Method for densifying porous silicon carbide base

A silicon carbide and porous technology, which is applied in the field of densification of porous silicon carbide substrates, can solve the problems of complexity and many steps, and achieve the effect of improving purity and reducing harmful impurity elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185] Material:

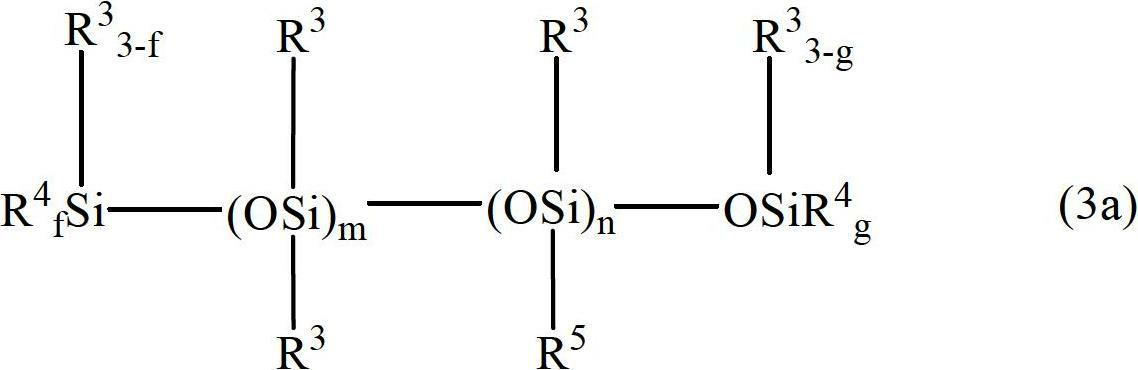

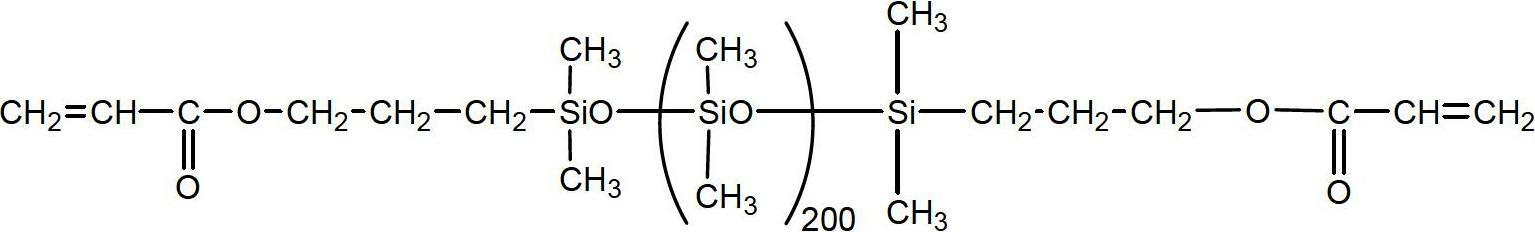

[0186] (A) 100 parts by mass of a diorganopolysiloxane having an alkenyl group in one molecule represented by the following formula,

[0187] [chemical 13]

[0188]

[0189] (where n and m are n / m=4 / 1, and the viscosity of the siloxane at 25° C. is 600 mPa.s), and,

[0190] (B) 0.5 parts by mass of benzoyl peroxide,

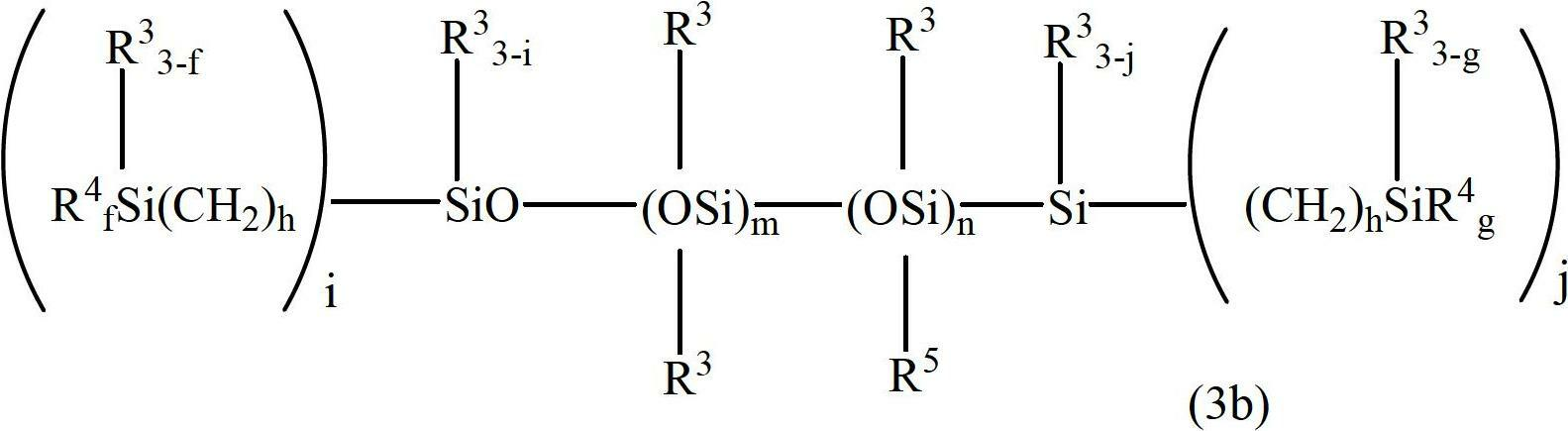

[0191] (C) 33 parts by mass of a diorganopolysiloxane having a hydrogen atom bonded to a silicon atom represented by the following formula,

[0192] [chemical 14]

[0193]

[0194] (D) 160 parts by mass of silicon carbide powder (average particle diameter: 2 μm)

[0195] (That is, an amount of 33% by volume of the entire silicone composition)

[0196] A porous silicon carbide substrate (20 mm long x 20 mm wide x 2 mm thick, 1.9 g, specific gravity: 2.38) with an average pore diameter of 5 μm was immersed in the composition to fully impregnate the substrate with the composition. The obtained silicone-impregnated porous silicon carbid...

Embodiment 2

[0206] Put the following formula:

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com