Continuous producing device and method of phosphorus pentafluoride

A technology for phosphorus pentafluoride and production equipment, applied in the direction of phosphorus halide/oxyhalide, etc., can solve the problems of inability to adapt to large-scale production of phosphorus pentafluoride, harsh reaction conditions, poor production continuity, etc., and achieves safe and reliable production process. control, good product quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

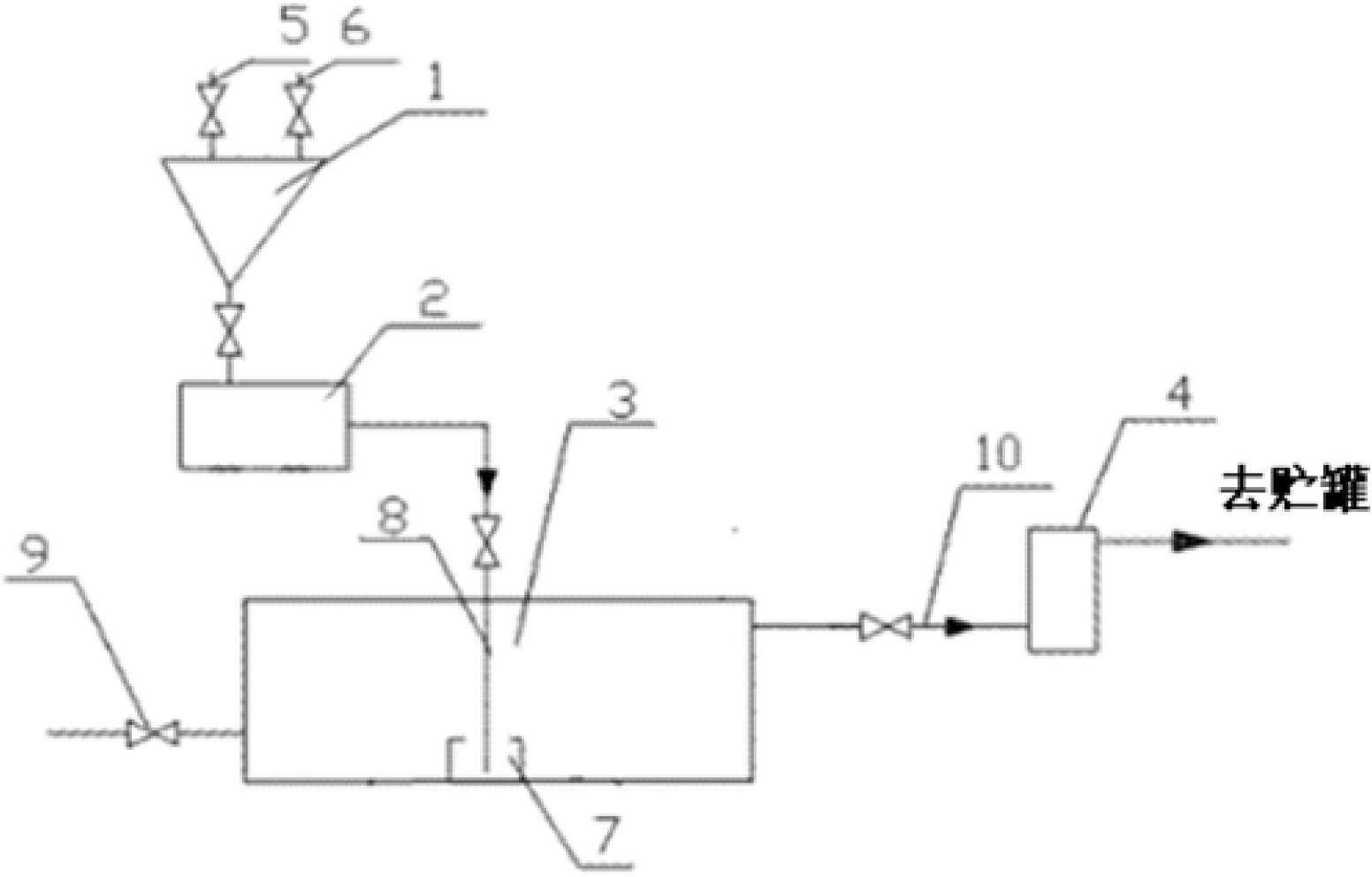

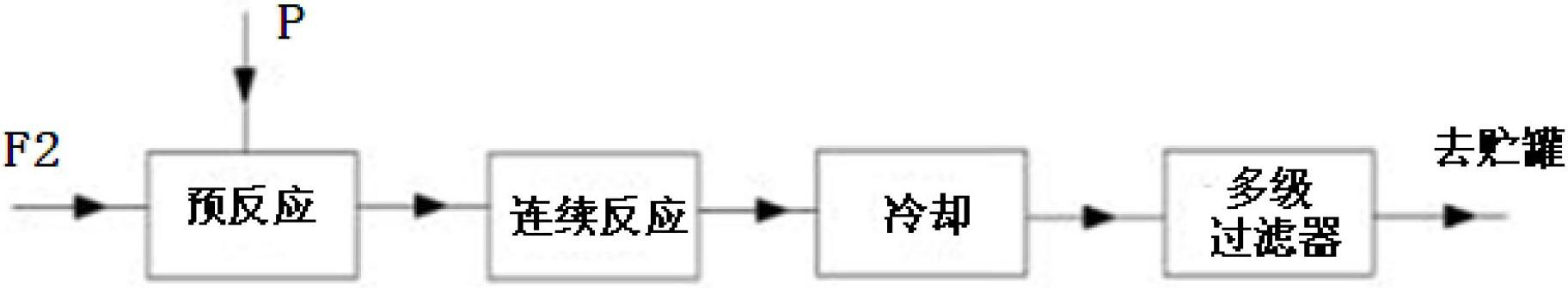

[0041] A continuous production device and process for phosphorus pentafluoride, comprising the following steps:

[0042] (1) Pre-reaction

[0043] First, add red phosphorus with a particle size of 5mm, a moisture content of less than 0.01%, and a purity of 99.5% into the 350L inverted conical pp material closed silo 1 of phosphorus element through the phosphorus element feed pipe 6, and then inject pressure through the inert gas interface 5 0.1MPa high-purity nitrogen protection, turn on the screw feeder 2, and slowly feed through the feeding insertion tube 8 to the pressure of -0.1MPa 1m 3Red phosphorus is added to the protection device 7 in the volumetric horizontal carbon steel material fluorophosphorus reactor 3. The protection device is a cylindrical protection device with an overflow opening at the upper end, until the elemental phosphorus overflows the protection device in the fluorophosphorus reactor 3. After installation 7, close the screw feeder 2.

[0044] Open th...

Embodiment 2

[0048] A continuous production device and process for phosphorus pentafluoride, comprising the following steps:

[0049] (1) Pre-reaction

