Separated air drum of electric air-assisted spraying machine

A sprayer and motor technology, applied in the direction of the spraying device, can solve the problems of reducing the flexibility of the air cylinder, increasing the spraying distance, and bulky devices, so as to improve the utilization rate and ventilation efficiency, increase the spraying distance, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

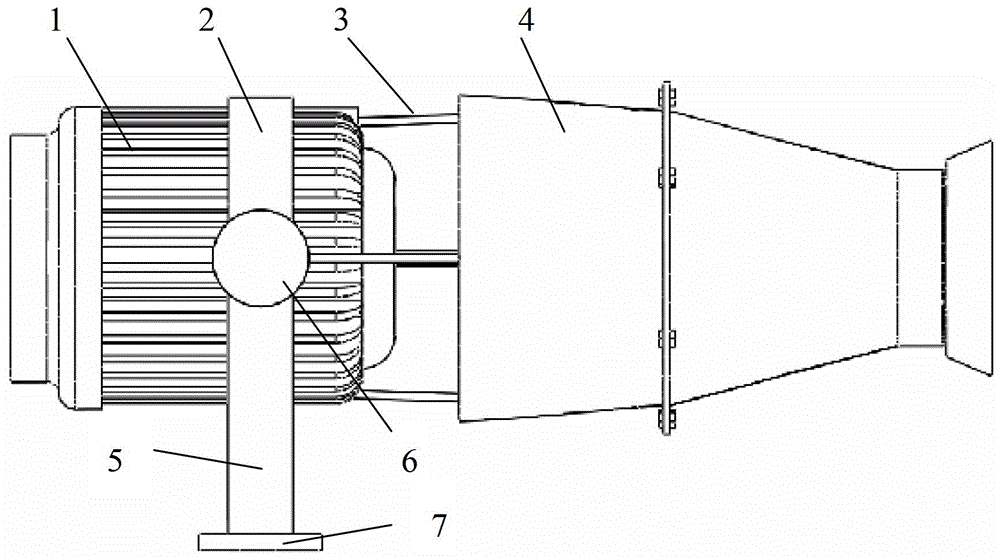

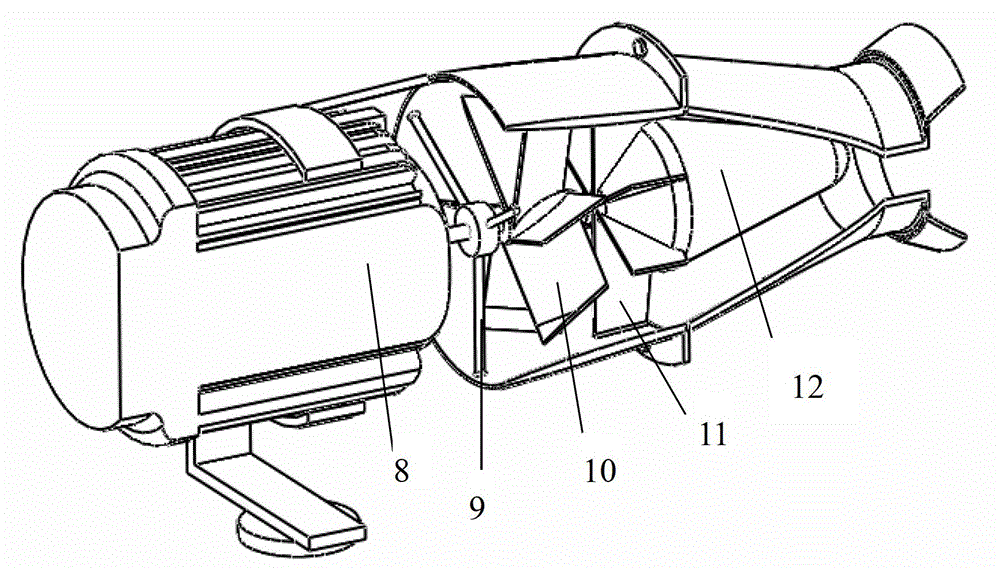

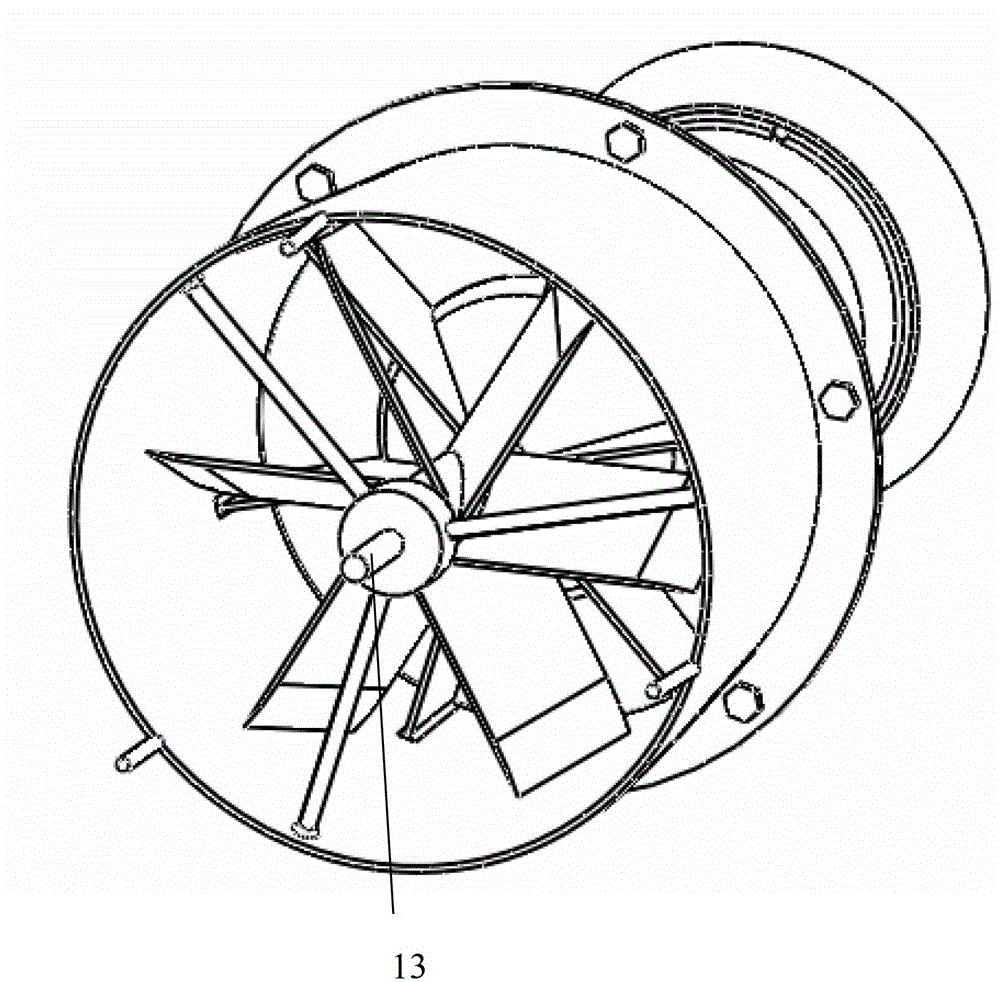

[0029] Such as figure 1 , 2 As shown in and 3, a discrete air duct of an electric air blower sprayer includes an electric motor 1, an air duct housing 4 and a fan blade 10; the electric motor 1 and the air duct housing 4 are arranged separately, and the motor 1 is connected to the air duct housing 4 through the connecting piece 3, the rotating shaft of the motor 1 is connected to the fan blade 10, and the fan blade 10 is installed inside the air duct housing 4. Through the separate arrangement of the motor and the air duct shell, the effective area of the air duct air inlet is increased, and the space utilization rate and ventilation efficiency of the air duct are improved.

[0030] An air gap of a certain width is provided between the electric motor 1 and the air duct air inlet. This setting improves the flow of air at the air inlet.

[0031] The width of the air gap is adjustable, and the range of the width adjustment is 20 cm to 30 cm.

[0032] A mounting frame is included. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com