Multipurpose sharpening machine and tool setting plate for sharpening machine

A technology for grinding machines and cutting boards, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., which can solve the problems of high strength, high cost, and low efficiency, and reduce the operating intensity. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

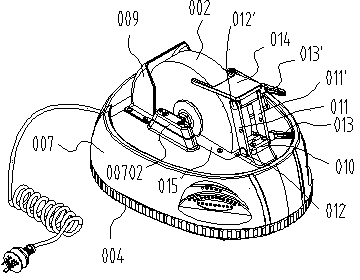

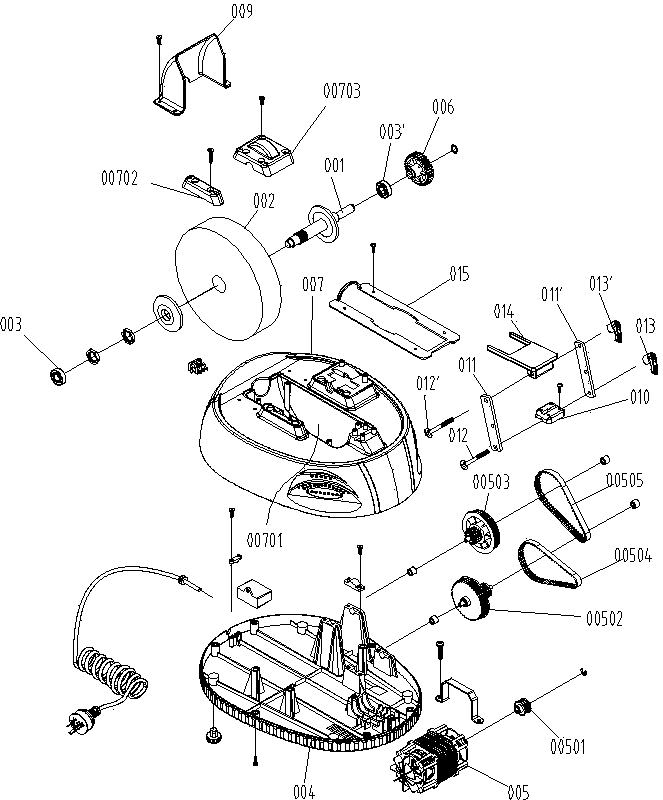

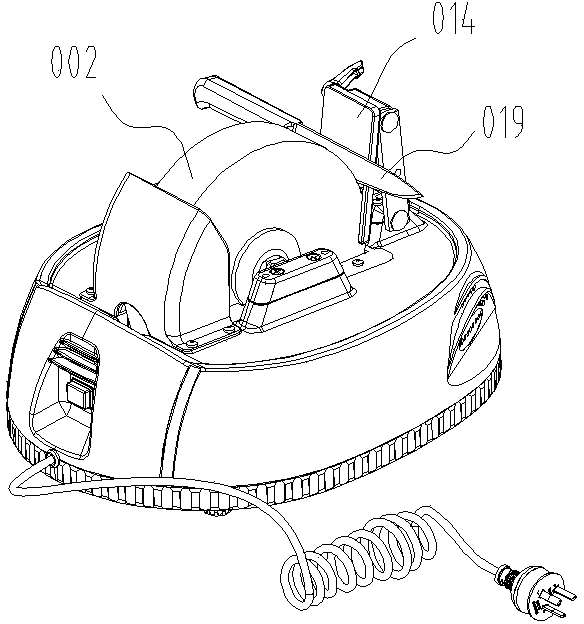

[0019] Such as Figures 1 to 3 As shown, a multi-purpose grinding machine of the present invention includes a base 004, a motor 005 disposed on the base 004, a grinding wheel 002 disposed on the grinding wheel shaft 001, a casing 007 covering the base 004, and a tool holder 014, the upper surface of the tool holder 014 is a plane, and its rear end is provided with a rectangular gap, the width of which is greater than the thickness of the grinding wheel 002; On the left and right bearing supports on the top of the casing 007, the casing 007 between the left and right bearing supports is recessed downwards to form a lower part of the grinding wheel 002 for holding water. Or the groove 00701 of the grinding fluid, there is a gap between the groove 00701 and the bottom of the grinding wheel 002 and the port of the groove 00701 is provided with a protective frame 015; The gear 006 is connected by transmission. The transmission mechanism includes a small pulley 00501, a first trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com