Solvent acrylic ester heat dissipation coating, and preparation method and application thereof

An acrylate and heat-dissipating paint technology, applied in lighting and heating equipment, coatings, cooling/heating devices for lighting devices, etc., can solve the problems of affecting heat dissipation effect, high cost, affecting heat dissipation effect, etc. and heat dissipation efficiency, high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

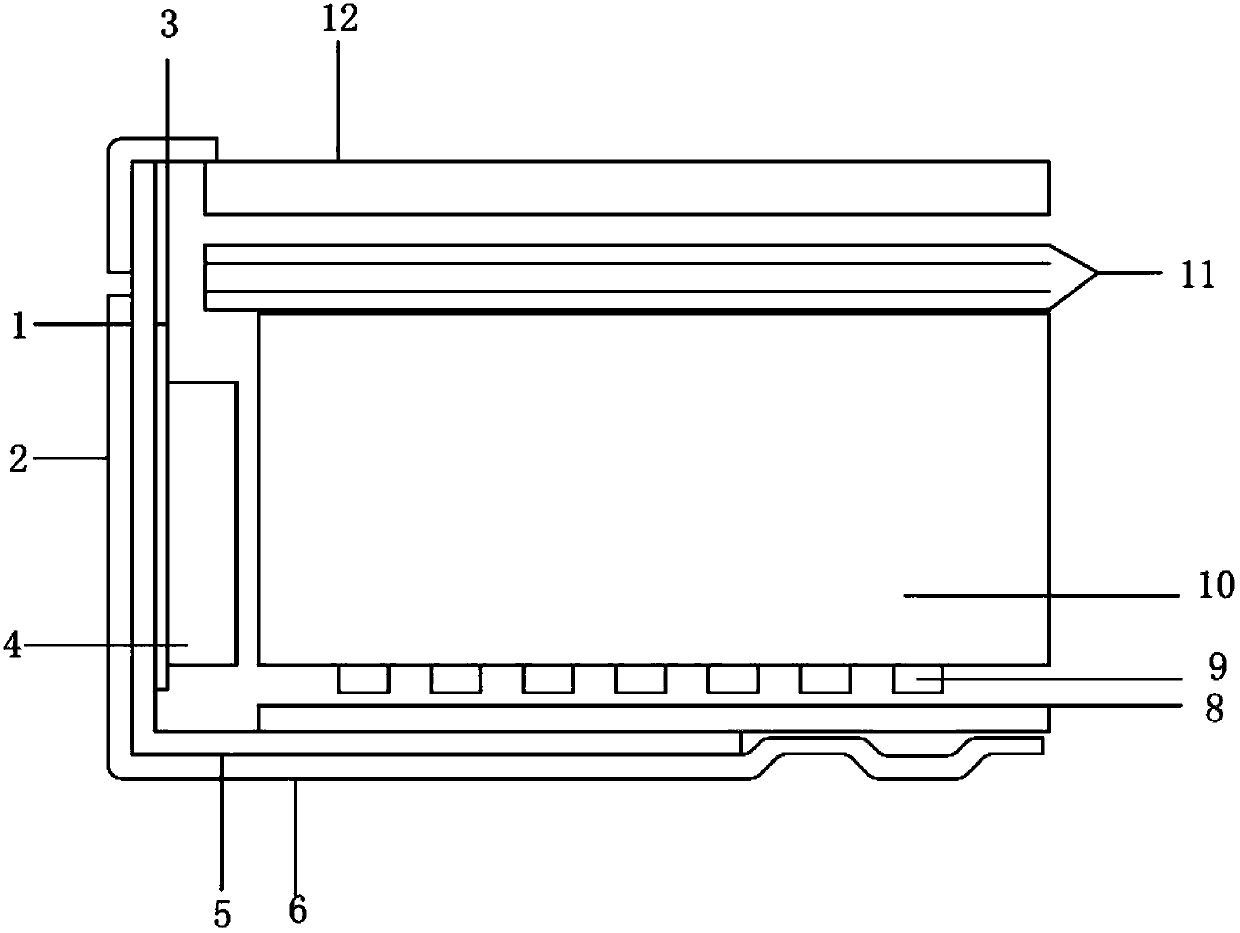

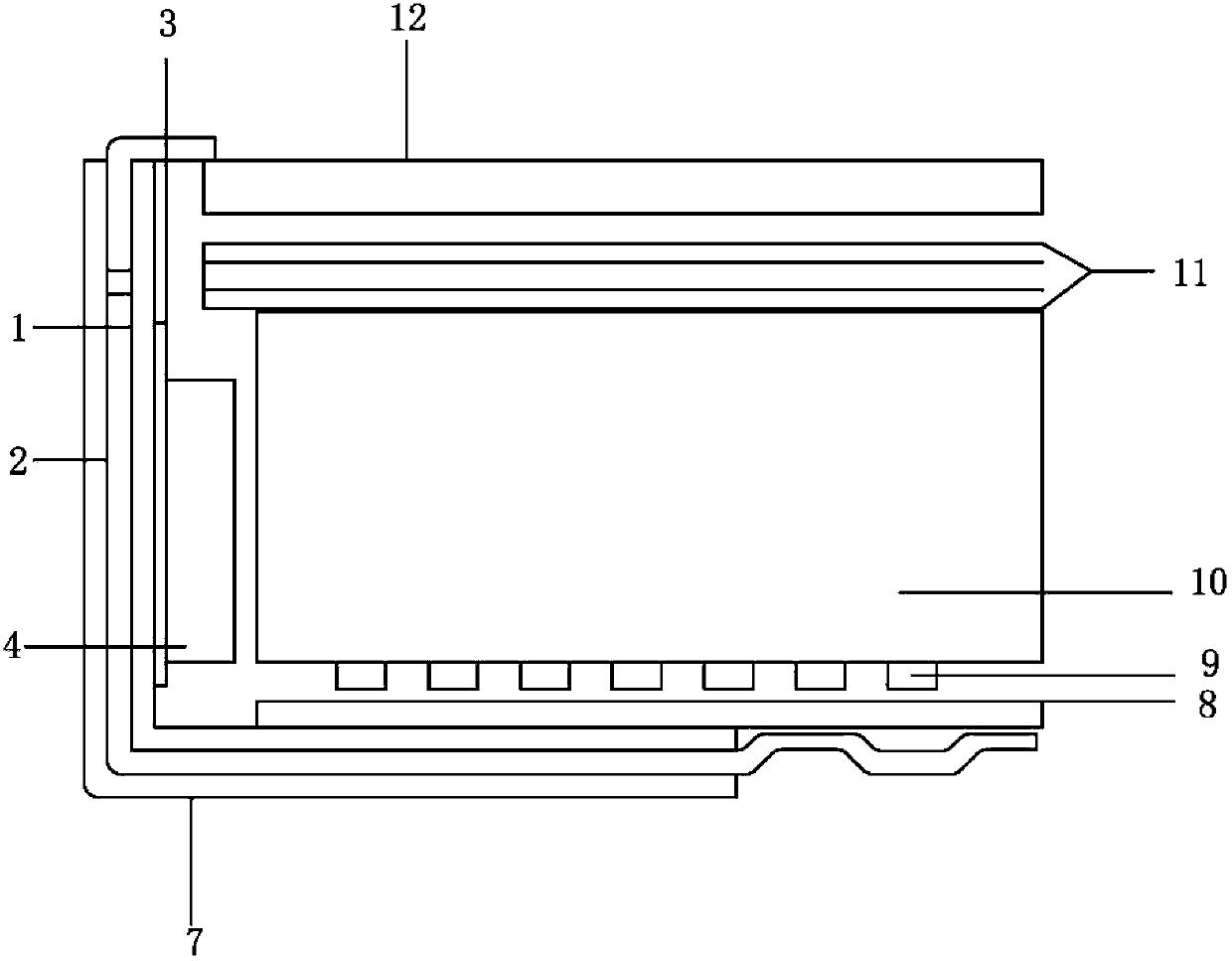

Image

Examples

Embodiment 1

[0058] 0.1g of azobisisobutyronitrile and 20g of butyl acetate were formulated as an initiator solution, and 3g of multi-walled carbon nanotubes (diameter 40nm, length 600nm) with a carboxyl content of 0.5% and 15g of carbon fibers (with a carboxyl content of 0.02% The pitch-based carbon fiber with a diameter of 7000nm and a length of 5000nm), 5g of styrene, 4.5g of acrylic acid, 65g of n-butyl acrylate, and 200g of butyl acetate were prepared into a monomer solution;

[0059] In the reactor with material mixing function and temperature control function, the temperature of the monomer solution was raised to 85°C, and the initiator solution was added dropwise to the monomer solution in 4 times to carry out the polymerization reaction. The time for each drop was 15 minutes. After the addition, the reaction was continued for 1 hour. When all the initiator solution was added to the polymerization system, the reaction was continued for 1 hour, and the synthesis reaction was complete...

Embodiment 2

[0065] 0.15g of azobisisobutyronitrile and 40g of ethyl acetate were prepared as an initiator solution, and 5g of hexagonal boron nitride (diameter 200-500nm) and 16g of carbon fiber (carboxylated pitch-based carbon fiber with a carboxyl content of 0.04% and a diameter of 7000nm , length 5000nm), 7.5g styrene, 5g methyl methacrylate, 80g 2-ethylhexyl acrylate, 220g ethyl acetate to prepare monomer solution;

