Air cylinder structure, internal combustion engine and compressor

A technology of internal combustion engine and cylinder, applied in the fields of cylinder structure, internal combustion engine and compressor, which can solve the problems of increasing the volume of vehicles or other machinery, increasing the length of cylinder structure, unfavorable maintenance and repair, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

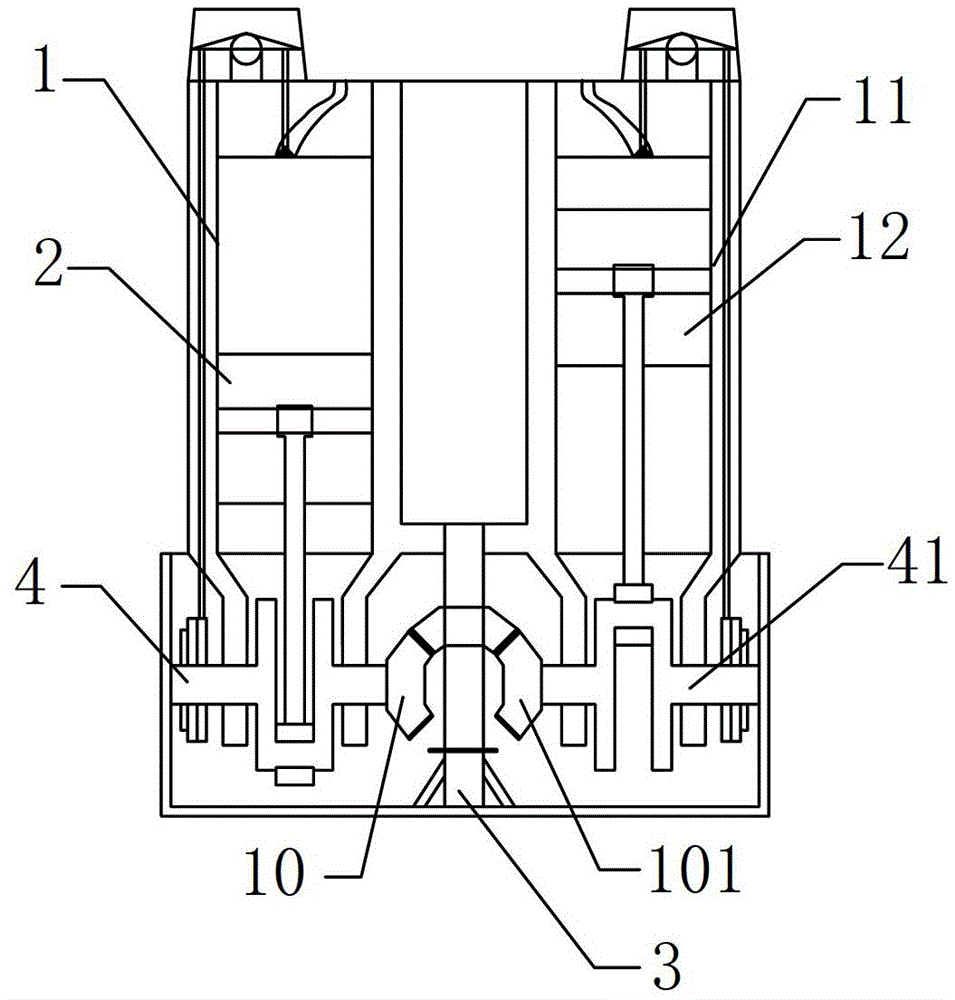

[0044] figure 2 As shown, the cylinder structure of the present invention includes a cylinder block, and 5 cylinders are distributed in the cylinder block, and each cylinder forms a ring together; a crankcase is arranged below the cylinder block, and in the crankcase Corresponding to each cylinder, an independent crankshaft is provided, and a main shaft 3 is arranged at the center of the crankcase, and each independent crankshaft is connected with the main shaft 3 through transmission.

[0045] The outer cylinder walls of two adjacent cylinders are tangent or partially overlapped.

[0046] The independent crankshafts are all meshed with the bevel gear fixedly connected to the main shaft 3 through the bevel gear arranged at one end thereof.

