Heavy-duty car dual chamber non filtering net air filter

An air filter, heavy-duty vehicle technology, applied in the direction of fuel air filter, etc., can solve the problems of decreased output power, small intake flow of filtered air, shortened service life, etc., so as to reduce intake resistance and improve intake. The effect of air flow and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

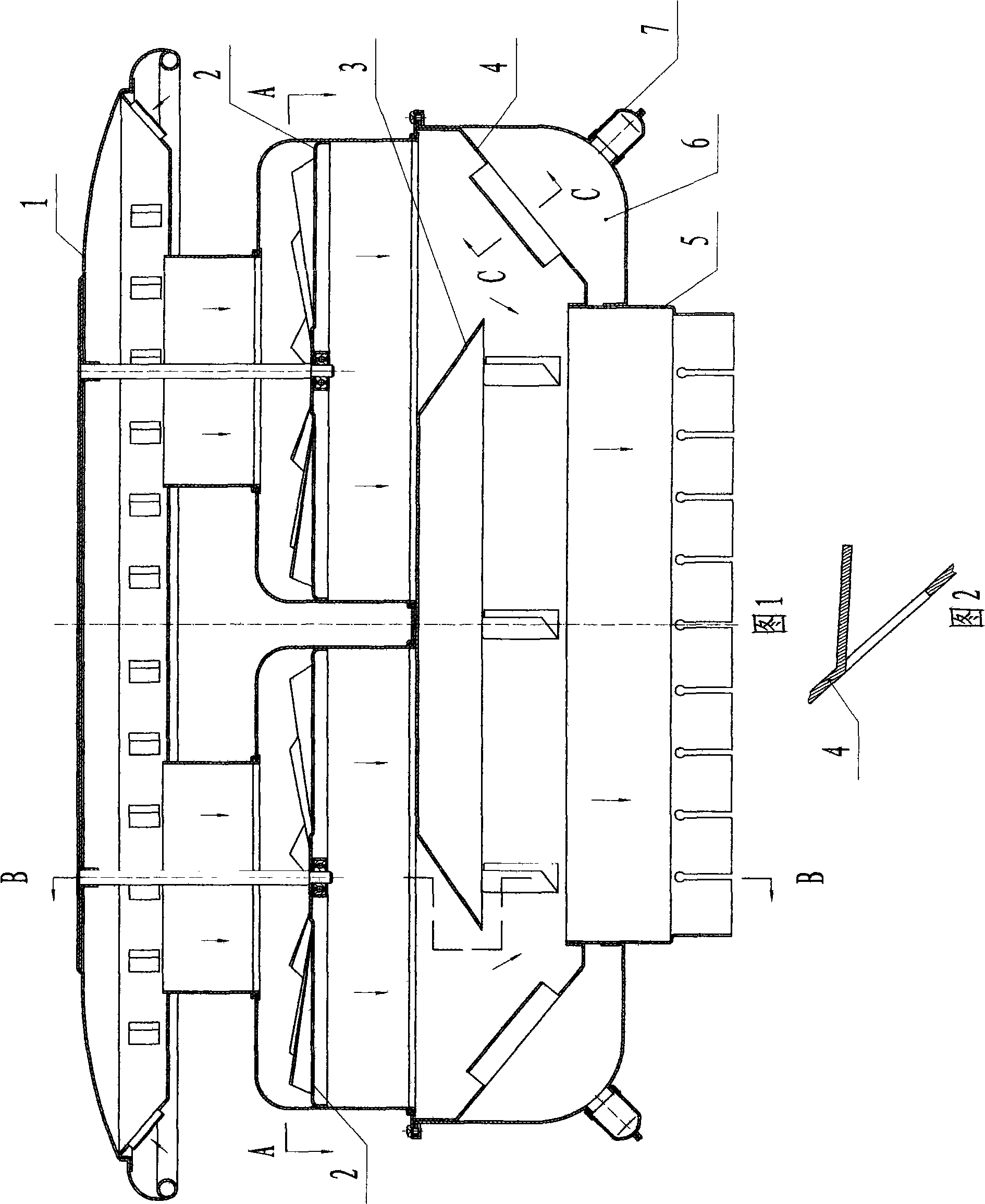

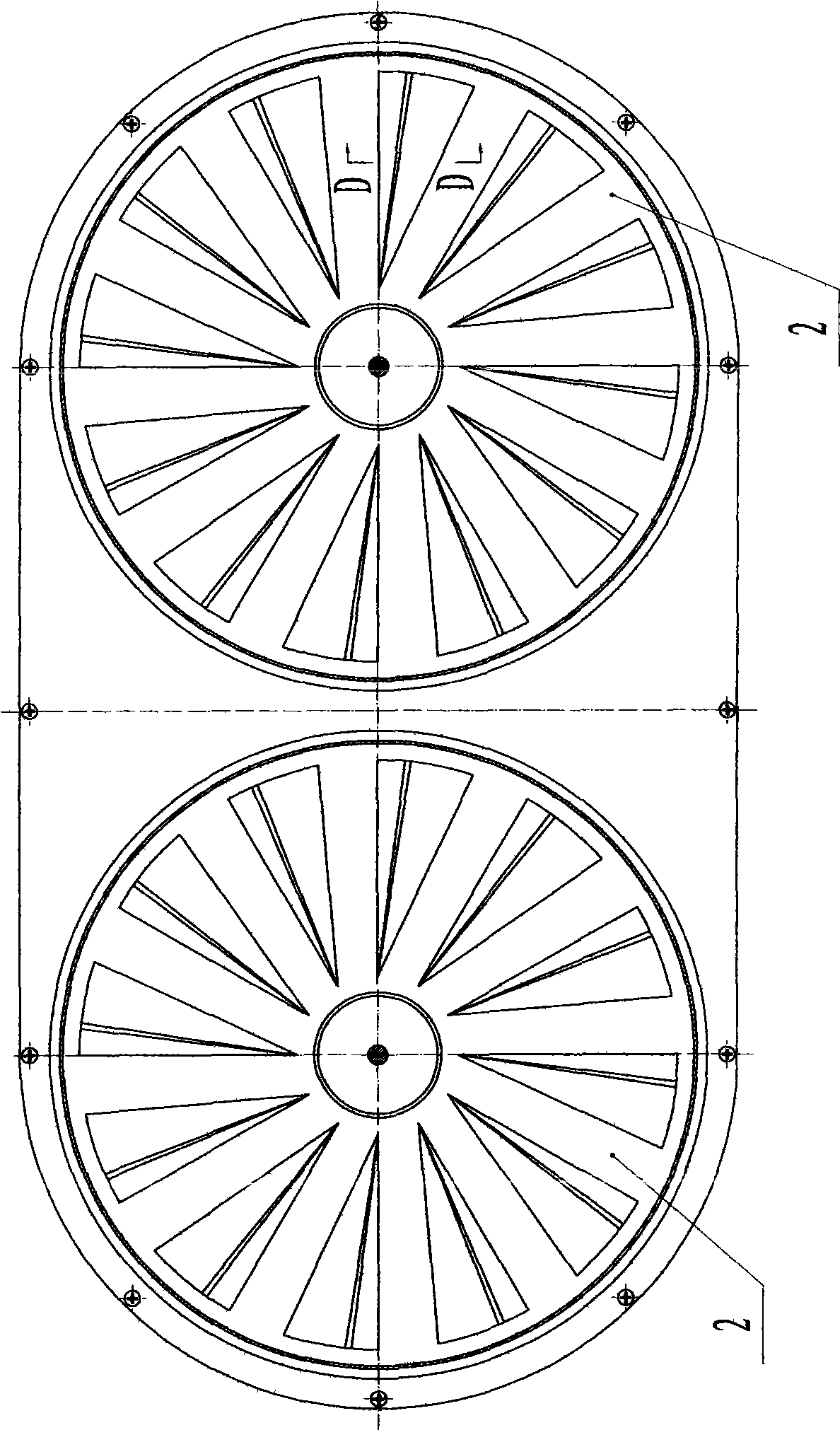

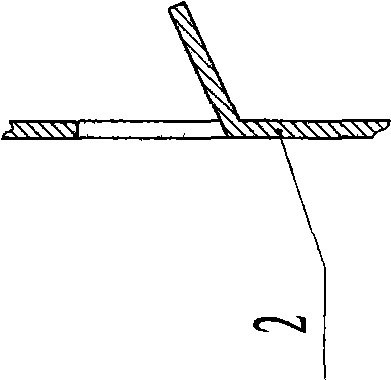

[0012] figure 1- Figure 6 shown. This heavy-duty automobile dual-chamber air filter without strainer, it is in the duplex inner chamber of waterproof air intake cover 1, is respectively provided with fixed shaft and is connected with the waterproof bearing that is fixedly connected on the wind impeller 2 and rotates (Fig. 1 , Figure 5 Shown); in the inner cavity of the waterproof air intake cover below the wind impeller 2, there is a cone-shaped air intake shunt cover 3 at intervals; the lower end of the inner cavity of the waterproof air intake cover 1 is connected with a dust collecting shell; On the outer circle of the air intake pipe 5 connected to the inner cavity of the dust collecting shell, the ring sleeve is connected with an inclined reverse dust suction cover 4 and connected with the dust collecting shell to form a dust collecting chamber 6 (Fig. 1, Figure 5 Shown); on the reverse suction cover 4 peripheral slopes, the direction of the air inlet is provided, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com