Multi-operating mode frame type portable landslide testing device for geomechanical model

A technology of geomechanics and test equipment, applied in soil material testing, material inspection products, geophysical measurement, etc., can solve the problems of less landslide simulation research, bulky structure, inconsistent seepage field of landslides, etc., to overcome the long test period and load The method is simple and the effect of reducing the production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

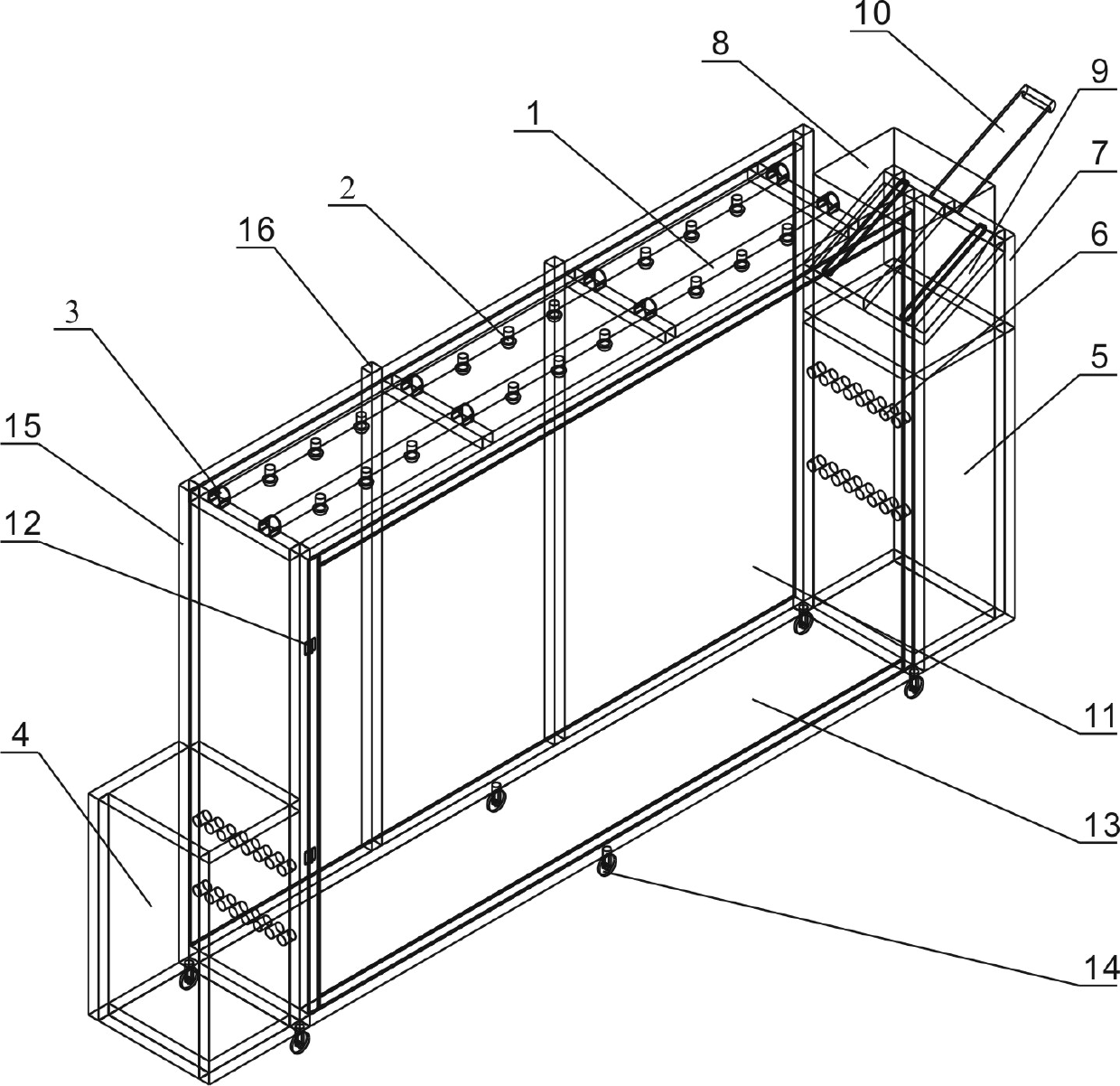

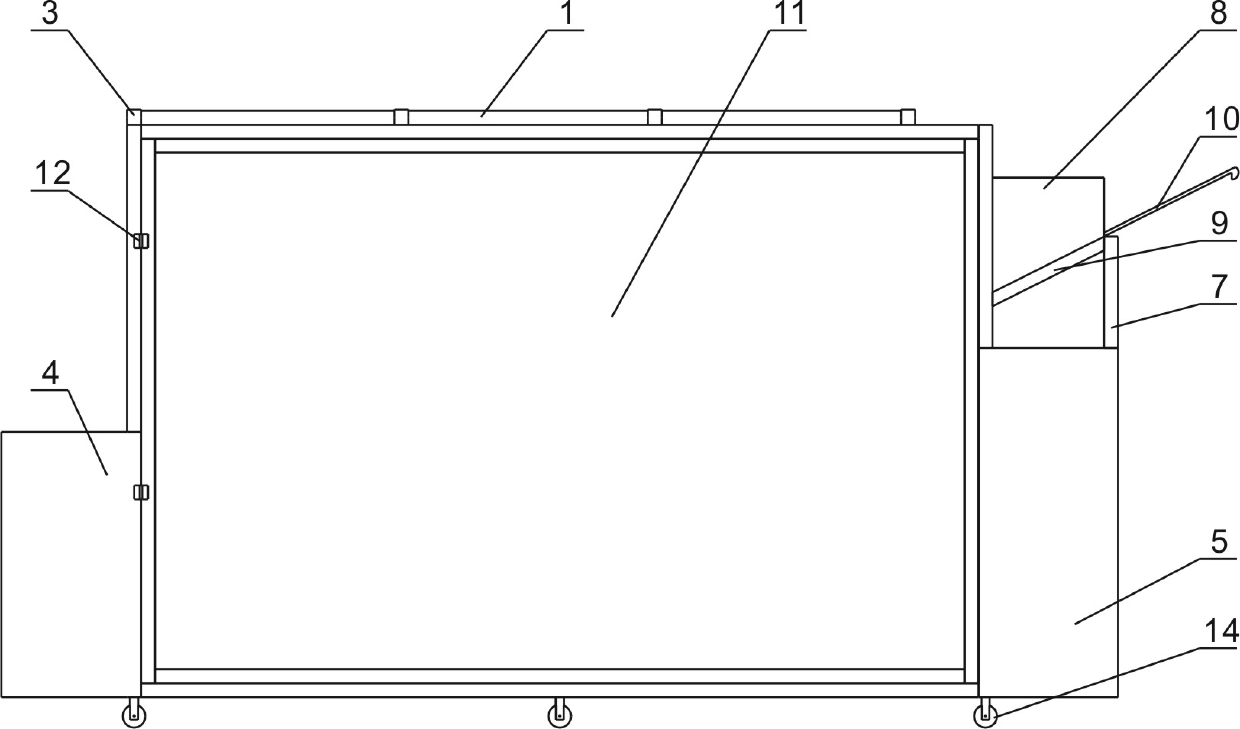

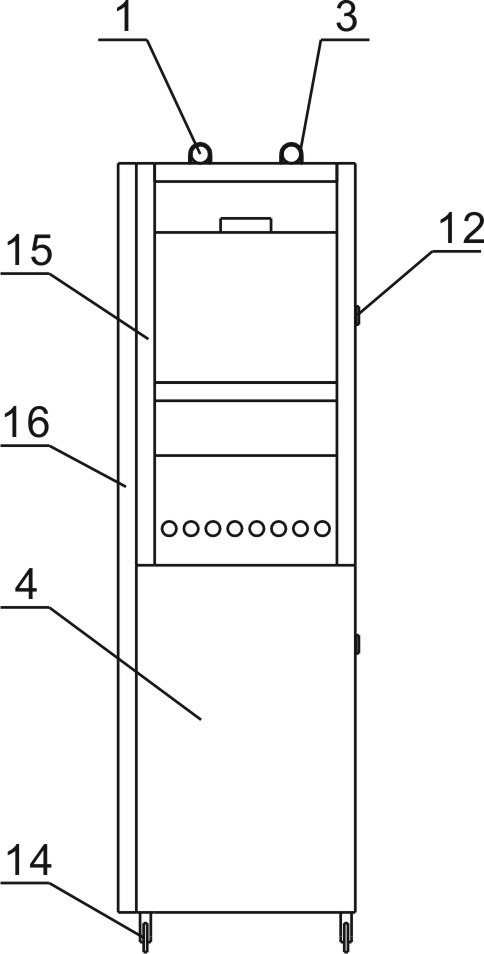

[0042] Such as Figure 1 to Figure 5 As shown, a multi-working-condition frame-type landslide geomechanics model portable test device of the present invention includes a frame-beam type test bench, a rainfall simulator, a reservoir water level regulator and a self-weight horizontal loading mechanism.

[0043]The frame-beam test bench is mainly composed of a cuboid frame, a front panel 11 , a rear panel 15 and a bottom plate 13 . Wherein, the front panel 11 is a toughened glass panel fixed on the metal frame, and one side of the front panel 11 is connected with the cuboid frame by a fixed hinge 12, forming an open movable structure, which can be fixed by a mortise lock or other structures when closed. When preparing the landslide model, the front panel 11 can be opened to provide a working space, and the front panel 11 can be closed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com