Manufacturing method for cheap transparent conducting film

A technology of transparent conductive film and manufacturing method, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problem of insufficient stability of the film, achieve the effects of easy large-area deposition, easy-to-obtain materials, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for manufacturing an inexpensive transparent conductive film, comprising the process steps of preparing a coating solution, cleaning a base material, coating, making an electrode, annealing or energizing, aging and shaping, and is characterized in that:

[0031] (1) Preparation of coating solution

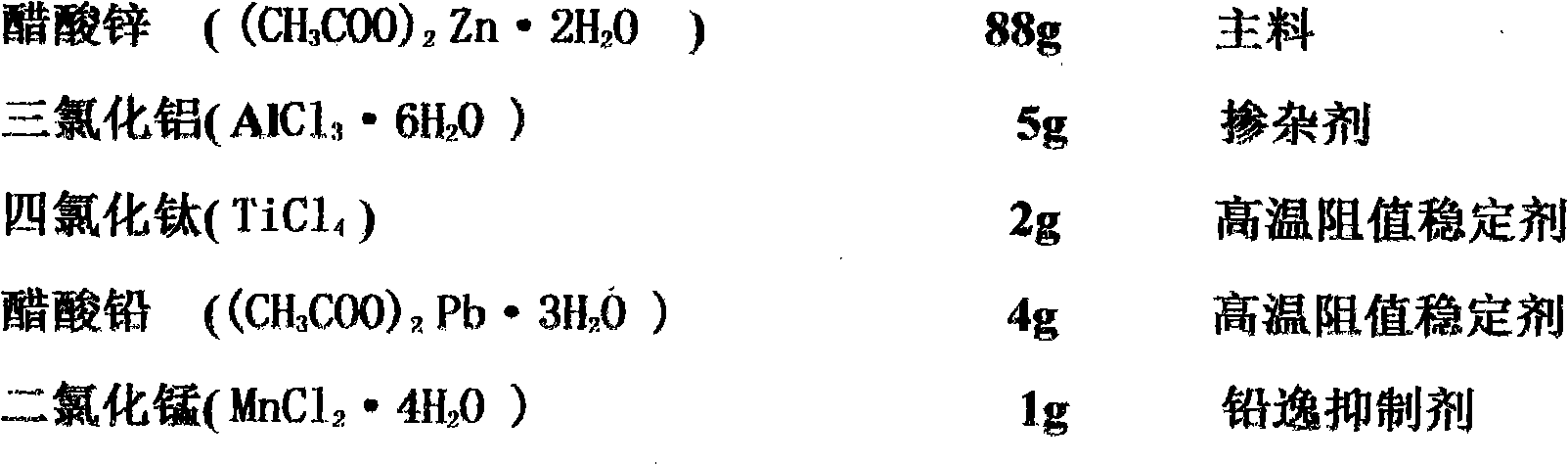

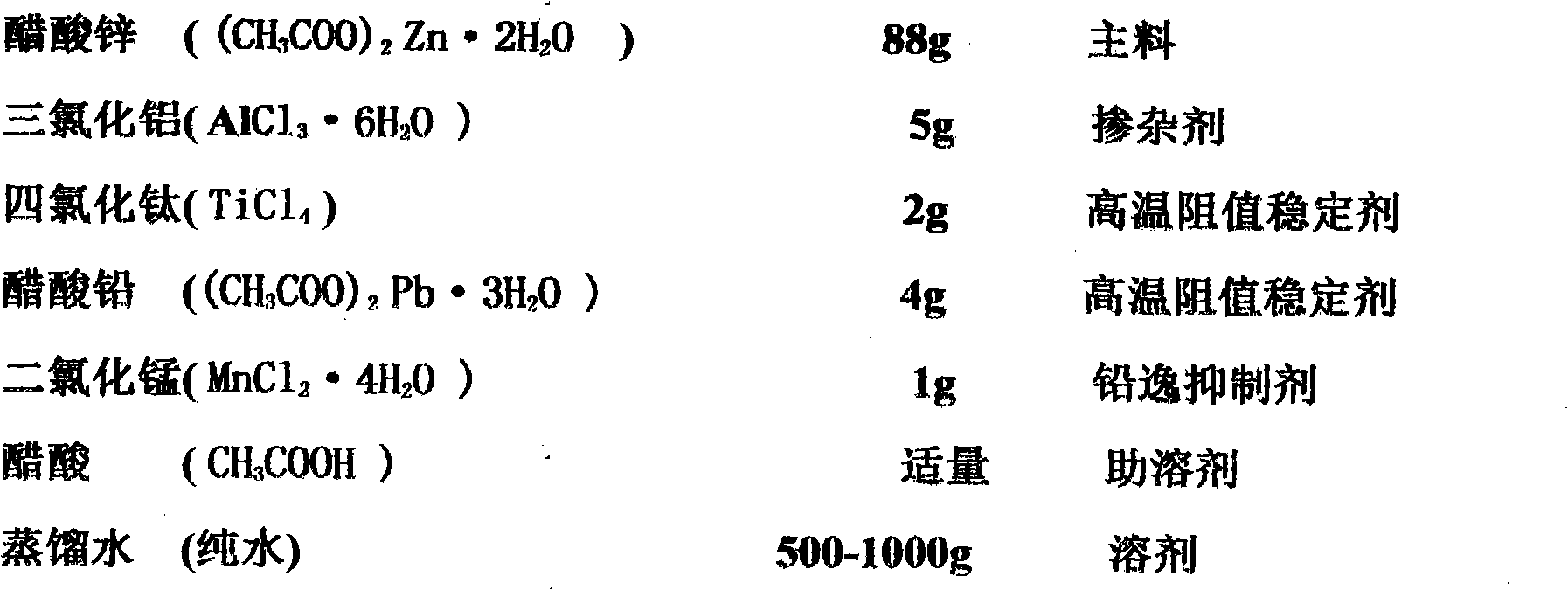

[0032] ①Coating solution formula component weight ratio:

[0033]

[0034] ②Coating solution preparation steps:

[0035] A, Acidify the distilled water with acetic acid, cover it for later use;

[0036] B, take the titanium tetroxide solution according to the formula, cover it for later use;

[0037] C. Weigh zinc acetate, aluminum trichloride, lead acetate, and manganese dichloride according to the formula, dissolve them in acidified distilled water, slowly drop into titanium tetrachloride solution under stirring, fully stir evenly, and put them into a plastic container with a cover. In a bucket, cover and set aside;

[0038] (2) Clean the substrate

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com