Method for preparing hydrolytic polyacrylonitrile filtrate reducer by organic diamine cross-linking agent

A technology of fluid loss reducer and cross-linking agent, which is applied in the field of drilling fluid additives, can solve the problems of unsatisfactory overall effect, and achieve the effects of good product quality stability, improved product performance, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

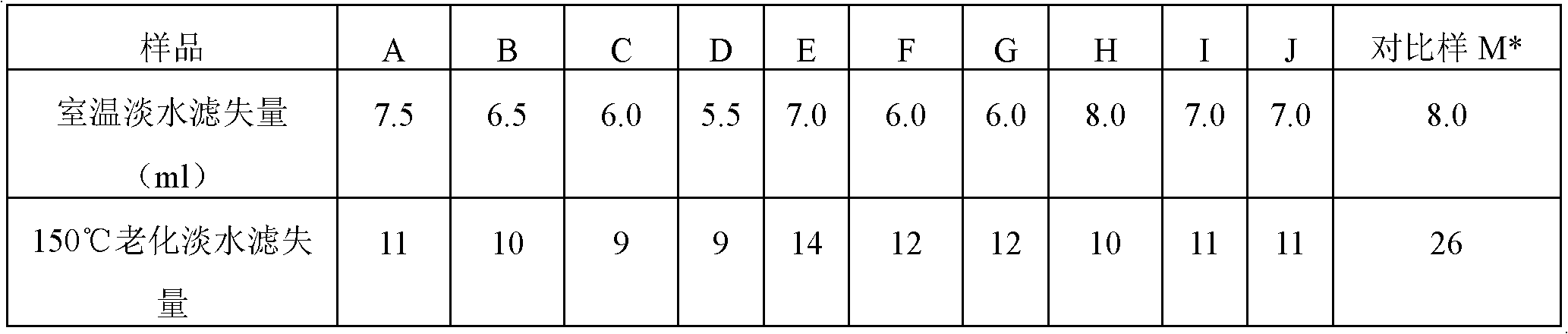

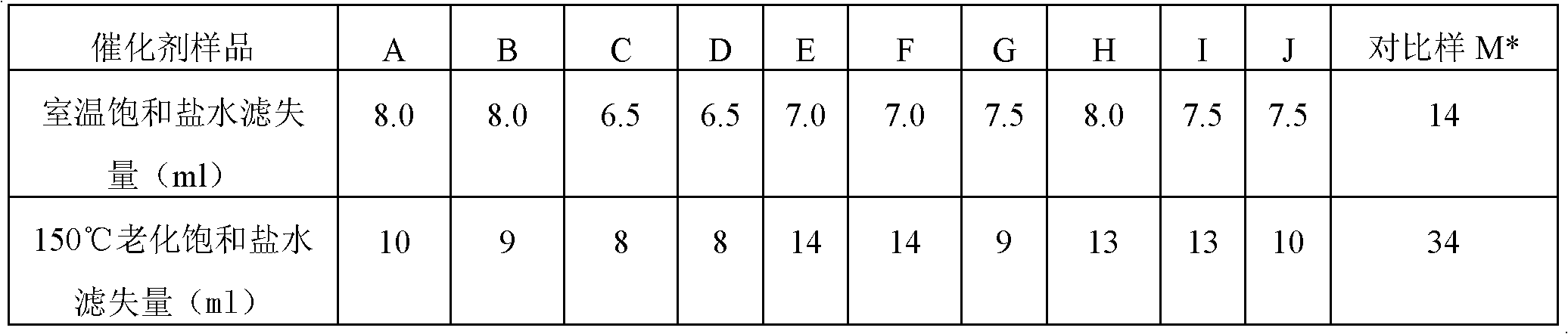

Embodiment 1

[0022] Wash with 800g waste acrylic fiber, after drying, join in the kneader of 5 liters. Then pour 100g of ethylenediamine into the above-mentioned kneader. 400g NaOH was configured into 1200g solution and poured into the above-mentioned kneader, and the heating was turned on to raise the temperature to 110°C. After the temperature of the kneader reached 110° C., kneading was started for 1 hour. Then the kneading was stopped, and the obtained jelly was dried at 110° C. for 10 hours, then crushed and passed through an 80-mesh sieve to obtain a powder, which was packaged. Denote it as product A.

Embodiment 2

[0024] Wash with 800g waste acrylic fiber, after drying, join in the kneader of 5 liters. Then pour 150g of ethylenediamine into the above kneader. 400g NaOH was configured into 1200g solution and poured into the above-mentioned kneader, and the heating was turned on to raise the temperature to 110°C. After the temperature of the kneader reached 110° C., kneading was started for 1 hour. Then the kneading was stopped, and the obtained jelly was dried at 110° C. for 10 hours, then crushed and passed through an 80-mesh sieve to obtain a powder, which was packaged. Denote it as product B.

Embodiment 3

[0026] Wash with 800g waste acrylic fiber, after drying, join in the kneader of 5 liters. Then pour 200g of ethylenediamine into the above-mentioned kneader. 400g NaOH was configured into 1200g solution and poured into the above-mentioned kneader, and the heating was turned on to raise the temperature to 110°C. After the temperature of the kneader reached 110° C., kneading was started for 1 hour. Then the kneading was stopped, and the obtained jelly was dried at 110° C. for 10 hours, then crushed and passed through an 80-mesh sieve to obtain a powder, which was packaged. Denote it as Product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com