Online monitoring method for covert faults and joint process defects of power cable

A technology of hidden faults and process defects, applied in the field of electric power, can solve problems such as economic waste, large impact, and hidden safety hazards, and achieve the effects of accurate fault location, low accuracy, and comprehensive monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and embodiments.

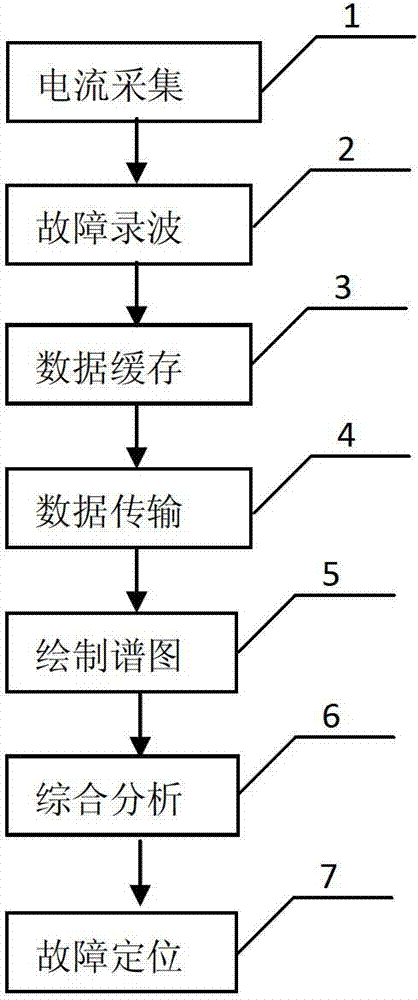

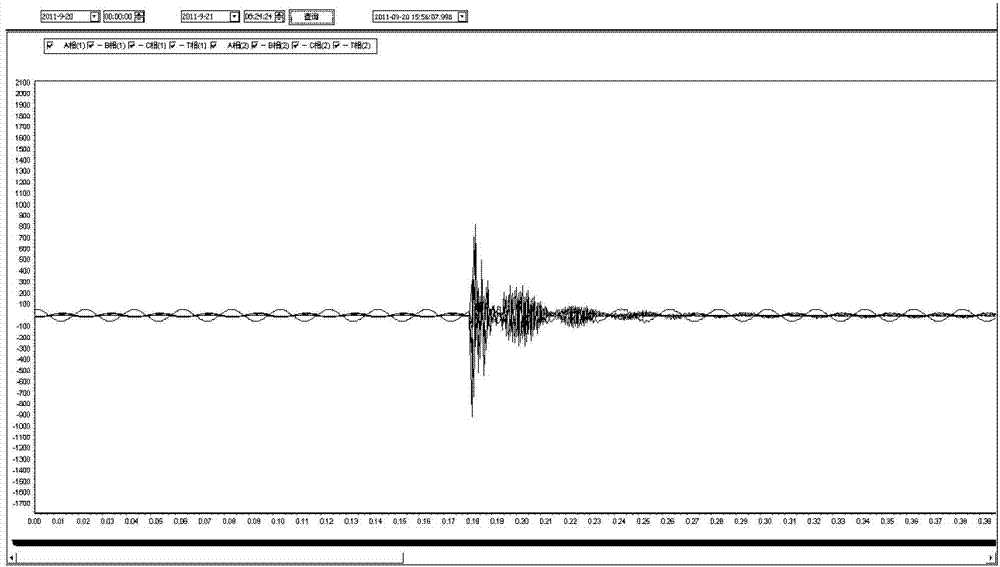

[0034] Such as figure 1 As shown, current collection 1: real-time online collection of the cable sheath ground current depends on the fault recording device. The fault recording device is installed at each direct grounding point along the high-voltage cable, using long-distance low-voltage DC power supply and long-distance high-speed transmission. Hook each recorder to the same grounding line to monitor the circulating current of all grounding points on a cable when the cable runs online, and the monitoring points are more comprehensive.

[0035] Fault recorder 2: Each fault recorder can monitor the grounding current of multiple protection layers. When one of the terminals on a line exceeds the current mutation threshold, all fault recorder terminals of this line will start waveform data recording. Enter the fault recording process.

[0036] Data buffer 3: Each fault reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com