High-gloss flame-retarded polypropylene composite and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of high-gloss flame-retardant polypropylene composite materials and its preparation, can solve problems such as difficulty in taking both flame retardancy and high gloss, and restrict the development of polypropylene modification technology, and achieve good The effect of formability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

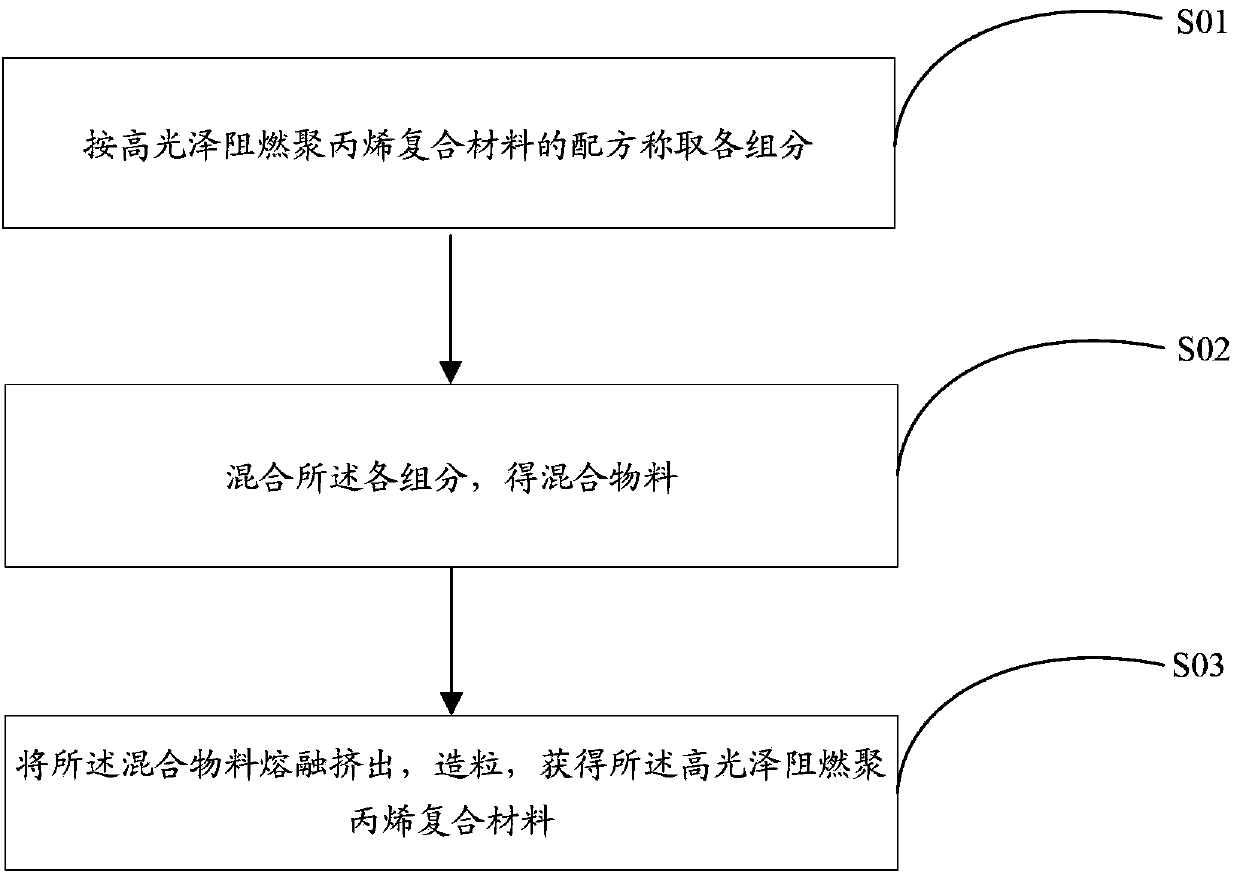

[0039] see figure 1 , showing a method for preparing a high-gloss flame-retardant polypropylene composite material according to an embodiment of the present invention, which includes the following steps:

[0040] S01: Weigh each component according to the formula of the above-mentioned high-gloss flame-retardant polypropylene composite material;

[0041] S02: mixing the components to obtain a mixed material;

[0042] S03: Melt-extrude the mixed material and pelletize to obtain the high-gloss flame-retardant polypropylene composite material.

[0043] Specifically, in step S01, all materials are weighed accurately, accurate to 0.001 kilogram. The high-gloss flame-retardant polypropylene composite material and the preferred content and types of each component in the formula are as above, and will not be repeated here to save space.

[0044]Step S02 specifically includes adding polypropylene, linear low density polyethylene, compatibilizer, flame retardant, brightener, antioxid...

Embodiment 1

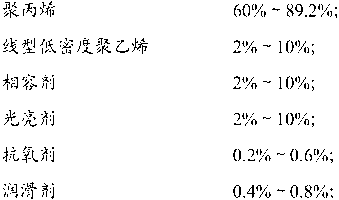

[0049] The components and weight percentages of the high-gloss flame-retardant polypropylene composite material of this embodiment are:

[0050] Polypropylene 89.2%;

[0051] Linear low density polyethylene 2%;

[0052] Compatibilizer 2%;

[0053] Flame retardant 4.2%;

[0054] Brightener 2%;

[0055] Antioxidant 0.2%;

[0056] Lubricant 0.4%.

[0057] Wherein, the content of the flame retardant bisphenol A bis(diphenyl phosphate) is 0.2%.

[0058] Mix the above-mentioned components evenly to obtain a mixed material, and then put the mixed material in a twin-screw extruder for melt extrusion and granulation. ℃, 160℃ in the fourth zone, and 190℃ in the machine head to obtain high-gloss flame-retardant polypropylene composite materials.

Embodiment 2

[0060] The components and weight percentages of the high-gloss flame-retardant polypropylene composite material of this embodiment are:

[0061] Polypropylene 81.9%;

[0062] Linear low density polyethylene 4%;

[0063] Compatibilizer 4%;

[0064] Flame retardant 5.3%;

[0065] Brightener 4%;

[0066] Antioxidant 0.3%;

[0067] Lubricant 0.5%.

[0068] Wherein, the content of the flame retardant bisphenol A bis(diphenyl phosphate) is 0.3%.

[0069] Mix the above-mentioned components evenly to obtain a mixed material, and then put the mixed material in a twin-screw extruder for melt extrusion and granulation. ℃, 170℃ in the fourth zone, and 185℃ in the machine head to obtain high-gloss flame-retardant polypropylene composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com