Preparation method of porous nickel oxide/tin dioxide micro/nano spheres

A technology of tin dioxide and micro-nano spheres, which is applied in the direction of material resistance, etc., can solve the problems of inability to realize the regulation of the morphology and microstructure of tin dioxide nanocrystals, restrict gas-sensing characteristics, and the response sensitivity is not high enough to achieve porous The effect of uniform pore size distribution, stable sensitive performance and high sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Dissolve the raw material of sodium stannate in water, adjust the pH value of the solution to 12.60 with 5.0M sodium hydroxide, prepare 30 ml of 0.5M sodium stannate solution, then add 3 ml of concentrated ammonia water (mass percentage concentration is 25.0-28.0% ), under magnetic stirring at a speed of 60 rpm, add 15 ml of 1.0M nickel sulfate solution to obtain a mixed solution;

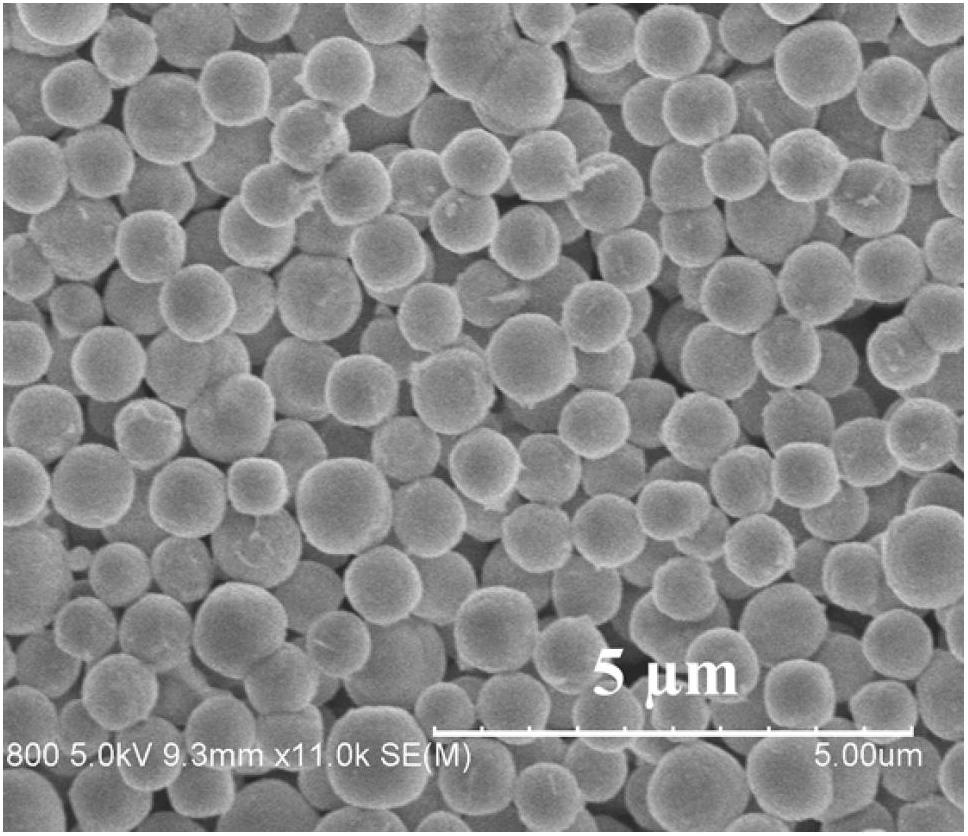

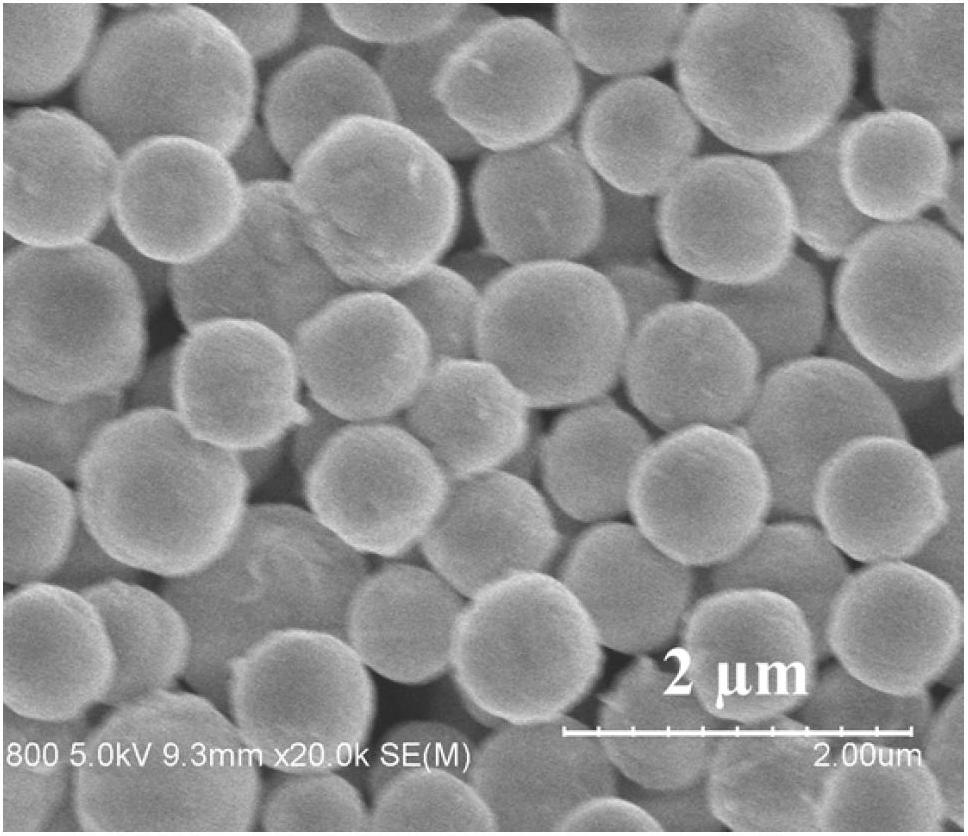

[0041] Standing and aging for 6 hours at a temperature of 80°C, a light green precipitate was obtained; the light green precipitate was filtered, washed, and dried to obtain a micronano-spherical nickel hydroxystannate precursor. The product characterization results are shown in the appendix figure 1 And attached figure 2 shown;

[0042] Micronano spherical nickel hydroxystannate precursor at 700 o C roasting for 2h, after natural cooling, light yellow porous micro-nano spherical NiO / SnO 2 Mixture powder, product characterization results are attached image 3 And attached Figure 4 sho...

Embodiment 2

