Laminar conditioned egg drying device

A dryer and body technology, applied in the direction of egg drying, drying gas arrangement, drying solid materials, etc., can solve the problems of reducing effect, not being able to apply, not being able to dry with roller rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

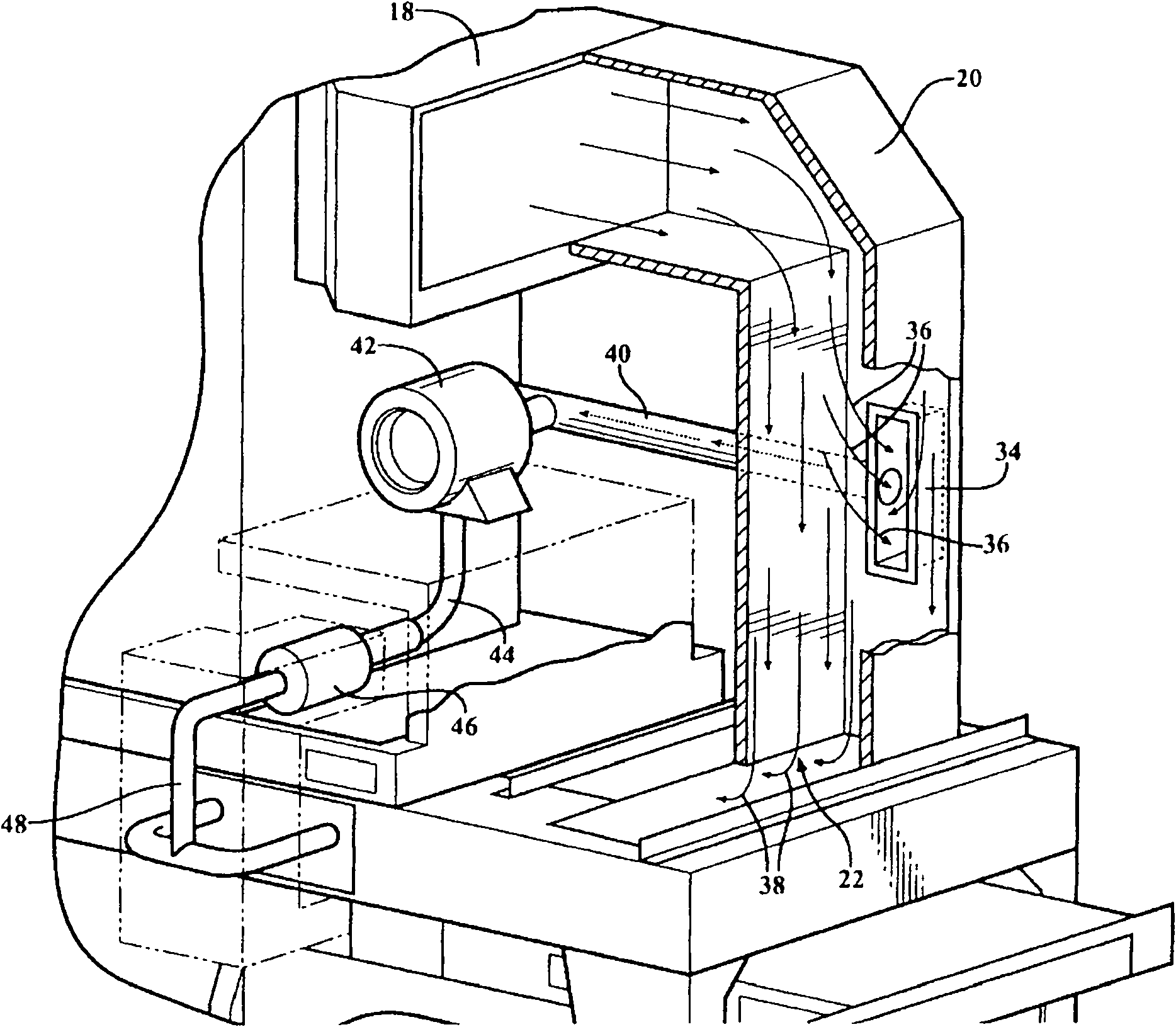

[0020] As noted above, the present invention teaches an improved egg drying apparatus for more quickly and efficiently drying pre-washed eggs, wherein a reduced humidity (drying) and typically heated air stream is passed and dried The path of travel of the egg conveyed by the defined channel or internal pipe associated with the container is generally parallel and reversed laminar state is introduced. Typically, an egg drying device is incorporated into an egg transfer / handling assembly, such as between an egg washer and subsequently positioned sorter and packer components, it being also understood that the dryer may be configured in any manner or configuration without any limitation. Used in egg transfer or handling units to dry washed eggs.

[0021] Now refer to the 2D perspective and 3D perspective respectively figure 1 with figure 2 , which generally show a dryer arrangement designated 10 incorporating a laminarly conditioned, dry gas flow according to the invention. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com