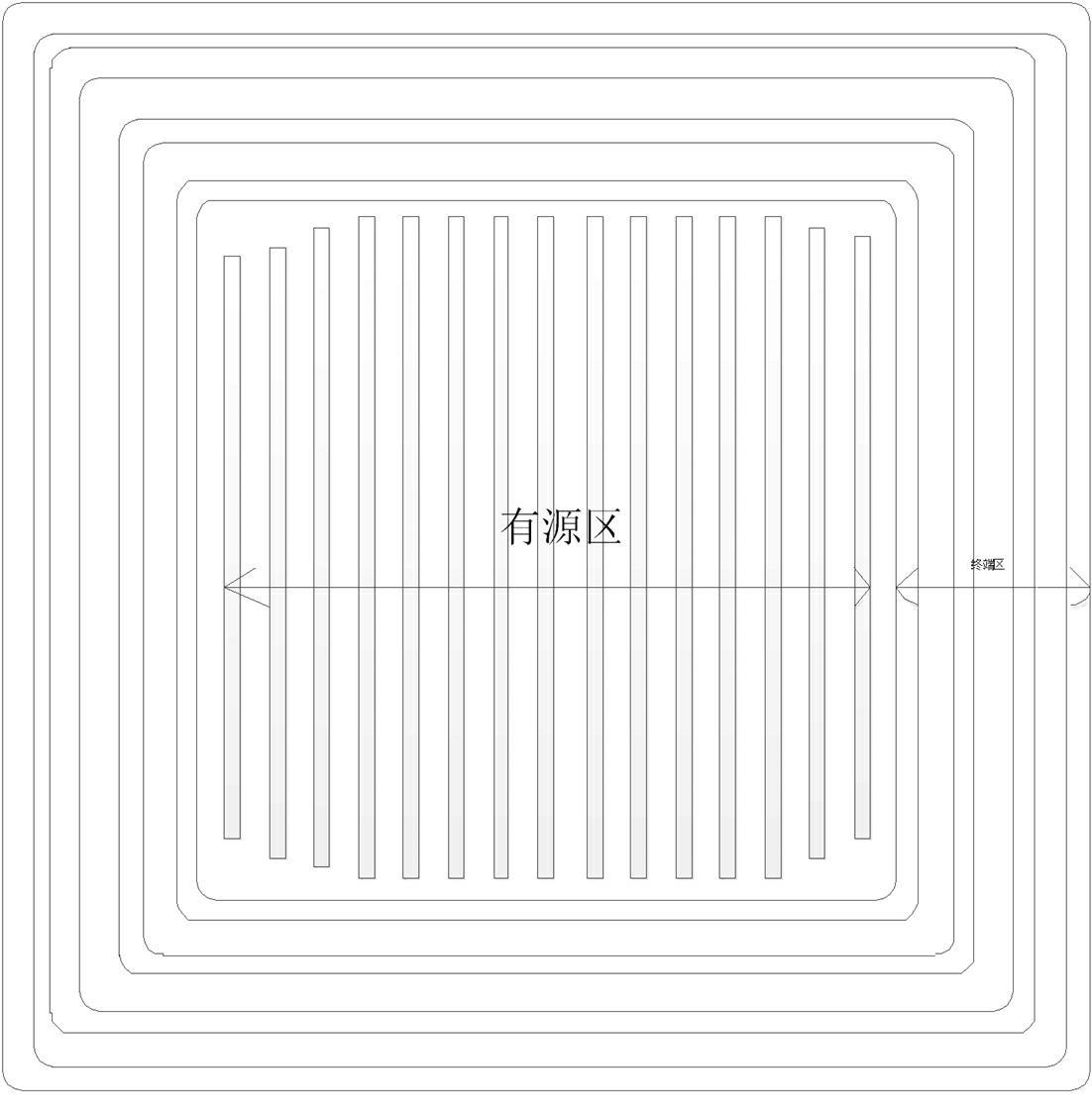

Super junction high-voltage power device structure

A high-voltage power device and device technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increased manufacturing cost and increased process difficulty, and achieve the effect of improving withstand voltage and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

