Process for synthesizing n-butyl acetate

A technology for the synthesis of n-butyl acetate, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

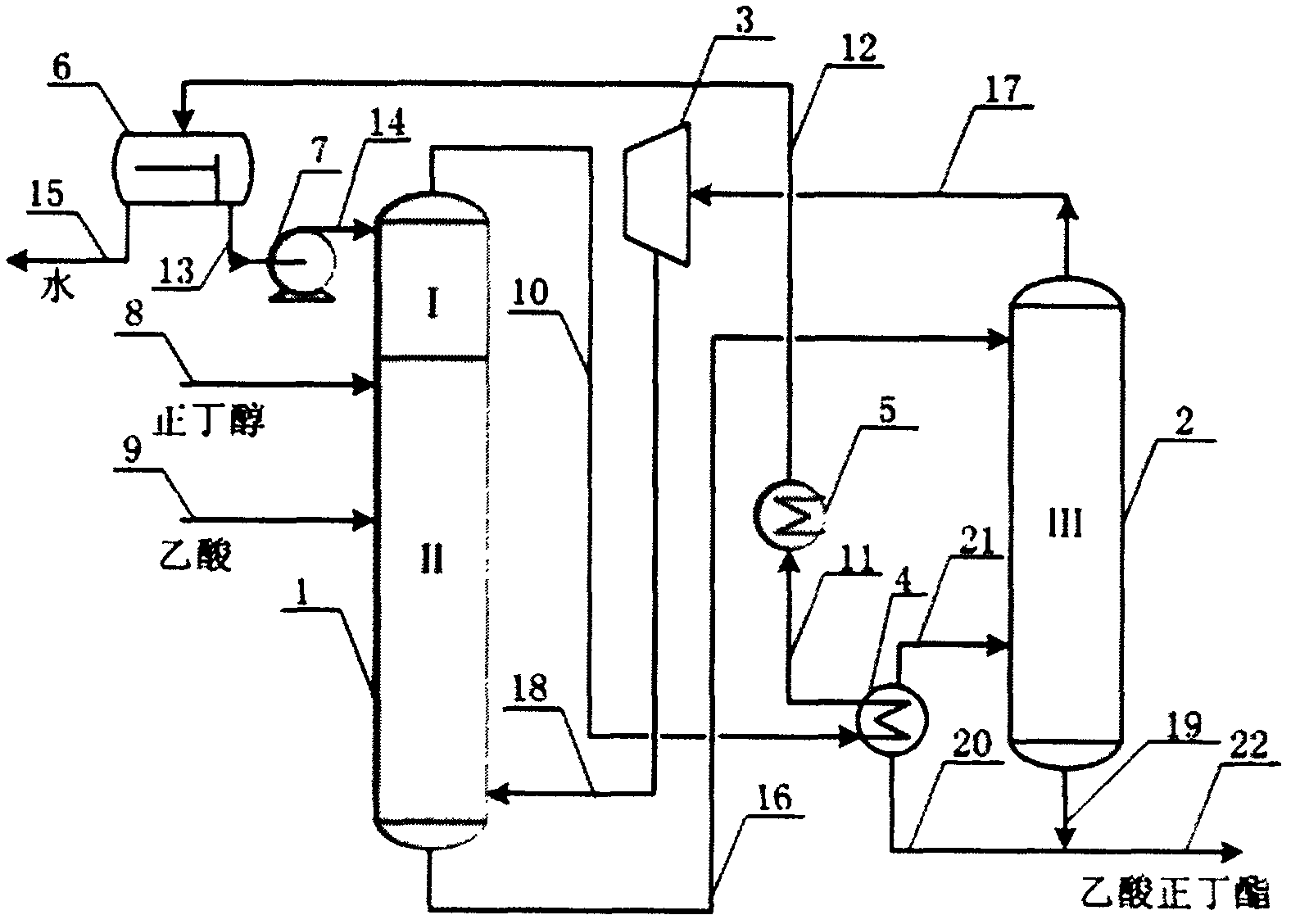

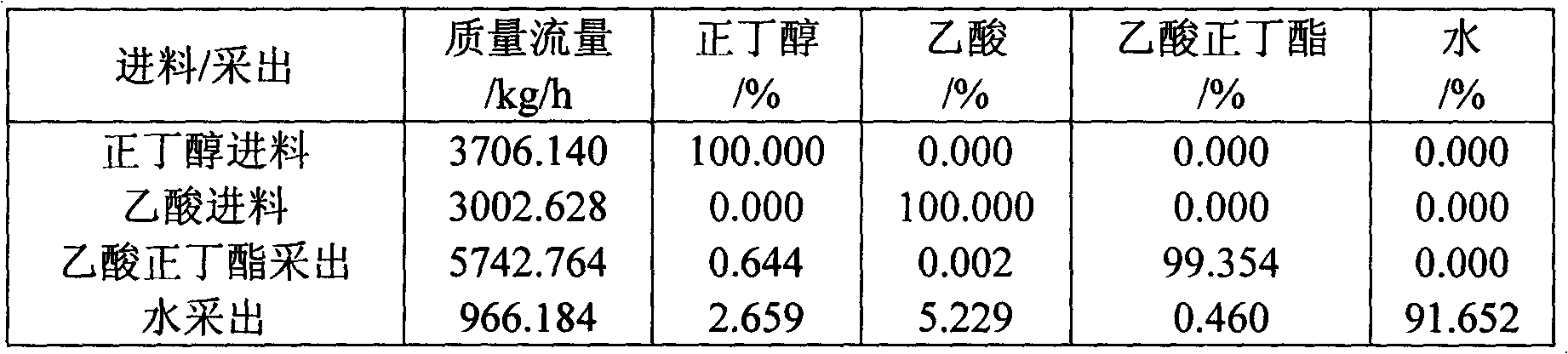

[0015] Embodiment 1: as figure 1 As shown, the number of theoretical plates in the differential pressure thermal coupling reaction distillation atmospheric column (1) rectification zone (|) is 5, the number of theoretical plates in the reaction zone (II) is 20, and the number of theoretical plates in the vacuum tower (2) is 10 , The feed n-butanol is fed from the 6th theoretical plate (counting from top to bottom) of the atmospheric column (1), and the acetic acid is fed from the 10th theoretical plate, and the feed molar ratio is 1:1. The flow rate and mass fraction of each incoming and outgoing stream are shown in Table 1. The temperature at the top of the atmospheric tower is 90.6°C, the temperature in the reaction zone is 91.6-116.6°C, the temperature of the phase separator is 50°C, and the temperature at the bottom of the vacuum tower is 78.0°C , The operating pressure of the vacuum tower is 0.02MPa. The acetic acid conversion rate is 98.39%. For the calculation of energ...

Embodiment 2

[0018] Embodiment 2: as figure 1 As shown, the feed composition, the molar ratio of feed n-butanol to acetic acid, the feed position and the number of theoretical plates in each area are the same as in Example 1, and the operating pressure of the decompression tower is 0.01MPa. The flow rate and mass fraction of each incoming and outgoing stream are shown in Table 2. The temperature at the top of the