Preparation method of CuOx/CeO2 catalyst with high CO-PROX activity

A catalyst and active technology, which is applied in the field of preparation of CuOx/CeO2 catalyst, can solve the problems that have not yet been seen, and achieve the effects of avoiding the loss of active species, high catalytic activity at low temperature and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. CuCe-200

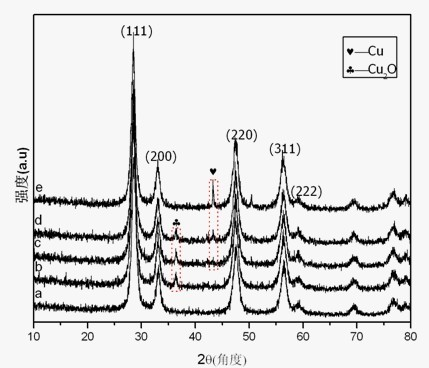

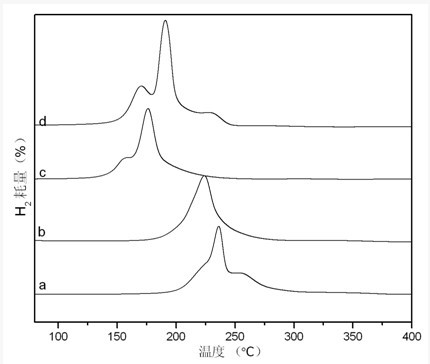

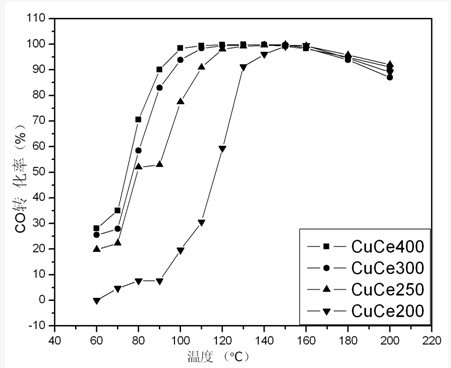

[0024] Accurately weigh 0.4046g copper acetate monohydrate and 2.000g CeO 2 , mixed in a mortar, and uniformly ground for 30 minutes until the copper acetate and the carrier CeO 2 Mix well and evenly, dry in a vacuum desiccator at 60°C for 12h, in a tube furnace, N 2 The flow rate is 100ml / min, the heating rate is 5°C / min, the temperature rises to 200°C, N 2 The CuCe-200 sample was calcined under the atmosphere for 3h, and the Cu content was 6wt%. The wide-angle XRD result, H 2 -TPR, CO-PROX reactivity and selectivity as attached Figure 1-4 shown.

Embodiment 2

[0025] Example 2. CuCe-250

[0026] Accurately weigh 0.4046g copper acetate monohydrate and 2.000g CeO 2 , mixed in a mortar, and uniformly ground for 30 minutes until the copper acetate and the carrier CeO 2 Mix well and evenly, dry in a vacuum desiccator at 60°C for 12h, in a tube furnace, N 2 The flow rate is 100ml / min, the heating rate is 5°C / min, the temperature is raised to 250°C, and the temperature is kept at N 2 The CuCe-250 sample was calcined under the atmosphere for 3h, wherein the Cu content was 6wt%, and its wide-angle XRD result, H 2 -TPR, CO-PROX reactivity and selectivity as attached Figure 1-4 shown.

Embodiment 3

[0027] Example 3. CuCe-300

[0028] Accurately weigh 0.4046g copper acetate monohydrate and 2.000g CeO 2 , mixed in a mortar, and uniformly ground for 30 minutes until the copper acetate and the carrier CeO 2 Mix well and evenly, dry in a vacuum desiccator at 60°C for 12h, in a tube furnace, N 2 The flow rate is 100ml / min, the heating rate is 5°C / min, the temperature is raised to 300°C, and the temperature is kept at N 2 The CuCe-300 sample was calcined under the atmosphere for 3h, and the Cu content was 6wt%. The wide-angle XRD result, H 2 -TPR, CO-PROX reactivity and selectivity as attached Figure 1-4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com