Radioactive anion resin microsphere and preparation method (1) thereof

An anion resin and weakly basic anion technology, applied in the direction of radioactive carriers, radioactive physical shapes, etc., can solve the problems of relying on reactors, high density of glass microspheres, and high purity requirements of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

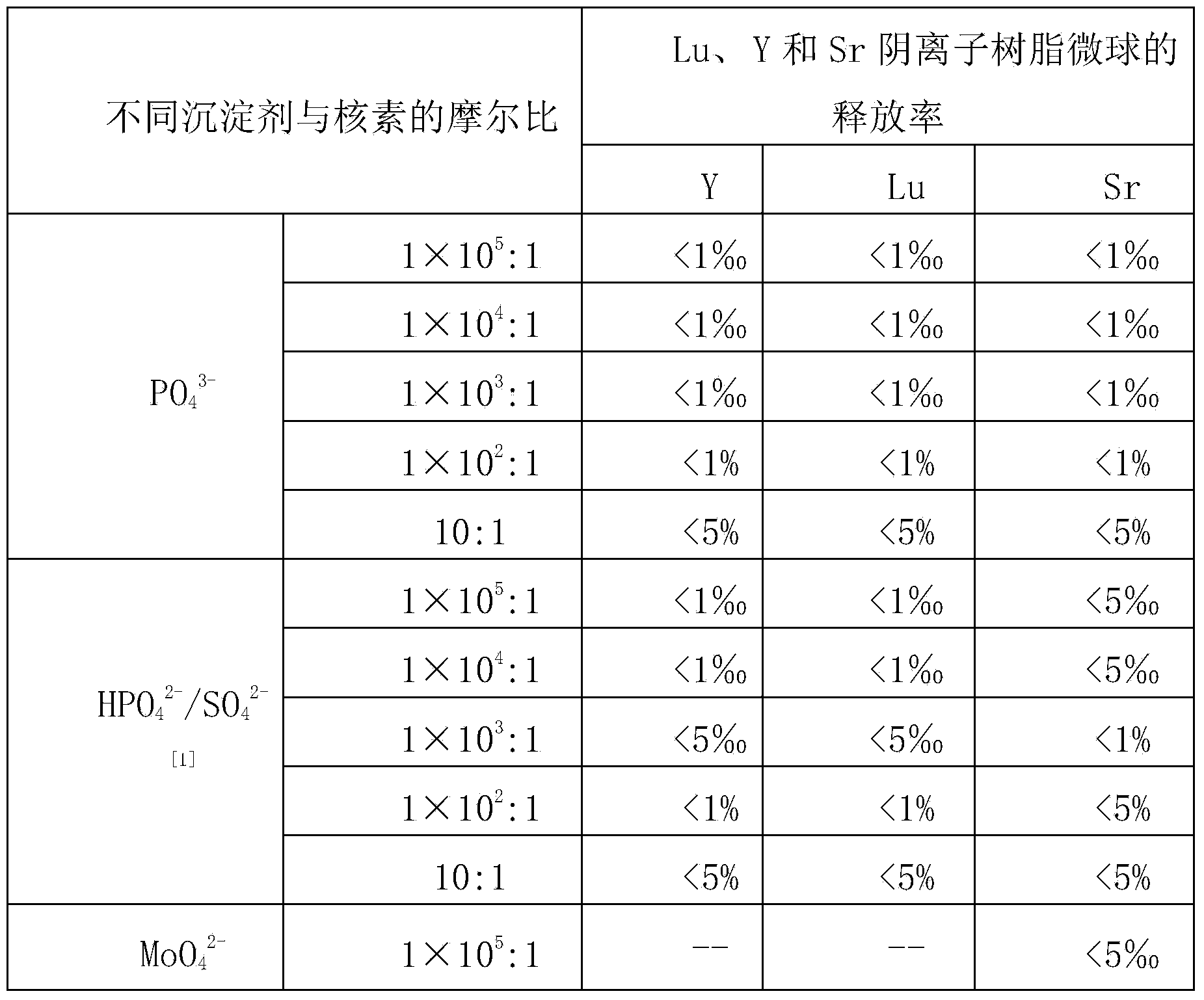

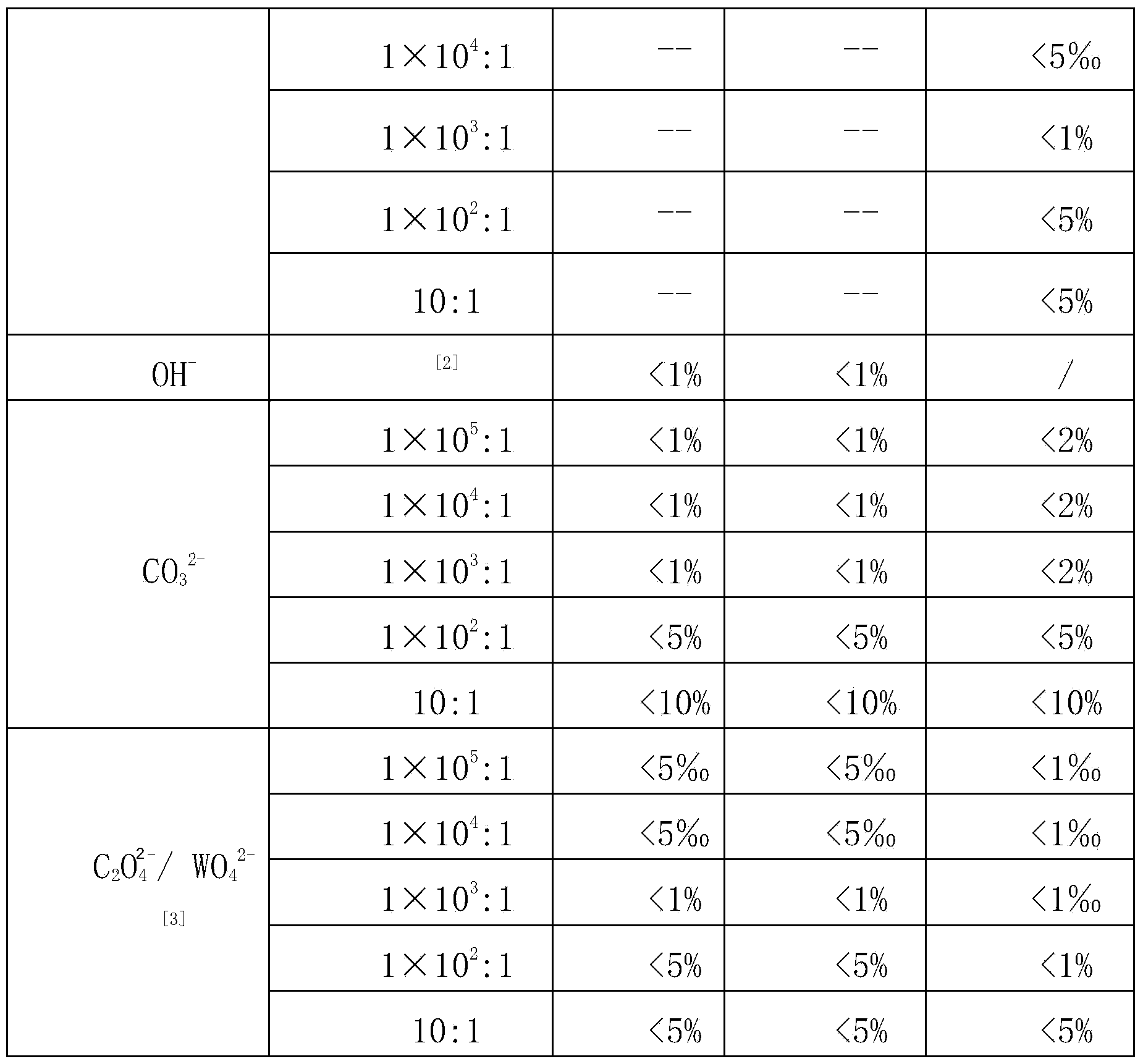

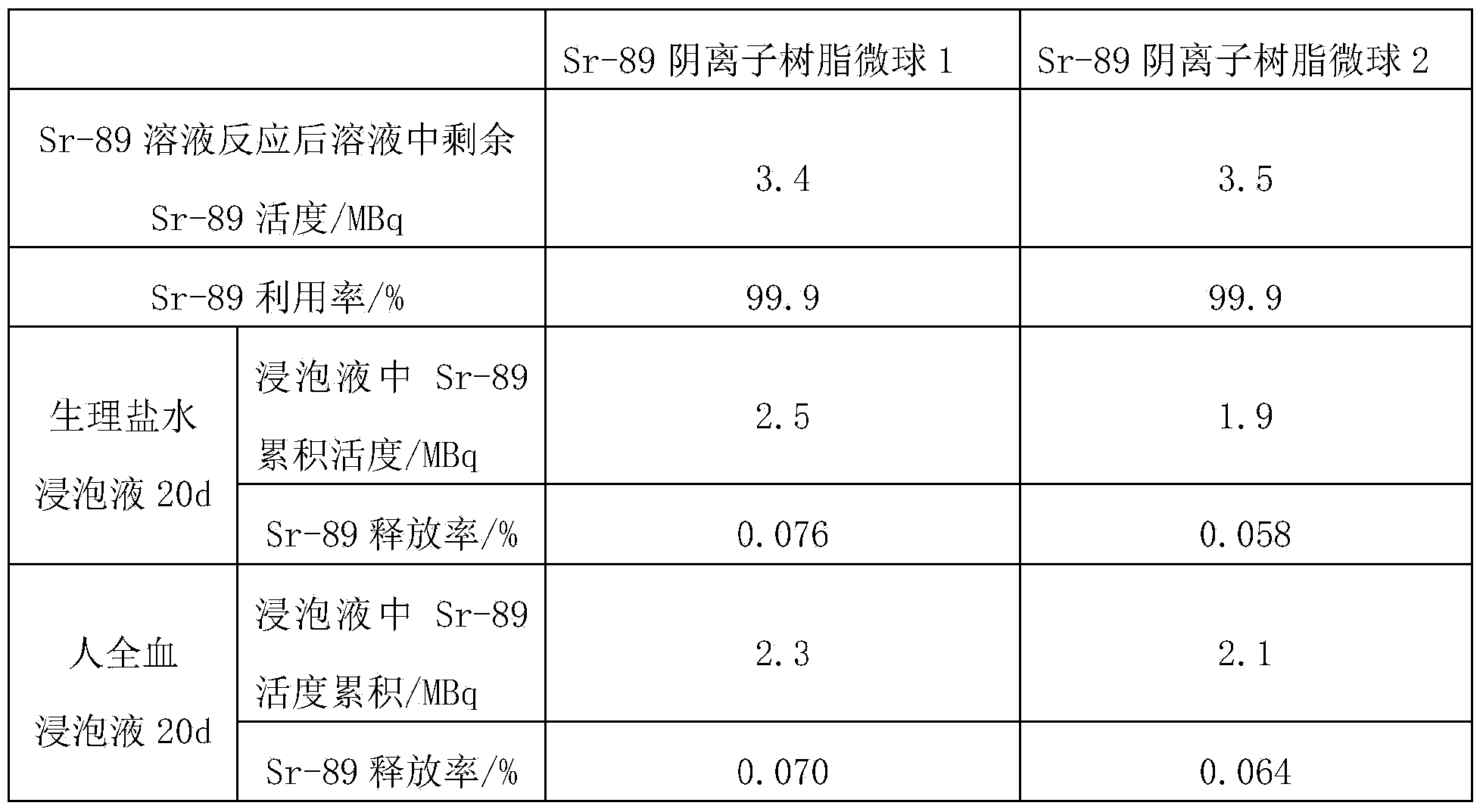

[0053] Embodiment 1-2: Sr-89 anion resin microspheres.

[0054] The anionic resin microspheres listed in embodiment 1 and embodiment 2 include the styrene-divinylbenzene anion exchange resin (201 × 7 resin) with a cross-linking degree of 7% and a diameter of 20 μm to 40 μm, and are solidified in the form of precipitation on The Sr-89 anion resin microsphere inside the 201×7 resin anion resin.

Embodiment 1