[0044] Dissolve the tin tetrachloride pentahydrate raw material in water, adjust the pH value of the solution to 13.50 with 5.0M sodium hydroxide, prepare 30 milliliters of 0.5M sodium stannate solution, then add 4 milliliters of concentrated ammonia water (mass percentage concentration is 25.0 -28.0%), under magnetic stirring at a speed of 50 rpm, add 15 ml of 1.0M nickel sulfate solution to obtain a mixed solution;

[0045] Standing and aging at a temperature of 60°C for 6 hours, a light green precipitate was obtained; the light green precipitate was filtered, washed, and dried to obtain a micronano-spherical nickel hydroxystannate precursor;

[0046] The micro-nano spherical nickel hydroxystannate precursor was heated at 720 o C roasting for 2h, after natural cooling, light yellow porous micro-nano spherical NiO / SnO 2 Hybrid powder.

Embodiment 3

[0048] Dissolve the tin tetrachloride pentahydrate raw material in water, adjust the pH value of the solution to 11.80 with 5.0M sodium hydroxide, prepare 30 milliliters of 0.5M sodium stannate solution, then add 6 milliliters of concentrated ammonia water (mass percentage concentration is 25.0 -28.0%), under magnetic stirring with a rotating speed of 80 rpm, add 15 ml of 1.0M nickel sulfate solution to obtain a mixed solution;

[0049] Standing and aging at 60° C. for 8 hours, a light green precipitate was obtained. The light green precipitate is filtered, washed, and dried to obtain a micro-nano spherical nickel hydroxystannate precursor;

[0050] Micro-nano spherical nickel hydroxystannate precursor at 800 o C roasting for 2h, after natural cooling, light yellow porous micro-nano spherical NiO / SnO 2 Hybrid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com