Determination method of rhodamine b content in plastic packaging materials

A technology of plastic packaging and detection methods, applied in the direction of material separation, material analysis, measuring devices, etc., to achieve the effects of accurate quantification, high detection accuracy, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The steps of the detection method of Rhodamine B content in this plastic packaging material are as follows.

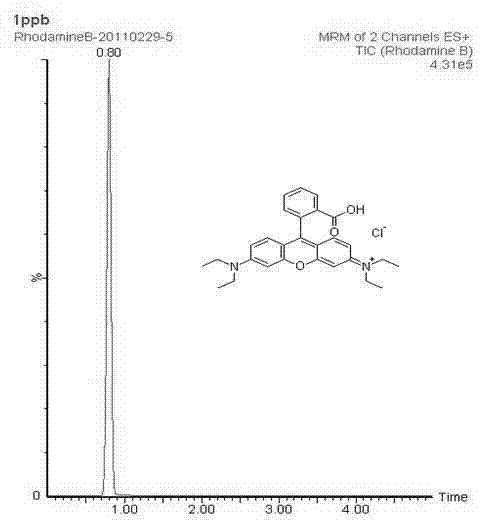

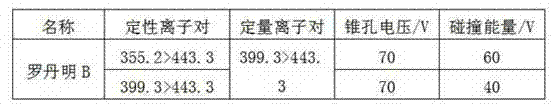

[0020] Break the plastic rope to a single particle ≤0.02g, accurately weigh 0.5g (accurate to 0.001g), add 50mL methanol, ultrasonically extract for 10min, ultrasonic frequency 40-80kHz, take out the supernatant, and continue to extract the bottom residue with 50mL methanol , sonicated for 10 minutes, and combined the two extracts; the extract was concentrated to nearly dryness with a rotary evaporator, blown dry with a nitrogen blower, and then fixed to 10 mL with methanol, and passed through a 0.22 μm filter membrane to obtain a sample solution; 1 μL of the sample solution was used in the United States Waters Acquity-TQD ultra-high performance liquid chromatography tandem mass spectrometry detection, the chromatographic column is a BEH reversed-phase C18 ultra-high-efficiency chromatographic column, the specification is 50mm*2.1mm, the particle si...

Embodiment 2

[0029] Embodiment 2: The steps of the detection method of rhodamine B content in this plastic packaging material are as follows.

[0030] Cut the plastic packaging bag to a single particle ≤ 0.02g, accurately weigh 0.2g (accurate to 0.001g), add 20mL of acetonitrile, vortex extract for 20min, vortex power 40-150W, take out the supernatant as the extract; extract Concentrate to near dryness with a liquid rotary evaporator, blow dry with a nitrogen blower, then dilute to 5 mL with acetonitrile, and pass through a 0.22 μm filter membrane to obtain a sample solution; 5 μL of the sample solution is detected by an American Waters Acquity-TQD ultra-high performance liquid chromatography tandem mass spectrometry , The chromatographic column is a BEH reversed-phase C18 ultra-high-efficiency chromatographic column with a specification of 50mm*2.1mm and a particle size of 1.7μm. The mobile phase is a methanol-formic acid water system, and the area external standard method is used for quan...

Embodiment 3

[0037] Embodiment 3: The steps of the detection method of rhodamine B content in this plastic packaging material are as follows.

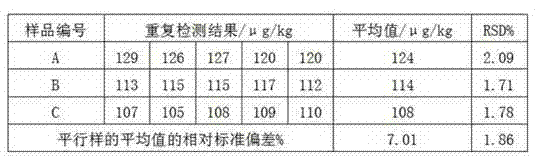

[0038]Crush the plastic bottle, accurately weigh 0.5g (accurate to 0.001g), add the rhodamine B standard sample into the powder sample in three gradients, add 50mL of methanol, extract by mechanical vibration for 30min at a frequency of 100-200rpm, take out The supernatant and the residue in the lower layer were extracted with 20 mL of methanol, and mechanically oscillated for 20 minutes; the supernatant was taken out again, and the residue in the lower layer was extracted with 10 mL of methanol, mechanically oscillated for 10 min, and the extracts were combined three times; Blow dry, then dilute to 5mL with methanol, pass through a 0.22μm filter membrane to obtain a sample solution; take 7μL sample solution and use American Waters Acquity-TQD ultra-high performance liquid chromatography tandem mass spectrometry detection, the chromatographic column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com