Method for covering mulching film on farmland

A technology of plastic film covering and plastic film, which is applied in the direction of plant protection cover, climate change adaptation, etc., can solve the problems of white pollution, inability to effectively recycle the farmland environment, easy aging and damage of plastic film, etc., achieve low cost, alleviate the process of aging and fragmentation, and relieve white Effects of Pollution Hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

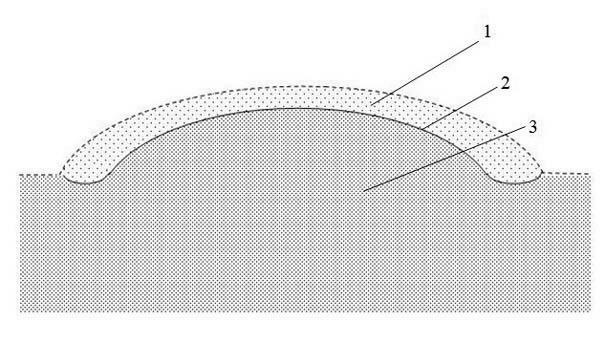

[0012] For seedling transplanting field, such as figure 1 As shown, on the basis of applying sufficient base fertilizer and fine soil preparation, remove the dry soil on the surface of the mulching operation area 3 to both sides of the operation area, and cover the mulching film 2 according to the conventional mulching method, and stretch and straighten it when laying the film , Seal tightly, and the ground temperature rises rapidly after mulching to promote transplanting and returning seedlings. After transplanting and returning seedlings, remove the foreign matter such as stubbles and stones from the surface layer of fine soil that was previously piled on both sides of the mulching film laying operation area, and cover them evenly on the mulching film 2 Above, the soil protection layer 1 is completely covered until the crops are harvested. The thickness of the protective layer composed of surface fine soil is 2cm. In combination with conventional plastic film laying or intert...

Embodiment 2

[0014] For the areas where the frost-free period is short and need to increase the accumulated temperature to seize the farming time, on the basis of conventional plastic film mulching cultivation and applying sufficient base fertilizer for fine soil preparation, remove the dry soil on the surface of the plastic film mulching operation area to both sides of the operation area, grab moisture and cover the plastic film according to the conventional plastic film mulching method, and lay The film should be tightened, straightened, and tightly sealed. After the film is laid, the ground temperature will rise rapidly to promote seed germination. After the seeds germinate and germinate, the surface fine soil temporarily piled on both sides of the film laying operation area will be temporarily piled up in combination with the field operation of digging out the seedlings and sealing the soil. Remove root stubble, stones and other foreign objects and cover them evenly on the plastic film, ...

Embodiment 3

[0016] Different from Embodiment 1 and Embodiment 2, the sun protection layer is covered on the mulch film during the whole period from the laying of the mulch film to the harvest of the crops. This method can better protect the mulch film.

[0017] In other embodiments of the present invention, different from the above-mentioned embodiments, the conventional method of laying the plastic film does not need to clean the surface soil in the laying of the plastic film. The difference from the above-mentioned embodiment is that the thickness of the protective layer formed by the fine soil on the surface can also be determined according to It needs to be adjusted, and it can be 1cm or less than 1cm. In other embodiments of the present invention, different from the above-mentioned embodiments, the protective layer can also be soft crop straw or soft weeds such as rice straw and wheat straw, or it can be For other shading materials such as sunshade nets, two or three kinds of shading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com