[0066] In the reactor with material mixing function and temperature control function, the temperature of the monomer solution was raised to 75°C, and the initiator solution was added dropwise to the monomer solution in 4 times to carry out the polymerization reaction. The time for each drop was 15 minutes. After the addition, the reaction was continued for 1 hour. When all the initiator solution was added to the polymerization system, the reaction was continued for 1 hour, and the synthesis reaction was completed to obtain a coating solution.

[0067] Spray the coating so...

Embodiment 3

[0071] 0.1g of azobisisobutyronitrile and 20g of butyl acetate were formulated as an initiator solution, and 1.5g of multi-walled carbon nanotubes (diameter 40nm, length 600nm) with a carboxyl content of 0.7% and 13.5g of carbon fibers (a carboxyl content of 0.02 % carboxylated pitch-based carbon fiber, diameter 7000nm, length 5000nm), 9g styrene, 2g acrylic acid, 65g n-butyl acrylate, 20g acrylate-2-ethylhexyl, 280g ethyl acetate are mixed with monomer solution;

[0072] In the reactor with material mixing function and temperature control function, the temperature of the monomer solution is raised to 76 ° C, and the initiator solution is added dropwise to the monomer solution for polymerization reaction in 3 times, and the time of each drop is 15 minutes. After the addition, the reaction was continued for 1 hour. After all the thermal initiator solution was added to the polymerization system, the reaction was continued for 1 hour, and the synthesis reaction was completed to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com