Demulsifying slow breaking and quick setting modified emulsified asphalt by microwave heating and preparation method thereof

A slow-cracking, fast-setting, microwave heating technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of emulsified asphalt and stone can not be mixed evenly, poor storage stability, affecting project quality and other problems, and achieve excellent slow-cracking performance. , strong emulsifying ability, wide adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

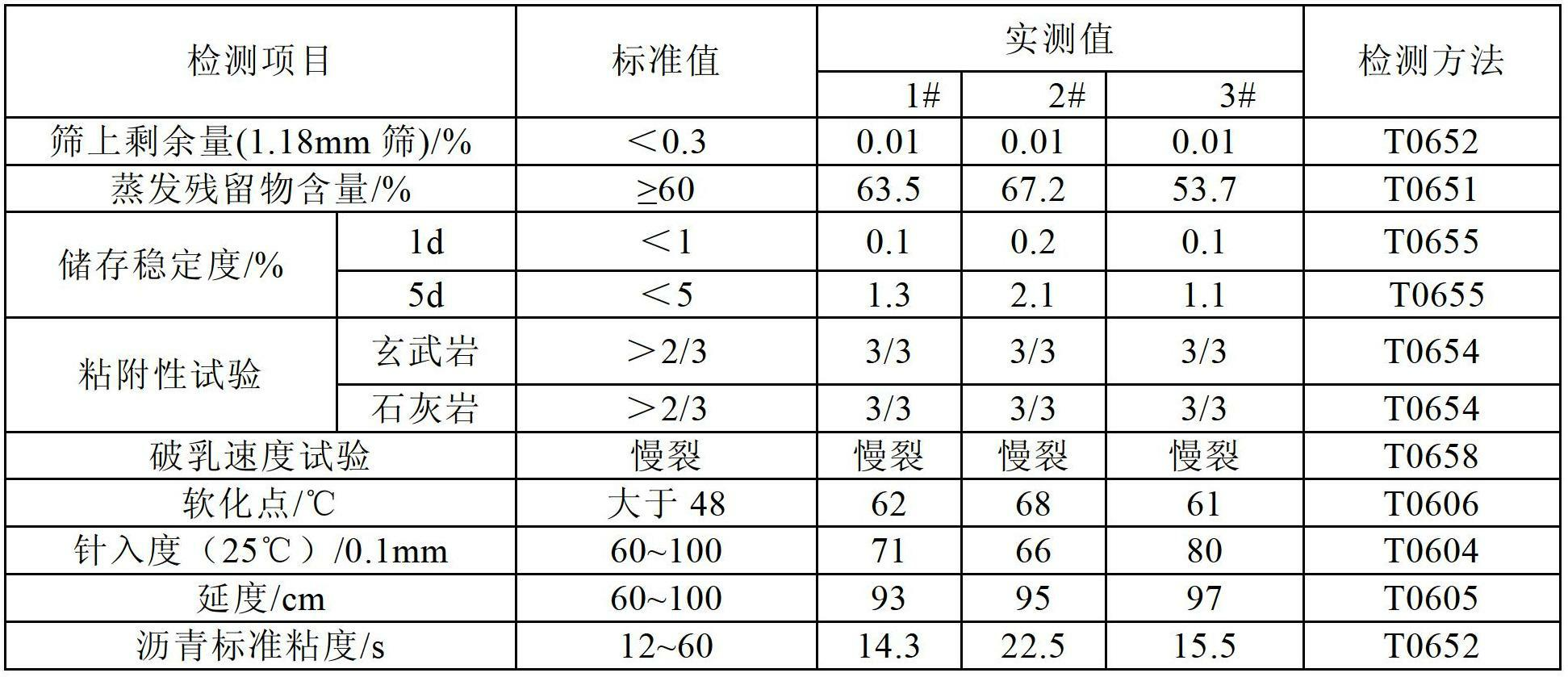

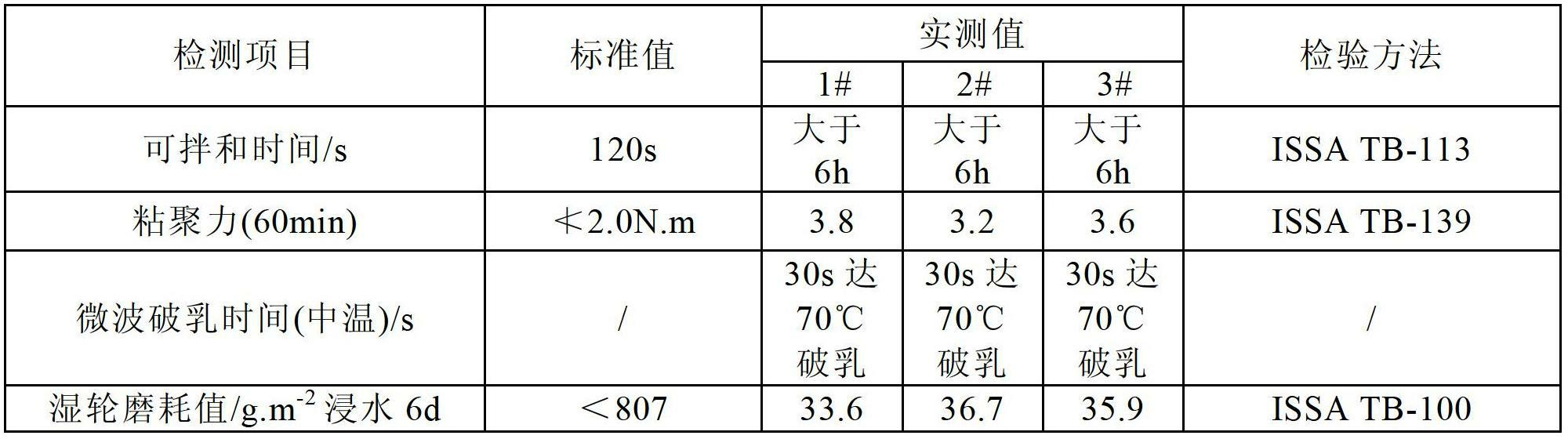

Embodiment 1

[0029] Heat 600g of Heavy Jiao No. 90 asphalt to 140°C and keep it warm for later use. Dissolve 10g of polyvinyl alcohol in 50g of water completely, pour 10g of sodium bentonite into polyvinyl alcohol aqueous solution to expand and age for 24 hours, and weigh 70g of WTW three Dissolve the compound compound emulsifier (the self-made ternary compound emulsifier contains about 21g of water) in 260°C water, then stir the prepared 70g compound stabilizer and WTW ternary compound emulsifier evenly, and heat the emulsifier aqueous solution to 60°C . The prepared base asphalt and emulsifier aqueous solution are added to the colloid mill at the same time as required, and the grinding can become the slow-cracking and fast-setting epoxy resin modified emulsified asphalt 1# for microwave heating and demulsification.

Embodiment 2

