Horizontal automatic wrapping machine for fishing rod

A technology for wrapping tape and fishing rod, which is applied in the field of automatic horizontal fishing rod wrapping machine, and achieves the effects of reasonable structure, improved tape spacing accuracy and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

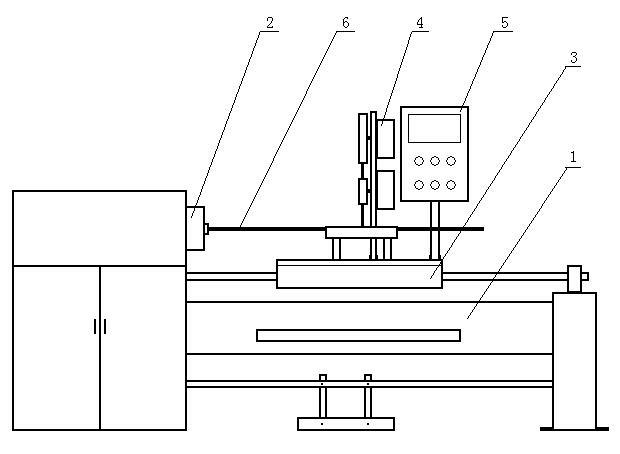

[0024] as attached figure 1 The overall structure schematic diagram of the present invention shown is a horizontal fishing rod automatic tape winding machine, including a frame 1, a chuck device 2, a tape transport device 3, a tape unwinding device 4, a controller 5, and a mandrel 6. The chuck device 2 is used to clamp the winding mandrel 6 and drive it to rotate to form a winding action; the tape running device 3 drags the tape releasing device 4 to travel, so that the tape material is wound on the mandrel 6 at a certain distance; The tape unwinding device 4 releases the tape material on the tape reel according to the tension set; the controller 5 is installed on the tape transport device 3 and walks with it.

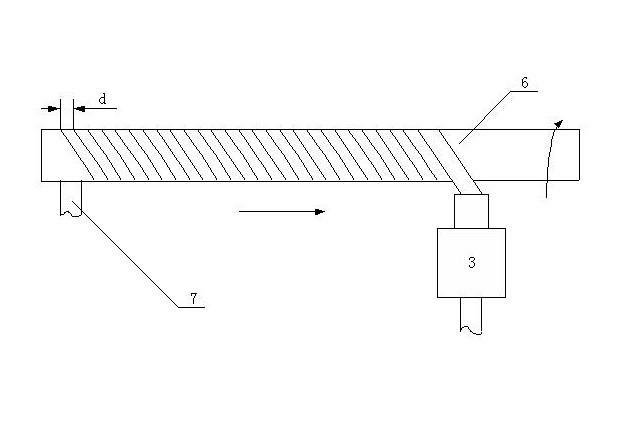

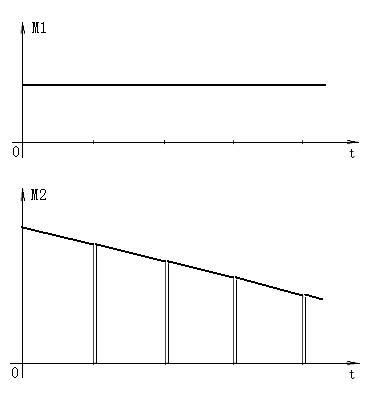

[0025] as attached figure 2 The principle of forming the tape distance shown is: while the mandrel 6 rotates at high speed to form a windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com