Automatic continuous-band freezing drier at vacuum low temperature

A vacuum low-temperature, continuous-belt technology, applied in dryers, drying solid materials, drying solid materials without heating, etc., can solve the problems of traditional Chinese medicines being susceptible to bacterial infection, backward production methods, and difficult to guarantee quality. The effects of controllability, high product quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

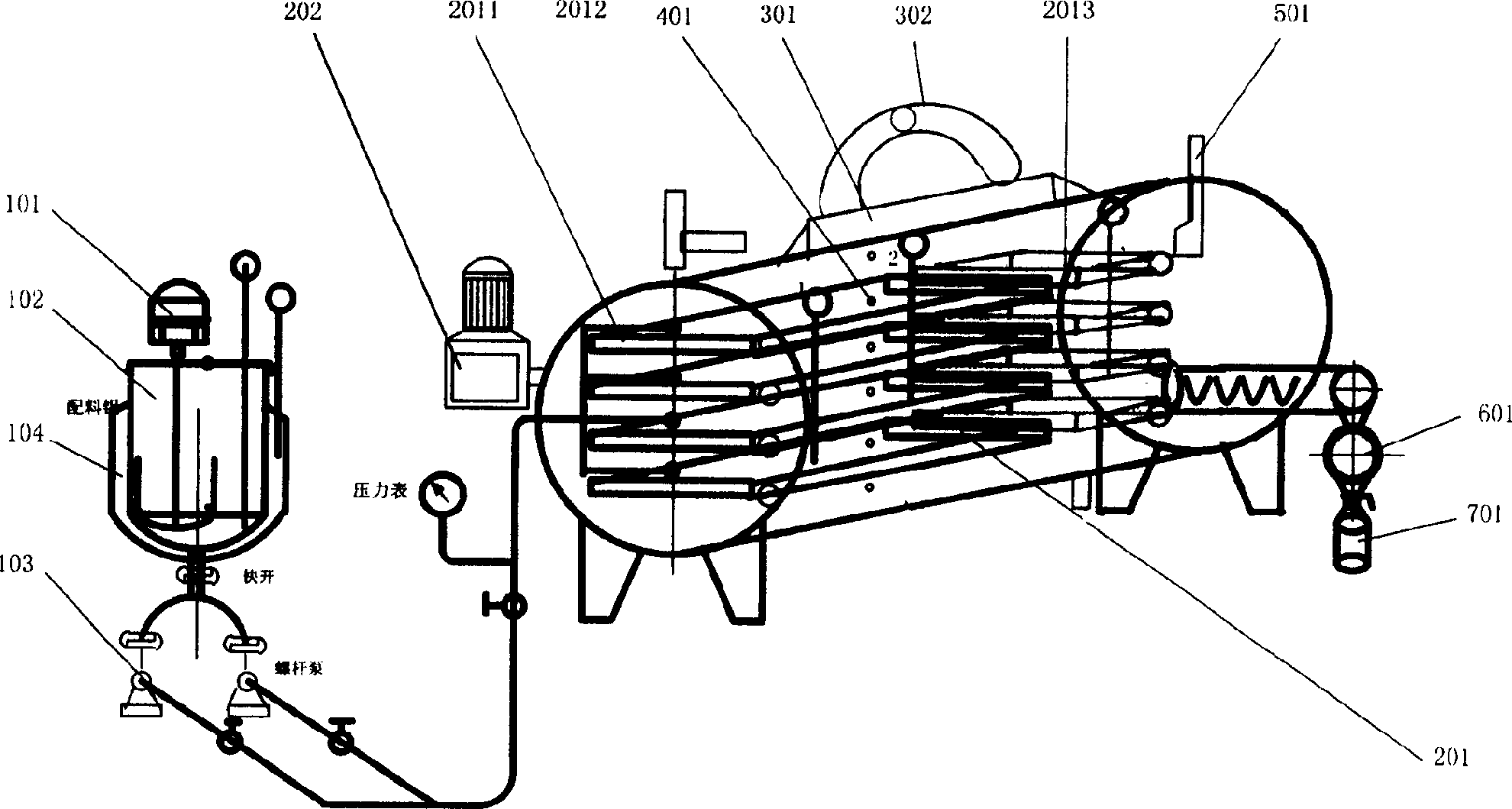

[0034] For the heat-sensitive material, it is first stirred in the batching mixer 101, and then sent to the batching pot 102, and the heat-sensitive material is heated by adjusting the temperature-regulating device 104 of the batching pot jacket to the heat treatment level, according to different process requirements , the heating temperature can be between 20 and 50°C; then the heat-sensitive material is sent to the drying belt drive by the single-screw 103 pump, and the heat-sensitive material is evenly spread on each layer of the drying belt at a certain speed through the distributor and the distribution nozzle 201, the uniform thin layer is generally 0.5 ~ 2mm thick, according to the properties of different heat-sensitive materials, adjust the drying belt drive motor 202 to adjust the translational speed of the drying belt 201; at this time, the vacuum degree in the drying belt drive -0.09Mpa (800pa~500pa), when the heat-sensitive material is conveyed to the upper part of t...

Embodiment 2

[0036]For the biological preparation, it is first stirred in the batching mixer 101, and then sent into the batching pot 102, and the biological preparation is frozen by adjusting the temperature adjustment device 104 of the batching pot jacket to the cooling treatment level, and the cooling temperature is 0~ Between -5°C; afterward, the single-screw 103 pump sends the biological preparation to the drying belt transmission device, and spreads the biological preparation evenly on the drying belt 201 that each layer moves at a certain speed through the distributor and the distributing nozzle. The uniform thin layer is generally 0.5-2mm thick, and the translational speed of the drying belt 201 can be adjusted by adjusting the drying belt drive motor 202 according to the properties of different biological agents; at this time, the vacuum degree in the drying belt drive device is -0.09Mpa (800pa ~500pa), when the biological agent is transported to the upper part of the temperature-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com