Continuous condensation process in production process of 2-vinylpyridine

A vinylpyridine and production process technology, applied in the field of continuous condensation technology, can solve the problems of many by-products, low yield, long reaction time, etc., reduce by-products, improve output and reaction yield, save electricity and steam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

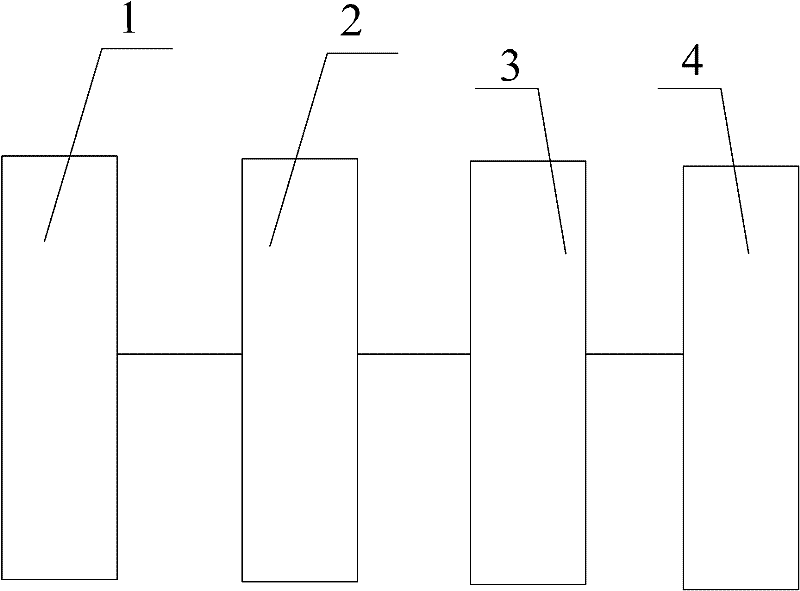

[0017] Use measuring tank 1 to prepare the mass ratio of 2-picoline and formaldehyde to be 5: 1, material temperature in batching tank 2 is 200°C, pressure is 3Mpa, feed rate is 150L / min, temperature of tubular preheater 3 is 260°C, pressure is 6Mpa. The temperature of the tubular reactor 4 is 240° C., and the pressure is 5 MPa. The discharge temperature was 245°C, and after 4 hours, it was detected that 2-vinylpyridine was 40%, 2-picoline was 58%, and high boilers were 0.4%. Hydroxyethyl production is 3.6 tons.

Embodiment 2

[0019] Use metering tank 1 to prepare the mass ratio of 2-picoline and formaldehyde to be 5:1, material temperature in batching tank 2 is 230°C, pressure is 5Mpa, feed rate is 150L / min, temperature of tubular preheater 3 is 280°C, pressure is 8Mpa. The temperature of the tubular reactor 4 is 260° C., and the pressure is 6 MPa. The discharge temperature was 247° C., detected after 4 hours, 2-vinylpyridine was 39%, 2-picoline was 59%, and high boilers were 0.5%. Hydroxyethyl production is 3.7 tons.

Embodiment 3

[0021] Use measuring tank 1 to prepare the mass ratio of 2-picoline and formaldehyde to be 5:1, material temperature in batching tank 2 is 250°C, pressure is 7Mpa, feed rate is 150L / min, temperature of tubular preheater 3 is 300°C, pressure is 9Mpa. The temperature of the tubular reactor 4 is 280° C., and the pressure is 7 MPa. The discharge temperature was 243° C., detected after 4 hours, 2-vinylpyridine was 41%, 2-picoline was 57%, and high boilers were 0.3%. Hydroxyethyl production is 3.6 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com