Washing bleaching and dyeing wastewater treatment method

A sewage treatment method, water washing technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increased difficulty in bleaching and dyeing wastewater treatment, large amount of chemical agents used, and incomplete Treat wastewater and other problems, achieve the effect of low sludge output, high reuse rate, and high load impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

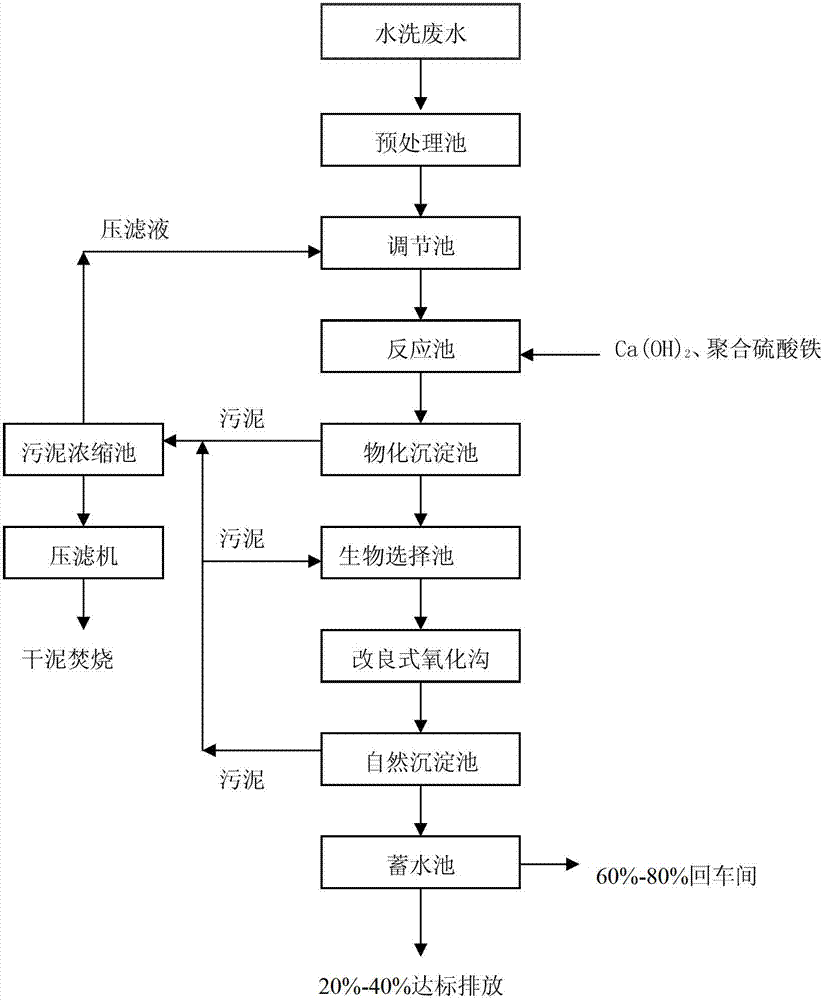

[0035] A washing, bleaching and dyeing factory in Yulin City, Guangxi is mainly engaged in the washing, bleaching and dyeing of garments and the production of crafts. The main pollutants in the wastewater include slurry, dyes, auxiliaries, surfactants, resins, fiber sundries, etc. Production wastewater has complex components, high pollution load, and is acidic. The daily discharge volume is 30,000 tons, COD600-1500mg / L, raw water BC ratio 0.3-0.45, and chromaticity 800-1200 times.

[0036]The washing, bleaching and dyeing sewage from each workshop is collected by the drainage ditches and flows into the grit chamber. After removing solid heavy objects such as sand and gravel, it enters the coarse and fine 2-stage grill pool. The grill pool is equipped with a mechanical grill machine, which automatically After removing ropes, cloth strips, fiber flocculation and other sundries, the sewage enters the regulating tank, and the regulating tank is equipped with a plug-flow agitator, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com