Environment-friendly oil-resistant damping shock absorption and flame-retardant gasket material for motor unit train

A cushioning material and environment-friendly technology, which is applied in the fields of flame-retardant cushioning materials and environment-friendly oil-resistant damping and shock absorption, and can solve the problems of cushioning material burning, large deformation, and non-compliance with technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

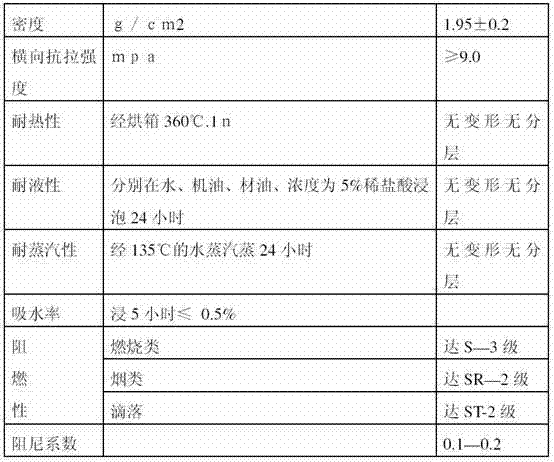

[0028] The composition of the gasket material and its weight percentage are as follows:

[0029] Fiber 18%

[0030] Rubber 14%

[0031] Filler 20%

[0032] Flame retardant 40%

[0033] Coupling agent 3%

[0034] Compounding agent 4%

[0035] Activator 1 %

[0036] The steps of the manufacturing process of the above-mentioned embodiment one gasket material are as follows:

[0037] Step 1, fiber pre-opening and mixing. First, aramid pulp fiber and glass fiber are added to the granulator in a weight ratio of 3:2 (ie 60% and 40%) for granulation and opening. After 30 After processing for a period of 1 minute to 1 hour, fluffy open fibers without agglomeration are obtained; then, add the open fibers together with fillers and flame retardants to a mixer and mix thoroughly to form a fiber-filled mixture . The above-mentioned fiber-filled mixture includes kaolin and calcium carbonate and is weighed and dosed in a weight ratio of 4:1.

[0038] Step 2, rubber plastic training p...

Embodiment 2

[0046] The composition of the gasket material and its weight percentage are as follows:

[0047] Fiber 11%

[0048] Rubber 12%

[0049] Filler 19%

[0050] Flame retardant 48%

[0051] Coupling agent 3.5%

[0052] Compounding agent 5%

[0053] Activator 1.5%

[0054] The manufacturing process steps of the gasket material of the above-mentioned embodiment 2 are the same as that of the embodiment 1, but as the content of fiber and rubber decreases relative to the embodiment 1, the transverse tensile strength decreases to nearly 9Mpa, and the processing manufacturability decreases.

Embodiment 3

[0056] The composition of the gasket material and its weight percentage are as follows:

[0057] Fiber 26%

[0058] Rubber 17%

[0059] Filler 15%

[0060] Flame retardant 32%

[0061] Coupling agent 2.2%

[0062] Compounding agent 6%

[0063] Activator 1.8%

[0064] The manufacturing process steps of the gasket material of the above-mentioned embodiment three are the same as those in the first embodiment, but with the increase of the rubber content, the heat resistance of the first embodiment decreases, and the reduction of the flame retardant content reduces the flame retardancy and the coupling agent The reduction of the product makes the compactness of the product insufficient, thus affecting the hardness and processing performance of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com