Preparation methods of layered titanium matrix composite material

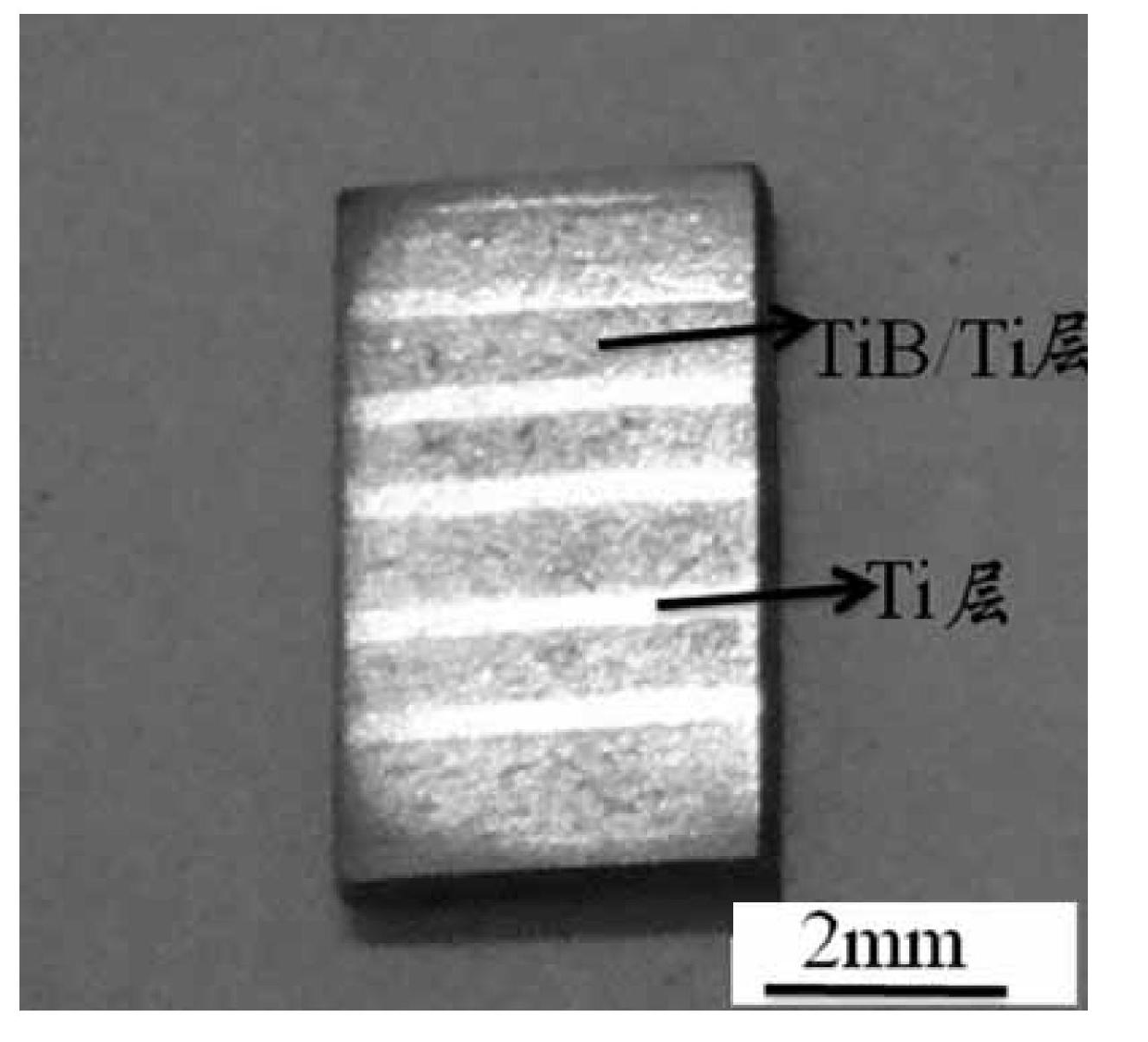

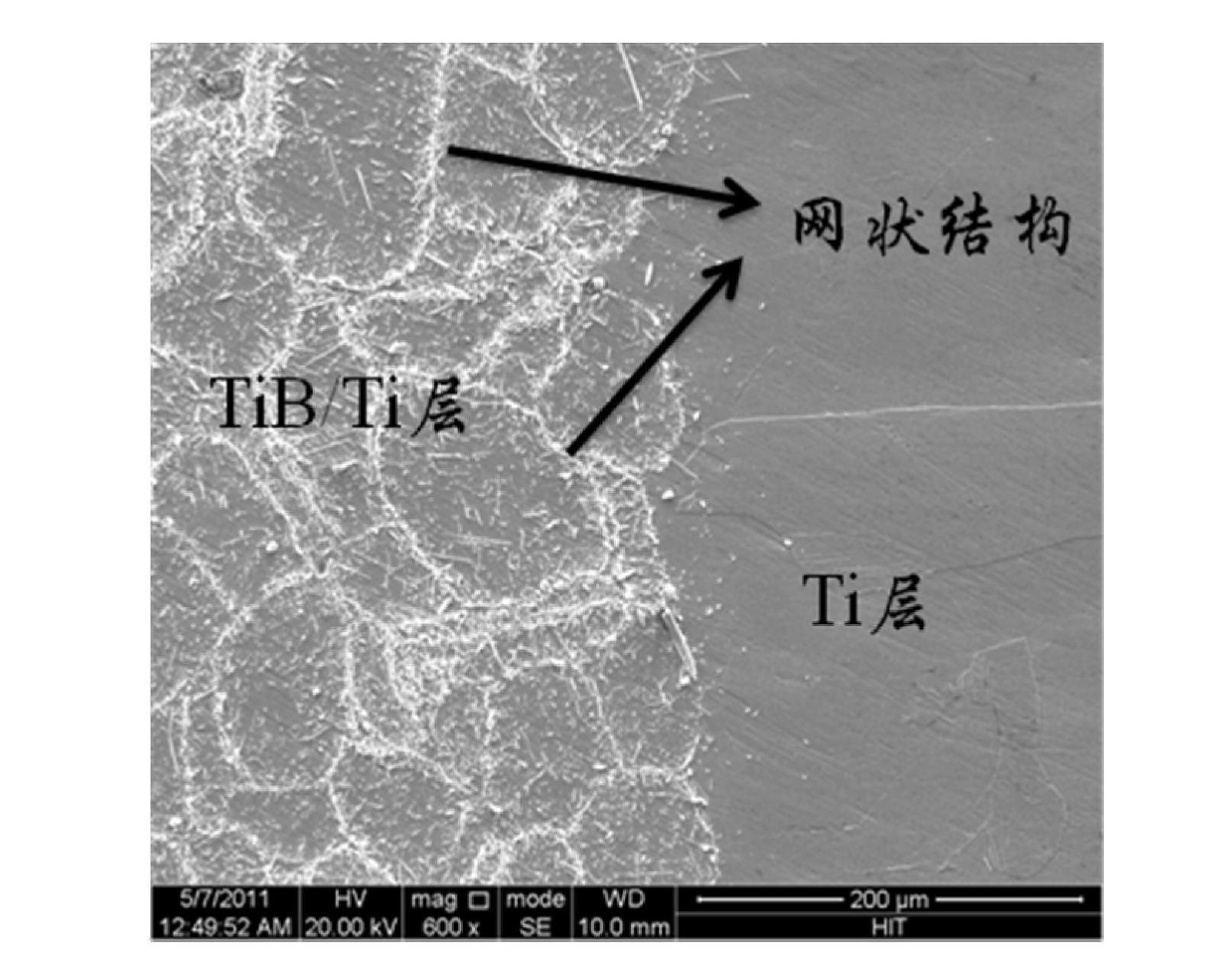

A titanium-based composite material and layered technology is applied in the field of preparation of titanium-based composite materials, which can solve the problems of poor plasticity of layered titanium-based composite materials, achieve good delayed fracture, improve uniform plastic deformation, and avoid oxidation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: The preparation method of the layered titanium-based composite material of this embodiment is carried out according to the following steps:

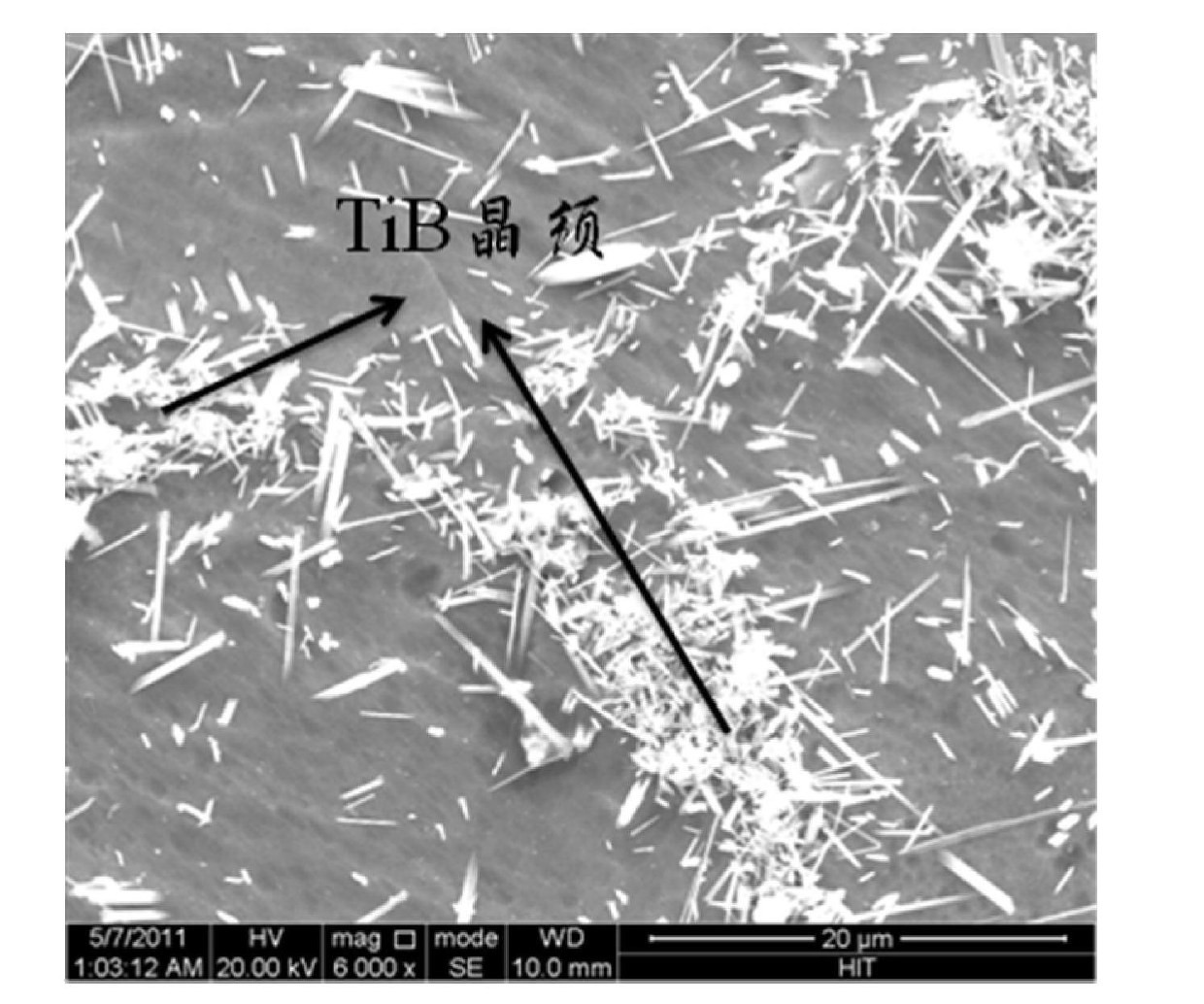

[0024] 1. Preparation of mixed powder: Weigh 85% to 97% of Ti particles with a particle size of 80 to 200 μm and 3% to 15% of TiB with a particle size of 3 to 10 μm by volume percentage 2 The powder is added into a planetary ball mill, the mass ratio of the ball to material is 4-5:1, and the ball mills for 4-12 hours under the condition of a rotating speed of 100-250 rpm to obtain a mixed powder;

[0025] The purpose of the low-energy ball milling in this step is to make TiB 2 The powder evenly adheres to the surface of the spherical Ti particles, and can ensure that the Ti particles will not be broken.

[0026] Two, the preparation of powder paste: according to the mass ratio of polyethanol solution and mixed powder is 1: 20~25, weigh polyethanol solution and the mixed powder prepared in step 1 and stir evenly, obt...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 90% to 95% of Ti particles with a particle size of 90 to 180 μm and 5% to 10% of Ti particles with a particle size of 5 to 10 μm are weighed by volume percentage 8 μm TiB 2 The powder is added into a planetary ball mill, the mass ratio of the ball to material is 4.2-4.8:1, and the ball mills for 6-10 hours under the condition of a rotating speed of 150-200 rpm to obtain a mixed powder. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of the polyethanol solution to the mixed powder in step 2 is 1:22-24. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com