Processing method of low-temperature vacuum fried fragrant and crispy fish oil immersed can

A low-temperature vacuum frying and processing method technology, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of dark color of finished products, high nutritional loss, excessive dehydration, etc., achieve smooth surface, crisp taste, slow down oxidation and rancid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

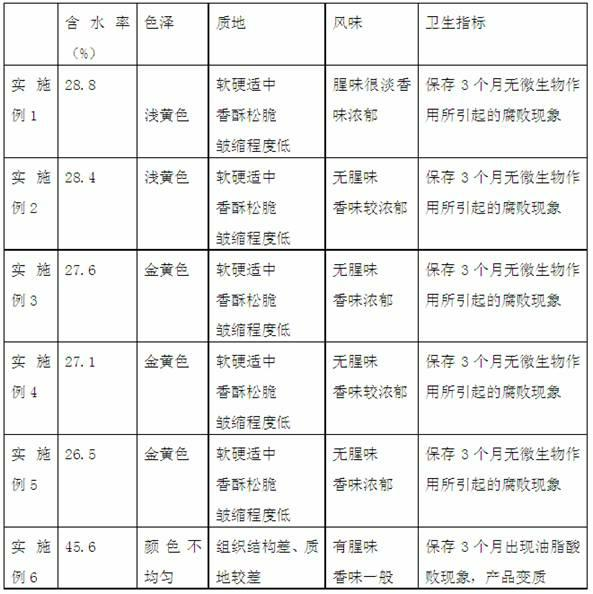

Examples

Embodiment 1

[0028] (1) Select and wash clove fish raw materials;

[0029] (2) Deodorization: Soak the clove fish in the deodorization solution for 1 hour, and then rinse with clear water for 15 minutes, which can effectively remove the fishy smell of the clove fish; the preparation of the deodorization solution: add 0.1ml of dilute hydrochloric acid and 0.4 mg table salt, stirred and shaken to mix;

[0030] (3) Low-temperature vacuum frying: Preheat the oil temperature to 110°C, put the raw materials into a low-temperature vacuum fryer (Shanghai Hongshen Vacuum Technology Development Co., Ltd.) to close the system, vacuumize, and the vacuum degree is stable at 0.03MPa. Start the oil circulation system, fill the frying chamber with hot oil and start frying with a ratio of oil to material of 1.5:1, the oil temperature is controlled at 110°C, and the frying time is 20 minutes;

[0031] (4) Seasoning: Pour the fried fish into the seasoning liquid while it is hot, mix the fried fish and seaso...

Embodiment 2

[0040] (1) Select raw materials of clove fish, wash and drain;

[0041] (2) Deodorization: Soak the clove fish in the deodorization solution for 1.5 h, then rinse with clear water for 15 minutes, which can effectively remove the fishy smell of the clove fish; the preparation of the deodorization solution: add 0.2 ml of dilute hydrochloric acid and 0.4 per 100 ml of water mg table salt, stirred and shaken to mix;

[0042] (3) Low-temperature vacuum frying: Preheat the oil temperature to 110°C, put the raw materials into the low-temperature vacuum fryer to close the system, vacuumize, the vacuum degree is stable at 0.04MPa, start the oil circulation system, and fill the frying chamber Put in the hot oil and start frying, the ratio of the amount of oil used to the material is 1.5:1, the oil temperature is controlled at 110°C, and the frying time is 20 minutes;

[0043] (4) Seasoning: Pour the fried fish into the seasoning liquid while it is hot, mix the fried fish and seasoning ...

Embodiment 3

[0048] (1) Select and wash clove fish raw materials;

[0049] (2) Deodorization: Soak the clove fish in the deodorization solution for 1 hour, then rinse with clear water for 20 minutes, which can effectively remove the fishy smell of the clove fish; the preparation of the deodorization solution: add 0.1ml of dilute hydrochloric acid and 0.5 mg table salt, stirred and shaken to mix;

[0050] (3) Low-temperature vacuum frying: Preheat the oil temperature to 120°C, put the raw materials into the low-temperature vacuum fryer to close the system, vacuumize, the vacuum degree is stable at 0.04MPa, start the oil circulation system, and fill the frying chamber Put in hot oil and start frying, the ratio of oil to material is 2:1, the oil temperature is controlled at 115°C, and the frying time is 20 minutes;

[0051] (4) Seasoning: Pour the fried fish into the seasoning liquid while it is hot, mix the fried fish and seasoning evenly, and season for 20 minutes. The ratio of seasoning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com