Supporting device for arched steel among beam columns

A support device and arch steel technology, which is applied to arch structures, building components, dome structures, etc., can solve the problem of reducing beam section size and reinforcement amount, large main beam section size and reinforcement amount, and reducing Problems such as the internal force of the main beam, to achieve the effect of reducing the cost of the project, reducing the internal force, reducing the size of the beam section and the amount of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

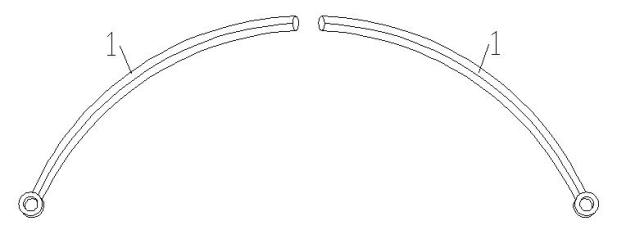

[0030] see Figure 1-Figure 5 , the arched steel support device between beams and columns is composed of two arc-shaped steel pipes (1), frame columns (2) and main beams (5), characterized in that one end of the two arc-shaped steel pipes (1) is respectively It is hinged with the frame columns (2) on both sides, and the other end is hinged with the lower part of the midpoint of the main beam (5) to form a two-hinge arc arch.

Embodiment 2

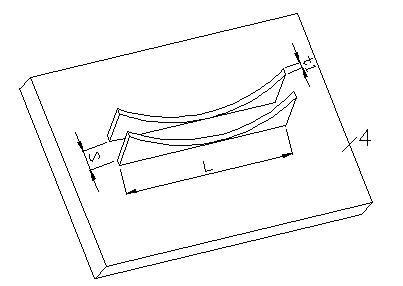

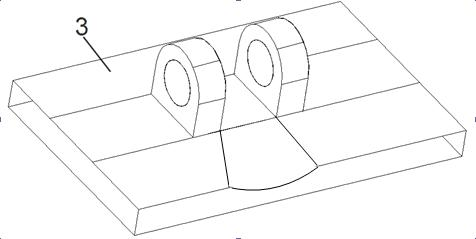

[0032] see Figure 1-Figure 5 , this embodiment is basically the same as the first embodiment, the special feature is: the structure of connecting the two arc-shaped steel pipes (1) with the frame column (2) and the main beam (5) is: the two arc-shaped steel pipes (1) are connected A small steel ring is welded to one end of the steel pipe (1), a hinge seat (3) is embedded in the frame column (2), and a shaft pin is inserted into the inner hole of the small steel ring at the end of the steel pipe (1). and the pin hole on the hinge seat (3) to realize the hinge connection between the steel pipe (1) and the frame column (2), and the other end of the steel pipe (1) is embedded with one of the midpoints of the main beam (5). The parts (4) are connected by welding to realize the hinge connection between the steel pipe (1) and the main beam (5).

Embodiment 3

[0034] see Figure 1-Figure 6 , the arched steel support device between beams and columns, including figure 1 Two rounded steel tubes shown. Pre-embedded below the midpoint of the main beam figure 2 Embedded parts shown, embedded on the side of the frame column image 3 The hinge seat shown, on the premise of meeting the clearance requirements of the underground garage, is set between the frame column and the main beam through the embedded parts as shown in the figure below. Figure 4 The arched steel support is shown, one end of the arched steel tube is hinged with the frame column, and the other end is hinged with the lower part of the midpoint of the main beam. A shaft pin is inserted into the inner hole of the small steel ring at the end of the arched steel pipe and image 3 The pin hole on the embedded part as shown, realizes the hinge connection between one end of the arched steel pipe and the frame column. The other end of the arched steel pipe is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com