Seawater electromagnetic valve bank

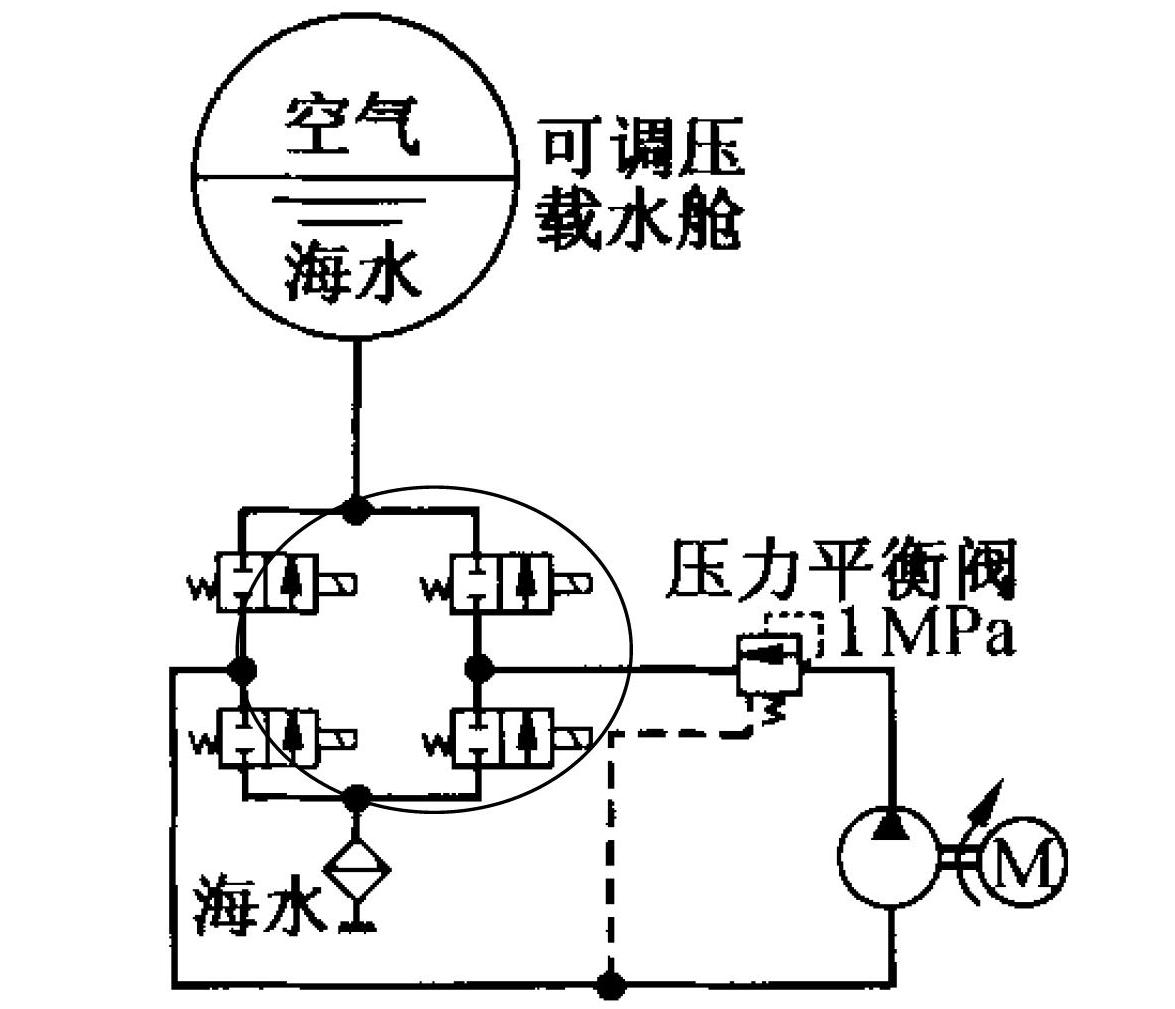

A technology of solenoid valve group and solenoid valve, which is applied in the direction of valve details, valve device, valve operation/release device, etc., which can solve the problem of reducing anti-pollution ability and reliability, lack of precision filtration of water quality, and increasing the difficulty of processing parts and other problems, to achieve the effect of compact structure, quick response, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

