Method for preparing hydrolyzed polyacrylonitrile filtrate reducer by cross-linking inorganic metal ions

A technology of fluid loss reducer and crosslinking agent, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of high cost, unfavorable industrial application, complicated formulation and preparation of fluid loss reducer, etc. Improved performance, environmental friendliness, good product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

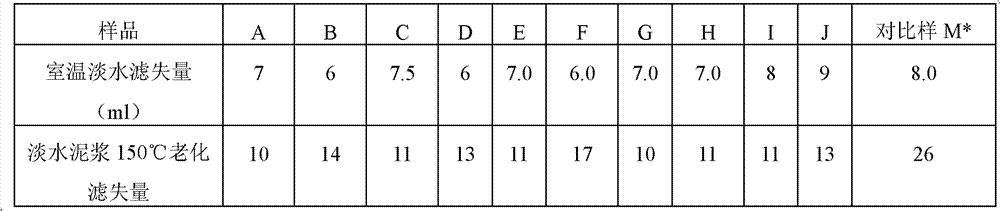

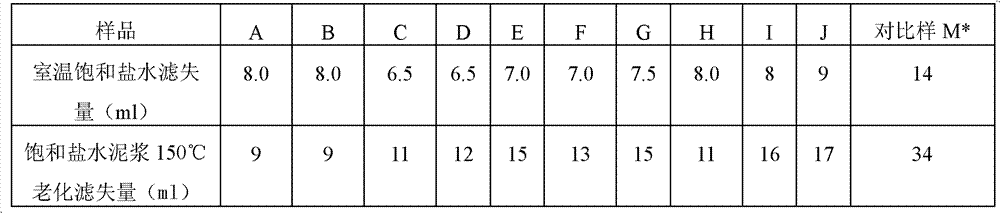

Examples

Embodiment 1

[0020] Wash with 800g of waste acrylic fiber, dry it, add it into a 5-liter kneader, configure 1200g solution of 400g NaOH and pour it into the above-mentioned kneader, heat up to 110°C, and start kneading. After kneading for 1 hour, the acrylic fiber was gradually hydrolyzed and turned brownish red, and then 30g of aluminum trichloride was poured into the above-mentioned kneader from the feeding port to continue kneading for 1 hour, and then the kneading was stopped, and the obtained jelly was dried at 110°C for 10 hours, and then Crush and pass through an 80-mesh sieve to obtain powder, which is packaged. Denote it as product A.

Embodiment 2

[0022] Wash with 800g of waste acrylic fiber, dry it, add it into a 5-liter kneader, configure 1200g solution of 400g NaOH and pour it into the above-mentioned kneader, heat up to 110°C, and start kneading. After kneading for 1 hour, the acrylic fiber was gradually hydrolyzed and turned brownish red, and then 50g of aluminum trichloride was poured into the above-mentioned kneader from the feeding port to continue kneading for 1 hour, and then the kneading was stopped, and the obtained jelly was dried at 110°C for 10 hours, and then Crush and pass through an 80-mesh sieve to obtain powder, which is packaged. Denote it as product B.

Embodiment 3

[0024] Wash with 800g of waste acrylic fiber, dry it, add it into a 5-liter kneader, configure 1200g solution of 400g NaOH and pour it into the above-mentioned kneader, heat up to 110°C, and start kneading. After kneading for 1 hour, the acrylic fiber is gradually hydrolyzed and turns brownish red, and then 80g of aluminum trichloride is poured into the above-mentioned kneader from the feeding port to continue kneading for 1 hour, then stop kneading, and the obtained jelly is dried at 110°C for 10 hours, and then Crush and pass through an 80-mesh sieve to obtain powder, which is packaged. Denote it as Product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com