Method for performing hydrophilic modification on polyacrylate or copolymer thereof, and product and application of polyacrylate or copolymer thereof

A polyacrylate, hydrophilic modification technology, used in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problem of inability to further derive separation media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

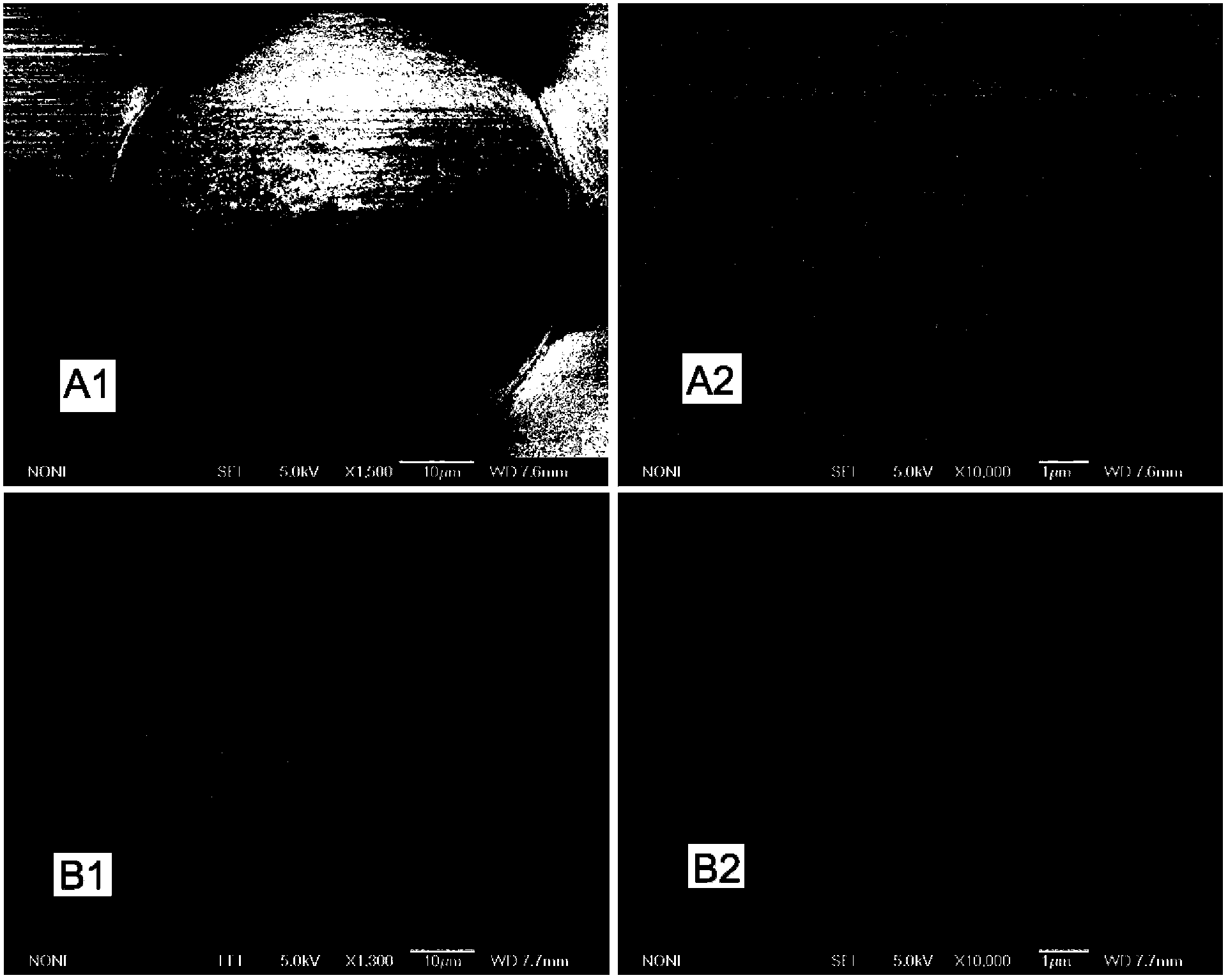

[0065] 1) Super-large pore PGMA-DVB microspheres pretreated in DMSO

[0066] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 10 mL of DMSO, shake in a 120 rpm shaker for 2 hours at room temperature, then perform suction filtration and wash with the same volume of DMSO. After washing, remove the solvent Suction filtration until there is no obvious solvent on the surface of the microspheres.

[0067] 2) PEI bonded to the surface of PGMA-DVB microspheres (Mw=1800)

[0068] Weigh 1.0g PEI and put it into a 100mL three-neck bottle, then add 50mL DMSO to it, under mechanical stirring at 120rpm, add the microspheres after swelling treatment in step 1) in Example 1, raise the temperature to 80°C, and keep the reaction at this temperature After 24 hours, after the reaction, use a G4 sand core funnel to filter under reduced pressure, and at the same time wash with 500mL of 80°C hot water until the washing liquid is neutral.

[0069] 3) Reinforceme...

Embodiment 2

[0074] 1) Super-large pore PGMA-DVB microspheres pretreated in DMSO

[0075] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 20 mL of DMSO, shake at room temperature on a 120 rpm shaking shaker for 2 hours, perform suction filtration, and wash with the same volume of DMSO. After washing, the solvent Suction filtration until there is no obvious solvent on the surface of the microspheres.

[0076] 2) ethylenediamine bound to the surface of PGMA-DVB microspheres

[0077] Weigh 2.0g of ethylenediamine into a 100mL three-neck flask, then add 50mL of DMSO to it, under mechanical stirring at 120rpm, add the microspheres after swelling treatment in step 1) in Example 2, heat up to 60°C, at this temperature Keep the reaction for 24 hours. After the reaction, use a G4 sand core funnel to filter under reduced pressure, and at the same time wash with 500mL deionized water until the washing liquid is neutral.

[0078] 3) Reinforcement of PGMA-DVB m...

Embodiment 3

[0083] 1) Pretreatment of ultra-large pore PGMA-DVB microspheres in DMF

[0084] Accurately weigh 1.0 g of PGMA-DVB microspheres into a 50 mL Erlenmeyer flask, then add 15 mL of DMF, shake at room temperature on a 120 rpm shaking shaker for 2 hours, perform suction filtration, and wash with the same volume of DMF. After washing, the solvent Suction filtration until there is no obvious solvent on the surface of the microspheres.

[0085] 2) Diethylenetriamine bonded to the surface of PGMA-DVB microspheres

[0086] Weigh 1.0g of diethylenetriamine and put it into a 100mL three-necked flask, then add 50mL of DMSO to it, under mechanical stirring at 120rpm, add the microspheres after the swelling treatment in step 1) in Example 3, and heat up to 70°C. Keep the reaction for 24 hours. After the reaction is over, filter under reduced pressure with a G4 sand core funnel while it is hot, and wash with 500mL deionized water until the washing liquid is neutral.

[0087] 3) Reinforcemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com