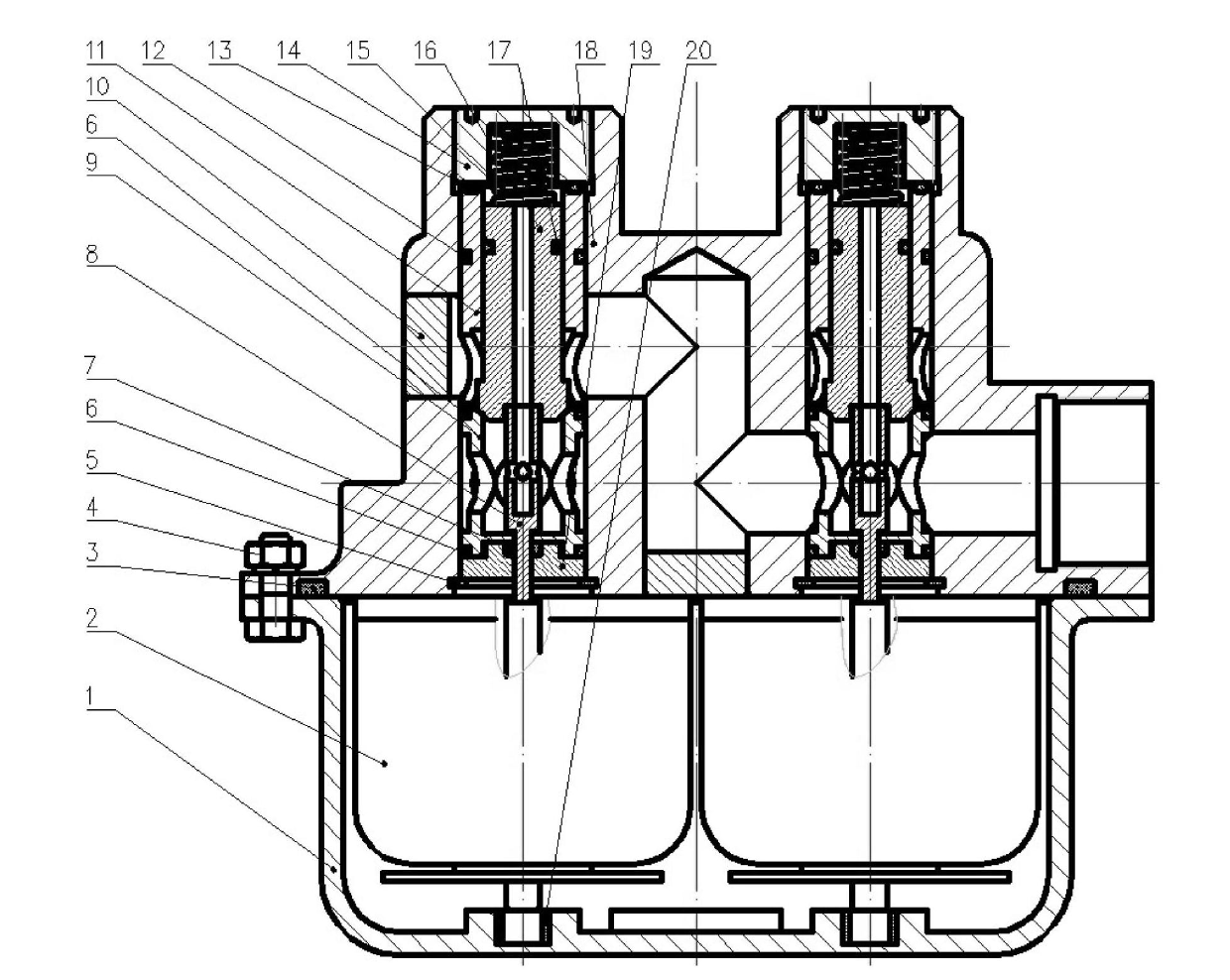

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

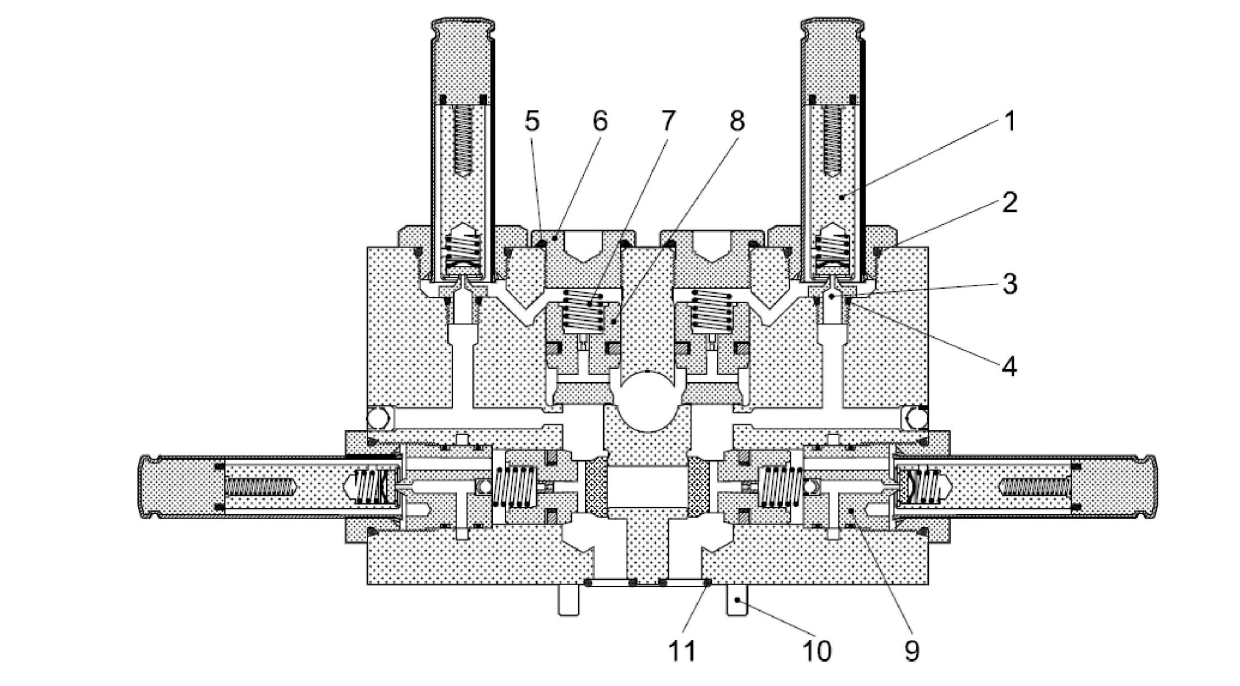

[0033] The seawater solenoid valve group in this embodiment is integrated by four independent solenoid valves. image 3 A schematic diagram of the internal structure of the solenoid valve group is given. Each solenoid valve includes a valve assembly, an electromagnet assembly 2 and a sealing cover 1 . Each solenoid valve body 18 is combined with the sealing cover 1 through 12 bolts, nuts, elastic washers and flat washers 4, and an O-ring 3 is added to realize sealing.

[0034] The valve assembly part of each solenoid valve includes a valve body 18, a screw plug 14, a spring 16, a valve core 15, a valve sleeve 11, a valve seat 9, a push rod 8, a valve sleeve seat 19, a retaining ring 5 and seals, electric- The mechanical conversion device includes a moving iron core 26, a pole shoe 22, a push rod 27, a rubber sleeve 25, a coil 24, a guide copper sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com