[0031] Heat 650g of Heavy Jiao No. 90 asphalt to 140°C and keep it warm for later use. Dissolve 10g of polyvinyl alcohol in 50g of water completely, pour 10g of sodium bentonite into the aqueous solution of polyvinyl alcohol to expand and age for 24 hours before use. Weigh 60g of MTM ternary compound emulsifier (the self-made ternary compound emulsifier contains about 18g of water) and dissolve it in 220g of water, then stir the prepared 70g of compound stabilizer and MTM ternary compound emulsion evenly, and heat the emulsifier The aqueous solution is brought to 60°C, and the prepared base asphalt and emulsifier aqueous solution are added to the colloid mill at the same time as required, and the grinding can become the slow-cracking and fast-setting epoxy resin modified emulsified asphalt 2# for microwave heating and demulsification.

Embodiment 3

[0033] Heat 550g of Heavy Jiao No. 90 asphalt to 140°C and keep it warm for later use. Dissolve 10g of polyvinyl alcohol in 50g of water completely, pour 10g of sodium bentonite into the aqueous solution of polyvinyl alcohol to expand and age for 24 hours before use. Weigh 80g of MTM ternary compound emulsifier (the self-made ternary compound emulsifier contains about 24g of water) and dissolve it in 300g of water, then stir the prepared 70g of compound stabilizer and MTM ternary compound emulsion evenly, and heat the emulsifier The aqueous solution is brought to 60°C, and the prepared base asphalt and emulsifier aqueous solution are added to the colloid mill at the same time as required, and the grinding can become the slow-cracking and fast-setting epoxy resin modified emulsified asphalt 3# for microwave heating and demulsification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com