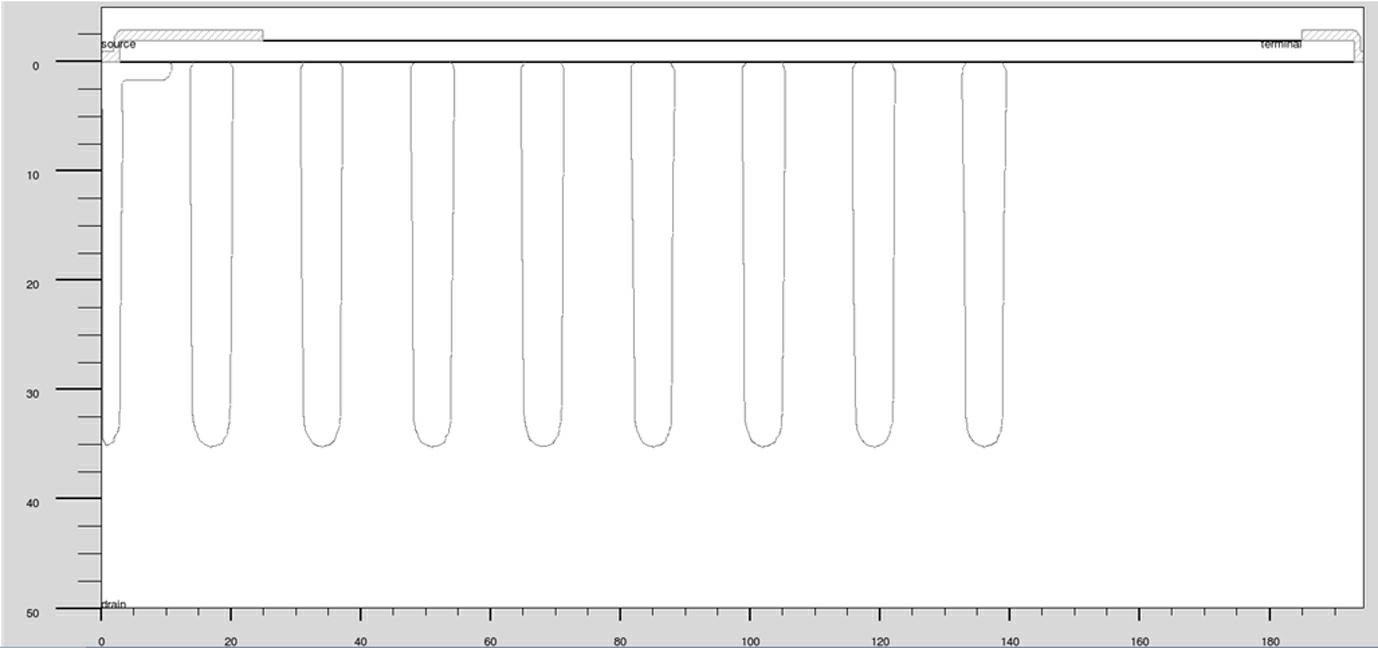

[0032] A MOSFET having a superjunction structure is illustrated, but the present invention is not limited to MOSFETs.

[0033] 1. Form a super junction structure on the wafer;

[0034] 2. Formation of field oxide layer;

[0035] 3. Form a gate oxide layer and form a polysilicon layer;

[0036] 4. Inject the p+ well to form a p+ ring;

[0037] 5. Form n+source region, n+ stop ring, deposit BPSG layer, and etch lead hole;

[0038] 6. Deposit the metal layer and etch.

[0039] In the present invention, the formation of the p+ ring and the p well is the same layer of photoresist, and the order described in this embodiment is not limited.

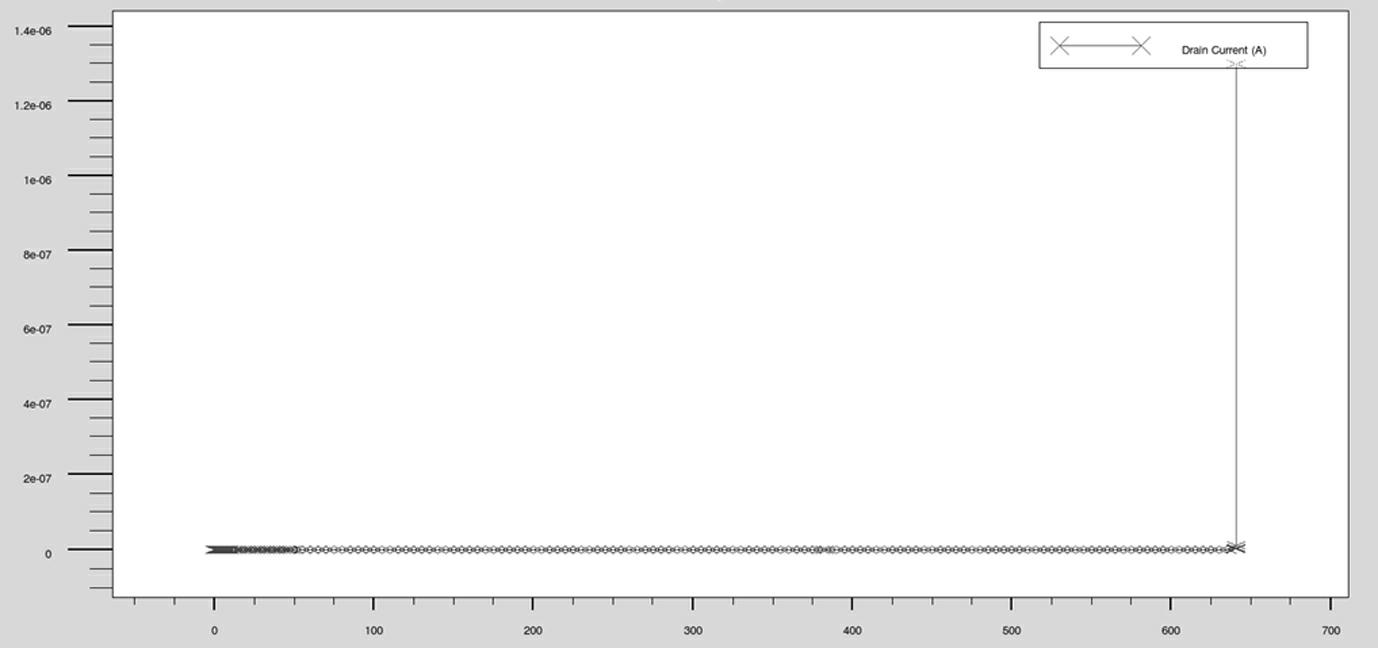

[0040] Take 700v super junction mosfet as an example:

[0041] In this example, the semiconductor of the first conductivity type is represented by an n-type semiconductor, and the semiconductor of the second conductivity type is represented by a p-type semiconductor.

[0042] The n-type substrate resistivity is 0.05ohm; the n-type epitaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com