Corrosion inhibitor for calcium chloride antifreeze solution and preparation method thereof

A technology of antifreeze and corrosion inhibitor, which is applied in the field of corrosion inhibitor for calcium chloride antifreeze and its preparation, can solve the problems of expensive raw materials, complex synthesis process, and low corrosion inhibition efficiency, and achieve low cost, abundant sources, The effect of highly effective protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

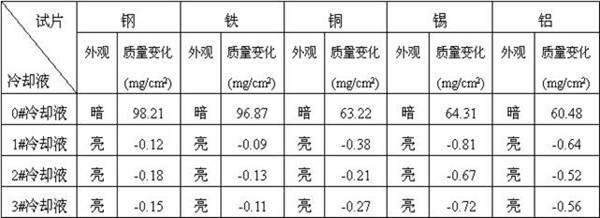

Image

Examples

Embodiment 1

[0019] The concrete steps of a kind of corrosion inhibitor preparation method for calcium chloride antifreeze are as follows:

[0020] ① Preparation of extract

[0021] Take about 250 grams of fresh white orchid leaves, wash them, dry them in the shade, cut them into pieces, add about 5 liters of water (about 20 times the weight of the white orchid leaves), and carry out ultrasonic-assisted leaching at 90°C for 1 hour, cool, stand still, and filter , collecting the extracted crude liquid and heating and concentrating to about 0.5 liters to obtain an extract (equivalent to 500 grams of white orchid leaf extract contained in each liter of the extraction liquid based on fresh white orchid leaf raw materials).

[0022] ② Preparation of corrosion inhibitor

[0023] The additive benzotriazole is added to the extract prepared in step ①, and the mixture is evenly mixed by stirring to obtain a corrosion inhibitor for calcium chloride antifreeze. Wherein, the addition amount of benzot...

Embodiment 2

[0025] The concrete steps of a kind of corrosion inhibitor preparation method for calcium chloride antifreeze are as follows:

[0026] ① Preparation of extract

[0027] Take about 400 grams of fresh white orchid leaves, wash them, dry them in the shade, cut them into pieces, add about 6 liters of water (about 15 times the weight of the white orchid leaves), and carry out ultrasonic-assisted leaching at 88°C for 80 minutes, cool, stand still, and filter , collecting the extracted crude liquid and heating and concentrating to about 1 liter to obtain an extract (equivalent to 400 grams of the white orchid leaf extract contained in each liter of the extract based on fresh white orchid leaf raw materials).

[0028] ② Preparation of corrosion inhibitor

[0029] The additive tolutriazole is added to the extract prepared in step ①, and stirred to mix evenly to obtain a corrosion inhibitor for calcium chloride antifreeze. Wherein, the addition of tolylbenzotriazole is about 0.0002% o...

Embodiment 3

[0031] The concrete steps of a kind of corrosion inhibitor preparation method for calcium chloride antifreeze are as follows:

[0032] ① Preparation of extract

[0033] Take fresh white orchid leaves weighing about 450 grams, wash them, dry them in the shade, cut them into pieces, add about 8 liters of water (about 18 times the weight of the white orchid leaves), and carry out ultrasonic-assisted leaching at 86°C for 1.5 hours, cool, stand still, and filter , collecting the extracted crude liquid and heating and concentrating to about 1 liter to obtain an extract (equivalent to 450 grams of the white orchid leaf extract contained in each liter of the extraction liquid based on fresh white orchid leaf raw materials).

[0034] ② Preparation of corrosion inhibitor

[0035] The additive tolutriazole is added to the extract prepared in step ①, and stirred to mix evenly to obtain a corrosion inhibitor for calcium chloride antifreeze. Wherein, the addition amount of tolyl benzotria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com