High elasticity PE modified material, and its application in rectification and circle-restoration of PE pipe fittings

A modified material, high elasticity technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of low surface hardness, low creep resistance, positioning deviation, etc., to achieve low cost, The effect of increasing Shore hardness and increasing elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

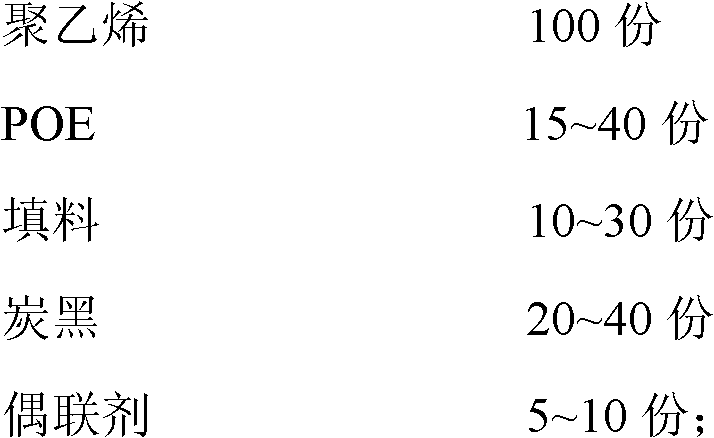

[0019] A kind of highly elastic PE modified material, it comprises following components and content (weight part):

[0020]

[0021] Preparation:

[0022] 1) Put the above raw materials into the high-speed mixer in turn, mix at 60°C for 40 minutes at high speed and release;

[0023] 2) Then send it into a twin-screw extruder, control the extrusion temperature of the extruder to be 220° C., and extrude and granulate;

[0024] 3) After radiation cross-linking treatment, product A is obtained.

Embodiment 2

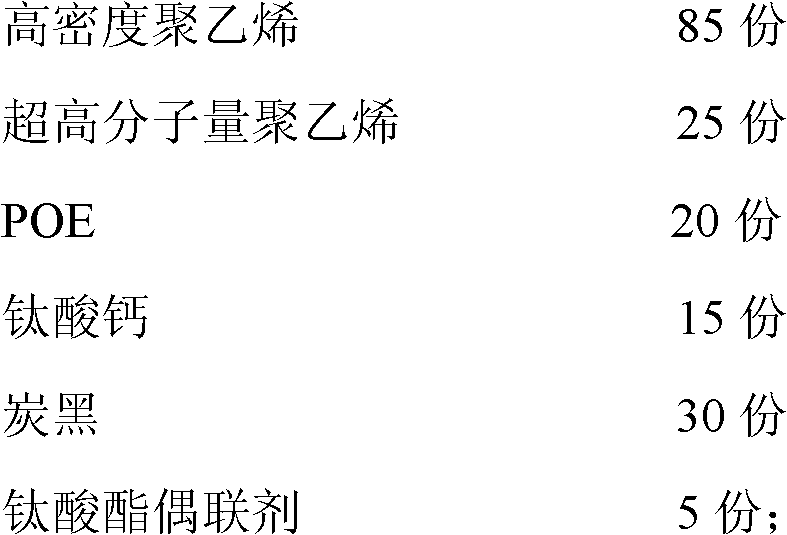

[0026] A kind of highly elastic PE modified material, it comprises following components and content (weight part):

[0027]

[0028]

[0029] The preparation method refers to Example 1 to obtain product B.

Embodiment 3

[0031] A kind of highly elastic PE modified material, it comprises following components and content (weight part):

[0032]

[0033] The preparation method refers to Example 1 to obtain product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com