Engine exhaust gas energy recovery system

An energy recovery, engine cylinder technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of single cooling and heating purposes, low energy conversion efficiency of thermoelectric power generation, and low exhaust energy grade, etc., and achieve improvement. The overall oil consumption level, the effect of improving the performance under low working conditions, and increasing the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

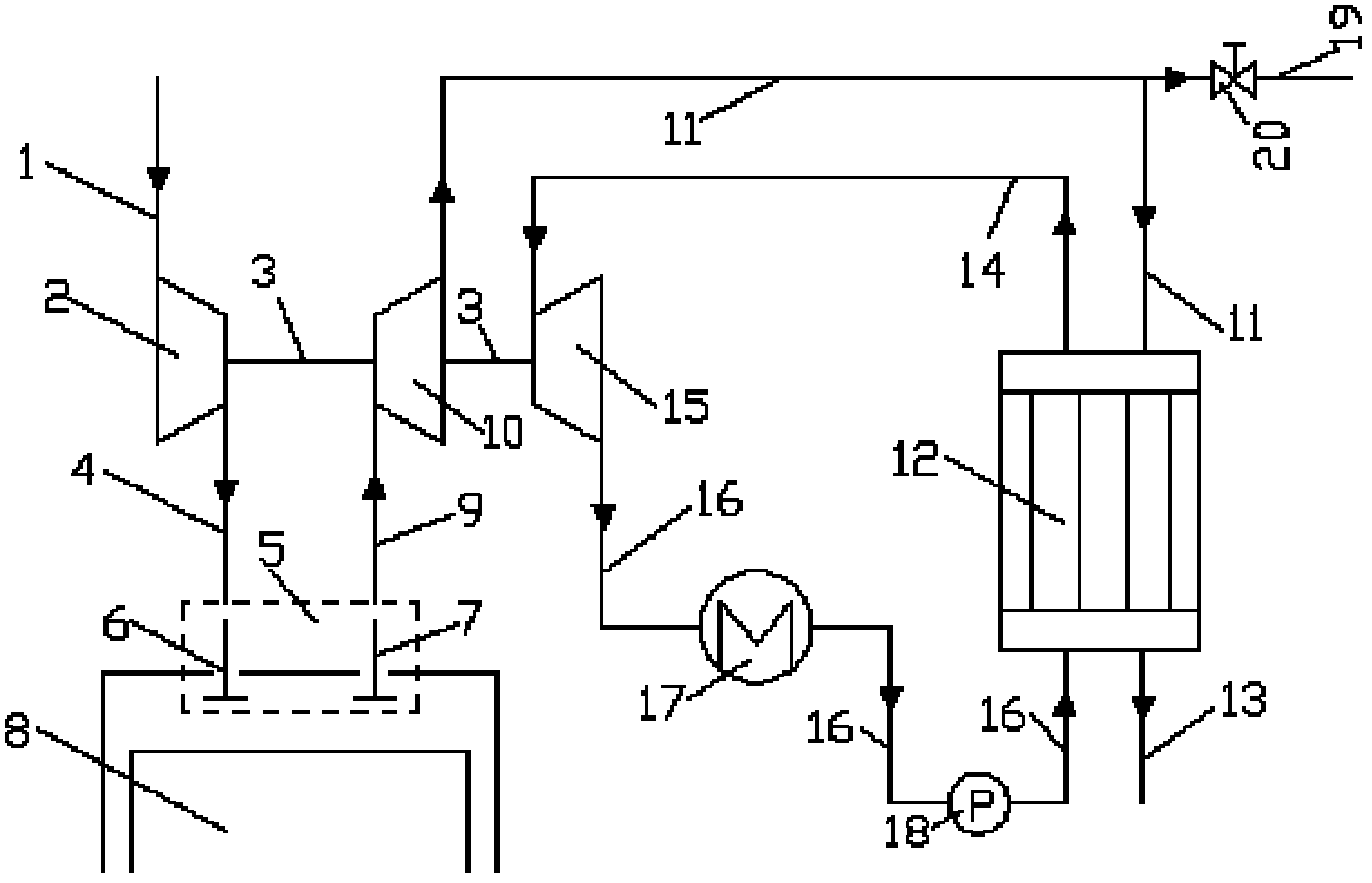

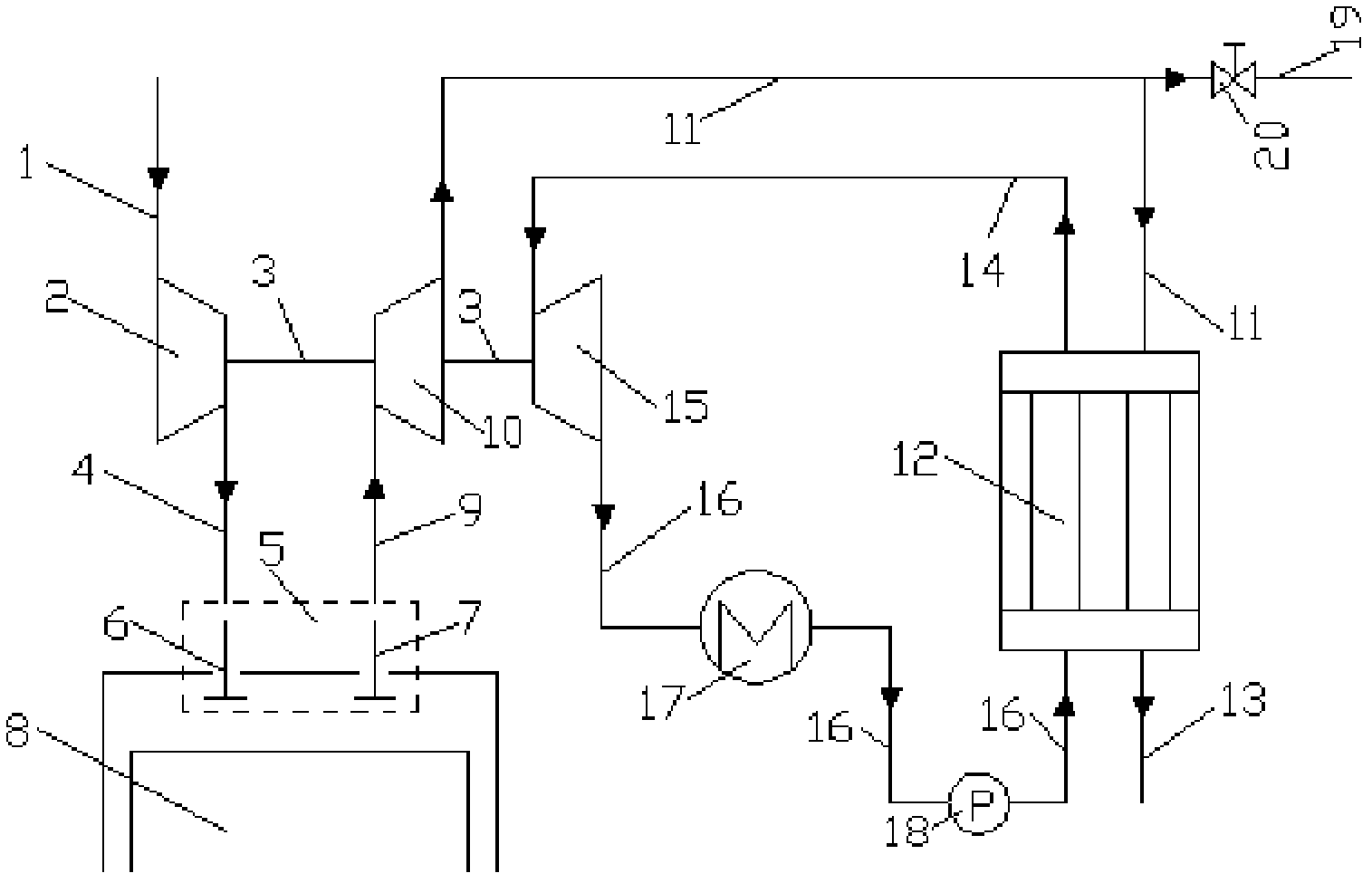

[0013] like figure 1 Shown, the present invention comprises: compressor intake pipe 1, compressor 2, connecting shaft 3, compressor outlet pipe 4, engine gas distribution mechanism 5, engine intake valve 6, engine exhaust valve 7, engine cylinder 8, the first A turbine inlet pipe 9, a first turbine 10, a first turbine outlet pipe 11, a heat exchanger 12, an exhaust pipe 13, a second turbine inlet pipe 14, a second turbine 15, a second turbine outlet pipe 16, and a condenser 17 , booster pump 18, bleed pipe 19 and bleed valve 20, the air inlet and outlet of compressor 2 are connected with the air outlet of compressor inlet pipe 1 and the air inlet of compressor outlet pipe 4 respectively, and the engine valve mechanism 5 is installed On the engine cylinder 8, the air outlet of the compressor air outlet pipe 4 and the air inlet of the first turbine intake pipe 9 are all connected with the engine cylinder 8, and the air inlet and outlet of the first turbine 10 are connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com