atmospheric tower is 91.1°C, the temperature in the reaction zone is 91.8-118.3°C, the temperature of the phase separator is 50°C, and the temperature at the bottom of the vacuum tower is 61.6°C . The acetic acid conversion rate is 97.93%. For the calculation of energy consumption, the same acetic acid conversion rate and product separation requirements are achieved. The heat load of the reboiler in the conventional reactive distillation process is 1925.663kW. The steam at the top of the pressure column provides the heat source, so only the energy consumption of the compressor is...

Embodiment 3

[0022] Embodiment 3: as figure 1 Shown, the mol ratio of feed composition, feed n-butanol and acetic acid and the number of theoretical plates in each area are the same as in Example 1, feed n-butanol and acetic acid enter the atmospheric tower from the 6th theoretical plate simultaneously, and the decompression tower operates The pressure is 0.03MPa. The flow rate and mass fraction of each incoming and outgoing stream are shown in Table 3. The temperature at the top of the atmospheric tower is 90.5°C, the temperature in the reaction zone is 92.5-116.1°C, the temperature of the phase separator is 50°C, and the temperature at the bottom of the vacuum tower is 83.2°C . The acetic acid conversion rate is 97.50%. For the calculation of energy consumption, the same acetic acid conversion rate and product separation requirements are achieved. The heat load of the reboiler in the conventional reactive distillation process is 1907.444kW. The steam at the top of the pressure column p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com