Screening-combing combined type dry method acetylene generating unit

A dry acetylene and combined technology, applied in the direction of organic chemistry, hydrocarbons, hydrocarbons, etc., can solve the problems of wrapping reaction, affecting production efficiency and production continuity, unable to separate calcium carbide and ash powder, etc., to achieve reaction The effect of improving efficiency and increasing equipment production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

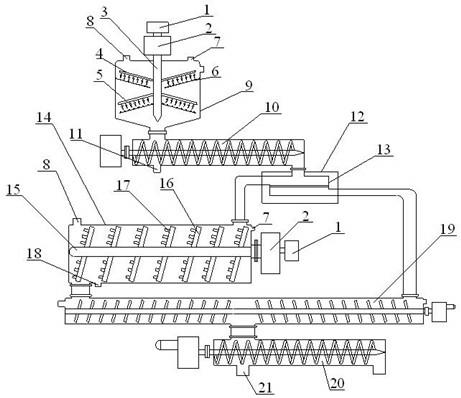

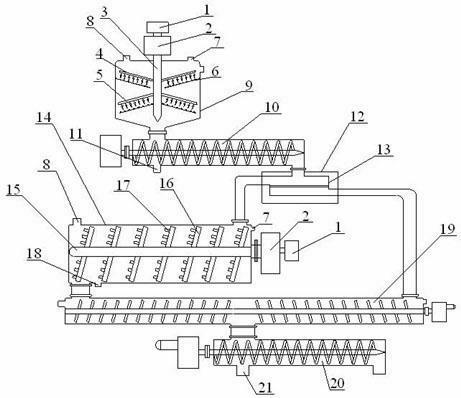

[0025] Such as figure 1 As shown, the screening and combing combined dry-process acetylene generating unit of the present invention includes a screening generator, an isolation bin, a combing generator, a fine distribution machine 19 and a slag discharger 20 connected sequentially through pipelines; The isolation bin is also connected to the precision distributing machine 19 through pipelines.

[0026] In order to make the calcium carbide reacted in the screening type generator smoothly enter the isolation bin, a screw conveyor 10 is provided between the screening type generator and the isolation bin, and a screw conveyor 10 is provided below the feeding port of the screw conveyor. The first sampling port 11 is provided, and the sampling port can collect the calcium carbide particle size after the reaction of the sieving type generator. After analysis, the speed reducer and the water intake of the sieving type generator can be adjusted according to the results, so that the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com