventional granulation to obtain a granular product, which is the enzymatic hydrolysis product of zein.

Embodiment 2

[0017] Embodiment 2 prepares the enzymatic hydrolysis product of zein

[0018] Get 1 kg of corn gluten powder, add 4 times the amount of water, stir evenly, then add 0.05% composite protease (composed of equal mass of acid protease and neutral protease) of the corn gluten weight, and control the enzymatic hydrolysis temperature 45°C under stirring, PH value 6.5, enzymatic hydrolysis for 2 hours, then add 0.02% of the weight of zein flavor protease, and then enzymatic hydrolysis for 5 hours, heat to boiling to inactivate, filter and decolorize with activated carbon to obtain enzymatic protein solution, vacuum concentrate to a water content of About 20% of the paste product, and then spray-dried to obtain a powder product with a water content of about 5%, and then conventionally granulated to obtain a granular product, which is the enzymatic hydrolysis product of zein.

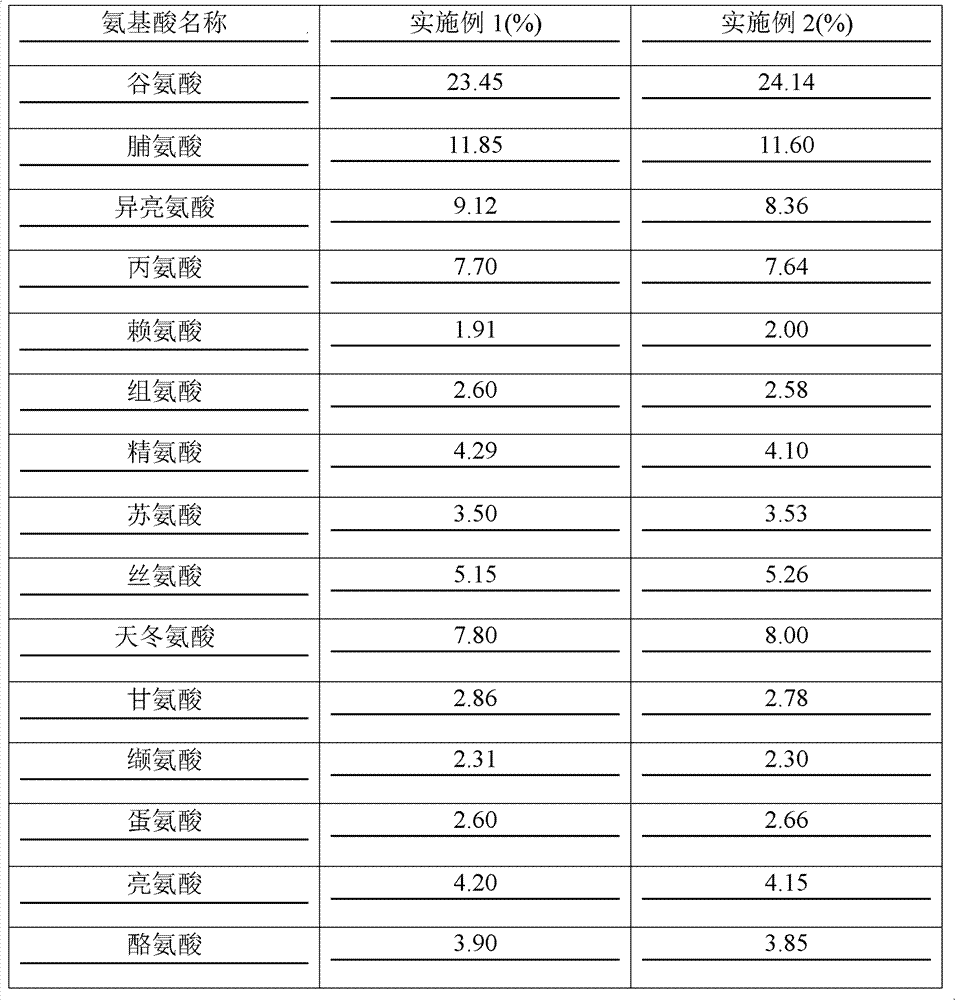

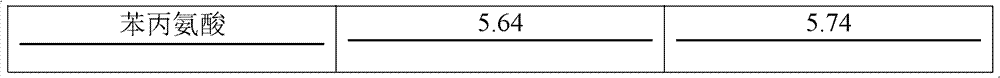

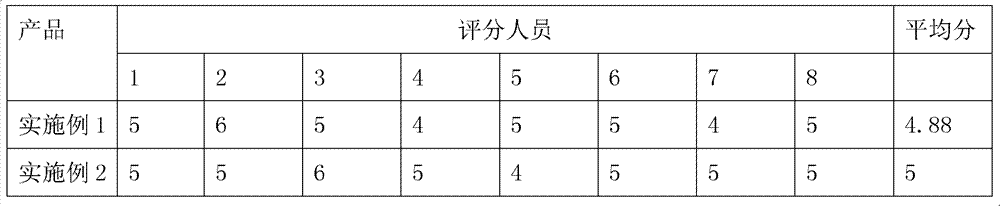

[0019] Get the enzymatic hydrolyzate prepared by above-mentioned two kinds of preparation methods to analyze,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com