Textile industrial ethernet monitoring system and method thereof

A monitoring system, Ethernet technology, applied in transmission systems, digital transmission systems, data exchange networks, etc., can solve the problems of on-site electromagnetic interference, small number of transmission distance devices, out-of-sync monitoring product clocks, etc., to achieve enhanced stability and reliability, realize real-time monitoring, and improve management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

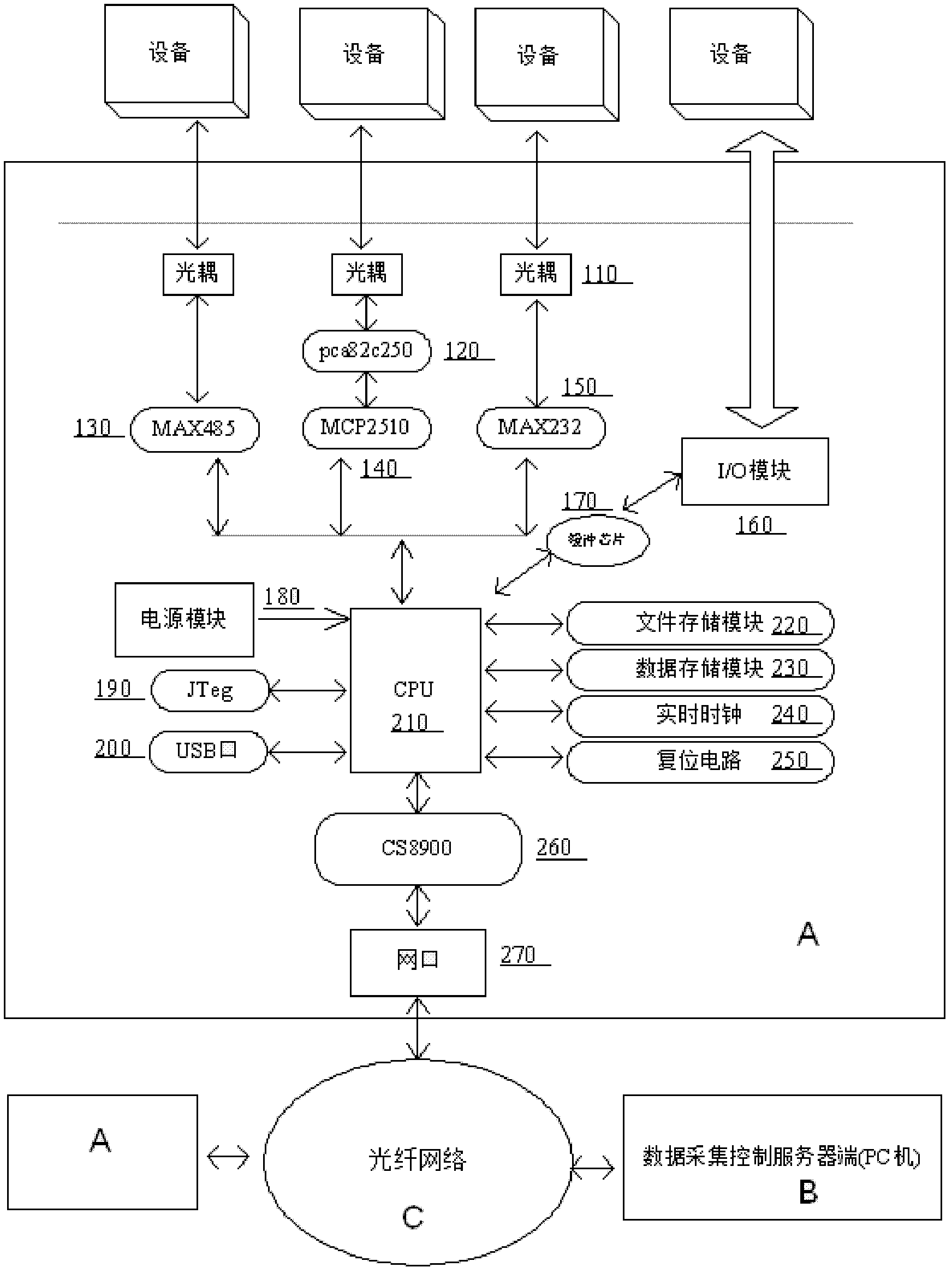

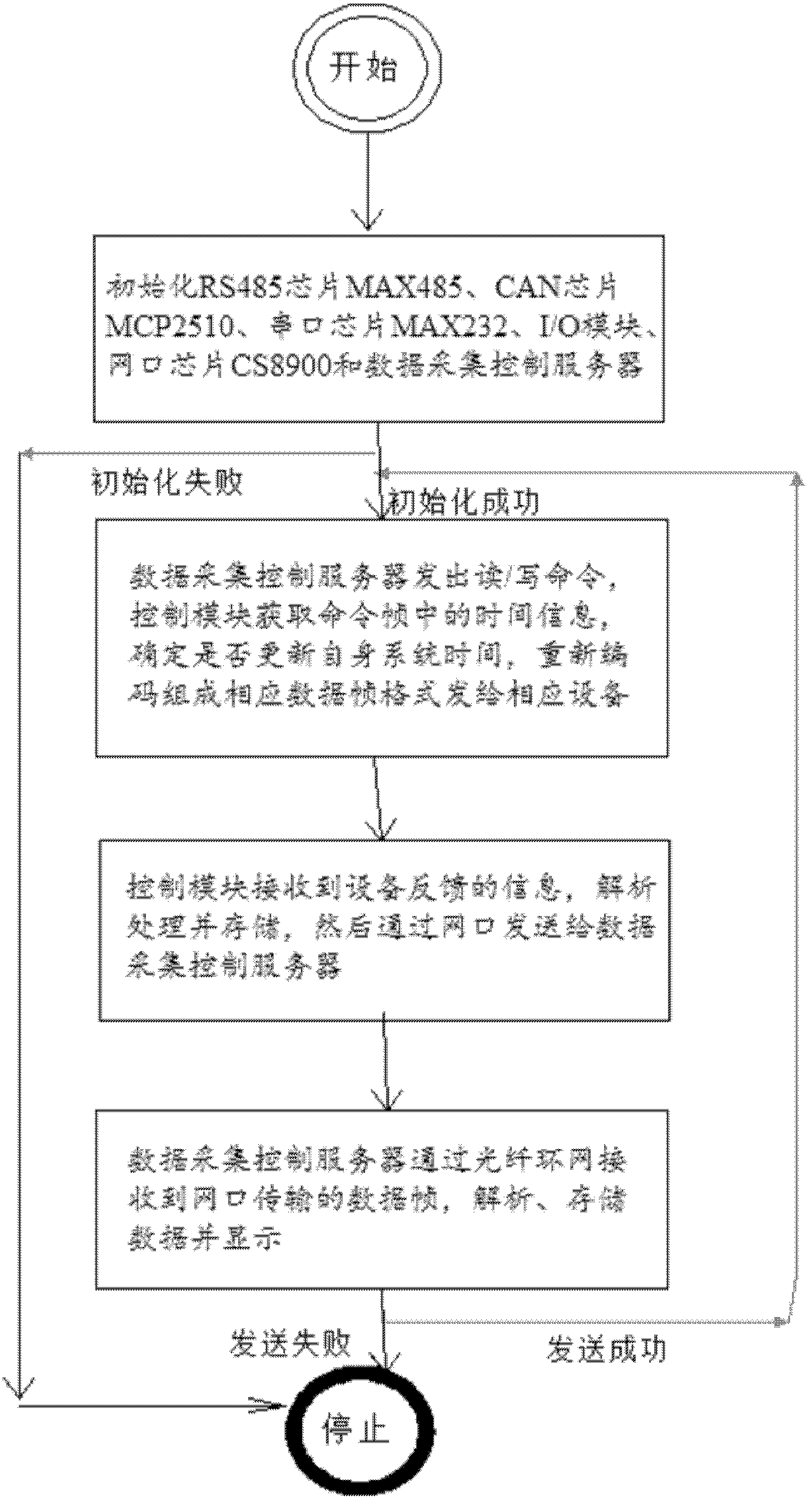

[0033] Such as figure 1 As shown, the textile industry industrial Ethernet monitoring system of the present invention includes a data acquisition control server B for sending data acquisition commands and receiving, parsing, and storing display device information, and the data acquisition control server B is connected through an optical fiber ring network C At least one monitoring module A, the monitoring module A includes a control module 210 and an interactive module connected to the control module 210, a power supply module 180, a file storage module 220, a data storage module 230, a real-time clock 240, a reset circuit 250, a network port chip 260;

[0034] The interaction module includes a plurality of protocol controllers connected to industrial equipment for interacting with different equipment;

[0035] The power module 180 is used for power supply;

[0036] The file storage module 220 and the data storage module 230 are used to store information of industrial equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com