[0047] Wherein the cylinder 1 is provided with a piston 12; the independent crankshaft corresponding to the cylinder 1 is 4; the cylinder 11 is provided with a piston 12; and the independent crankshaft corresponding to the cylinder 11 is...

Embodiment 2

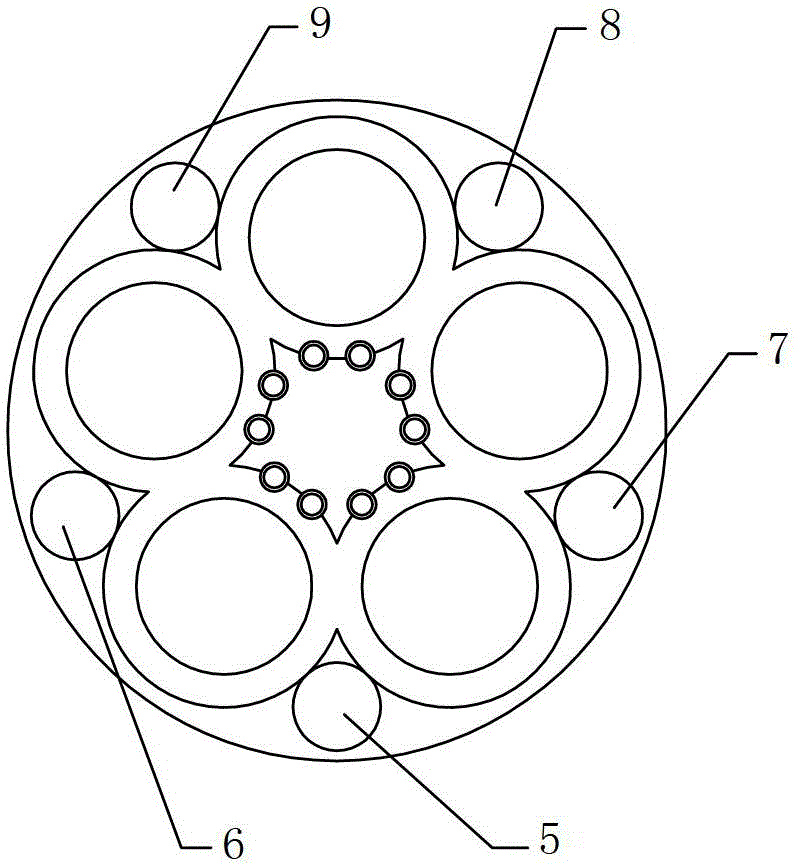

[0055] The cylinder structure of the present invention includes a cylinder block, and 7 cylinders are distributed in the cylinder body, and each cylinder forms a ring together; a crankcase is arranged below the cylinder block, and each cylinder corresponds to each cylinder in the described crankcase. Cylinder is provided with independent crankshaft, is provided with main shaft 3 at the center of crankcase, and each independent crankshaft is connected with main shaft 3 transmissions.

[0056] The outer cylinder walls of every two adjacent cylinders are tangent.

[0057] The internal combustion engine of the present invention includes the above-mentioned cylinder structure, and a starter 5, a generator 6, a fuel supply pump 7, an oil pump 8 and a water pump 9 are also provided in the grooves formed on the outer cylinder walls adjacent to the two cylinders.

[0058] The cylinder structure also includes a control unit for controlling the working order of the cylinders in the cylin...

Embodiment 3

[0062] The cylinder structure of the present invention includes a cylinder block, and 6 cylinders are distributed in the cylinder body, and each cylinder forms a ring together; a crankcase is arranged below the cylinder block, and each cylinder corresponds to each cylinder in the described crankcase. Cylinder is provided with independent crankshaft, is provided with main shaft 3 at the center of crankcase, and each independent crankshaft is connected with main shaft 3 transmissions.

[0063] The outer cylinder walls of two adjacent cylinders are tangent or partially overlapped.

[0064] The internal combustion engine of the present invention includes the above-mentioned cylinder structure, wherein the cylinder structure is also provided with a starter 5, a generator 6, a fuel supply pump 7, and an oil pump 8 in the grooves formed on the outer cylinder walls adjacent to the two cylinders. and water pump 9 .

[0065] The cylinder structure also includes a control unit for contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com