[0050] First, add ground red phosphorus with a particle size of 0.2mm, moisture content of less than 0.01%, and a purity of 99.5% into the 350L inverted conical pp material closed silo 1 of phosphorus element through the phosphorus element feed pipe 6, and then pass through the inert gas The interface 5 is connected with high-purity nitrogen protection with a pressure of 0.1MPa, the screw feeder 2 is turned on, and the feeding insertion tube 8 is slowly fed into the 1m with a pressure of -0.1MPa. 3 Red phosphorus is added to the protection device 7 in the volumetric horizontal carbon steel material fluorophosphorus reactor 3. The protection device is a cylindrical protection device with an overflow opening on the upper end, until the phosphorus element overflows the protection device in the fluorophosphorus reactor. After 7, close the scr...

Embodiment 3

[0055] A continuous production device and process for phosphorus pentafluoride, comprising the following steps:

[0056] (1) Pre-reaction

[0057] First, add red phosphorus with a particle size of 0.5mm, a moisture content of less than 0.01%, and a purity of 99% into the 350L inverted conical pp material closed silo 1 through the phosphorus element feed pipe 6, and then feed it through the inert gas interface 5 Protected by high-purity argon gas with a pressure of 0.1MPa, turn on the screw feeder 2 and pass through the feeding insertion tube 8, slowly to the 1m with a pressure of -0.1MPa 3 Red phosphorus is added to the hemispherical protective device 7 with an upper opening in the volumetric horizontal carbon steel material fluorophosphorus reactor 3. The protective device is a hemispherical protective device with an overflow opening at the upper end until the elemental phosphorus overflows with fluorophosphorus. After the protection device 7 in the reactor, the screw feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com