Indoor aging method of rubber powder modified asphalt under joint effect of heat, oxygen and water

A technology for modifying asphalt and rubber powder, applied in the field of transportation engineering, can solve the problems of aggravated asphalt aging, changes in rainwater quality, affecting the long-term use function of asphalt, etc., and achieves the effect of improving the quality of the road surface and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

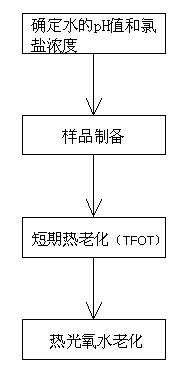

[0018] The indoor aging method of rubber powder modified asphalt under the combined action of hot oxygen water comprises the following steps:

[0019] (1) Determining the pH value and chlorine salt concentration of water: According to the actual precipitation in various regions of China, the average pH range of rainwater is determined to be 3.5-7.5, and the pH value is divided into five levels: 3.5, 4.5, 5.5, 6.5, 7.5; Combined with the chlorine salt content of seawater in various coastal areas and the use of deicing salt in northern regions, the mass concentration range of salt water is determined to be 0-3.5%, and the chlorine salt content is divided into 4 grades: 0, 1.5%, 2.5%, 3.5%, if it corresponds to the actual situation in a certain place, it is necessary to combine the rainwater with a certain level of PH value and the saline solution with a certain level of chlorine salt content for hot oxygen water aging;

[0020] (2) Sample preparation: Pour the melted rubber powd...

Embodiment 2

[0025] Indoor aging method of rubber powder modified asphalt under the combination of hot oxygen and water:

[0026] 1. Pour 50g of rubber powder-modified asphalt that has just been prepared or heated to a fluid state into a stainless steel flat-bottomed disc with a diameter of 140mm×9.5mm. The film thickness is about 3.2mm. Make four sample discs for each batch.

[0027] 2. Open the film oven, and after the oven reaches the test temperature of 163±1°C, quickly put 4 sample dishes on the turntable in the oven, close the oven door and start the turntable rack, so that the turntable is on the horizontal plane at a distance of 5.5±1r Rotate at a speed of 1 / min, the temperature in the oven rises to the test temperature and start timing, and the aging time is 5h.

[0028] 3. Determination of PH value and chlorine salt concentration of water. The water quality in various places is different, and the value of the pH value of rainwater is also correspondingly different, consults the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com