[0056] (1) 1g of styrene-divinylbenzene anion exchange resin (201×7 resin) with a cross-linking degree of 7% and a diameter of 20 μm to 40 μm is transformed into an OH-type strong alkalinity;

[0057] (2) Place the anion resin obtained in step (1) under room temperature conditions in 20mL, and the mass percent concentration that the pH value is 11 is 3% Na 3 PO 4 Soaked in the solution for 30min, the PO 4 3- Exchange to the inside of the anion resin obtained in step (1); wash with water until the pH value of the cleaning solution is less than 8;

[0058] (3) The adsorbed PO obtained in step (2) 4 3- The resin was added to 20 mL of pH 5 containing 3.3 GBqSr-89 89 SrCl 2 In the solution, react at room temperature for 4 hours, make the cationic radionuclide in the solution react with the anion exchanged into the resin to form a precipitate, and then wash the precipitated resin with Sr-89 with distilled water until the pH value of the washing solution is 6, to obtain 89 Sr ...

Embodiment 2

[0060] At room temperature, put 1 g of OH-type strongly basic styrene-divinylbenzene anion exchange resin (201×7 resin) with a crosslinking degree of 7% and a diameter of 20 μm to 40 μm in a mass of 20 mL with a pH value of 11 The percentage concentration is 4% Na 2 WO 4 Soaked in the solution for 50min, the WO 4 2- Exchange to the inside of the anion resin; wash with water until the pH value of the cleaning solution is less than 8;

[0061] will be adsorbed with WO 4 2- The anion resin was added to 20mL, pH value of 5 containing 3.3GBq Sr-89 89 SrCl 2 In the solution, react at room temperature for 4 hours, make the cationic radionuclide in the solution react with the anion exchanged into the resin to form a precipitate, and then wash the precipitated resin with Sr-89 with distilled water until the pH value of the washing solution is 6, to obtain 89 Sr anion resin microspheres 2.

[0062] Soak the prepared Sr-89 anion resin microspheres 1 and 2 in normal saline and hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com