Method for recovering 1,4-butanediol from waste liquor generated in production of 1,4-butanediol through Reppe method

A technology of butanediol and Rapper method, which is applied in the field of organic waste liquid recycling, can solve the problems of unsuitable treatment of small batches of waste liquid recycling and utilization, high equipment investment and operating costs, and long process, so as to facilitate popularization and application , Conducive to environmental protection and low recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] To the waste liquid (raw material) of 1,4-butanediol produced by the Rapper method, add the additive sodium carbonate according to the mass ratio of the additive to the raw material as 3:600, stir and mix evenly, and put the mixture into the still of the batch rectification tower , the batch distillation is operated under the following conditions:

[0023] (1) When the temperature of the tower bottom is 66-105°C, the temperature of the tower top is 47-100°C, the normal pressure, and the reflux ratio are 0.1-0.14, the light components mainly composed of water are extracted from the top of the tower, which contains a small amount of Tetrahydrofuran, methanol;

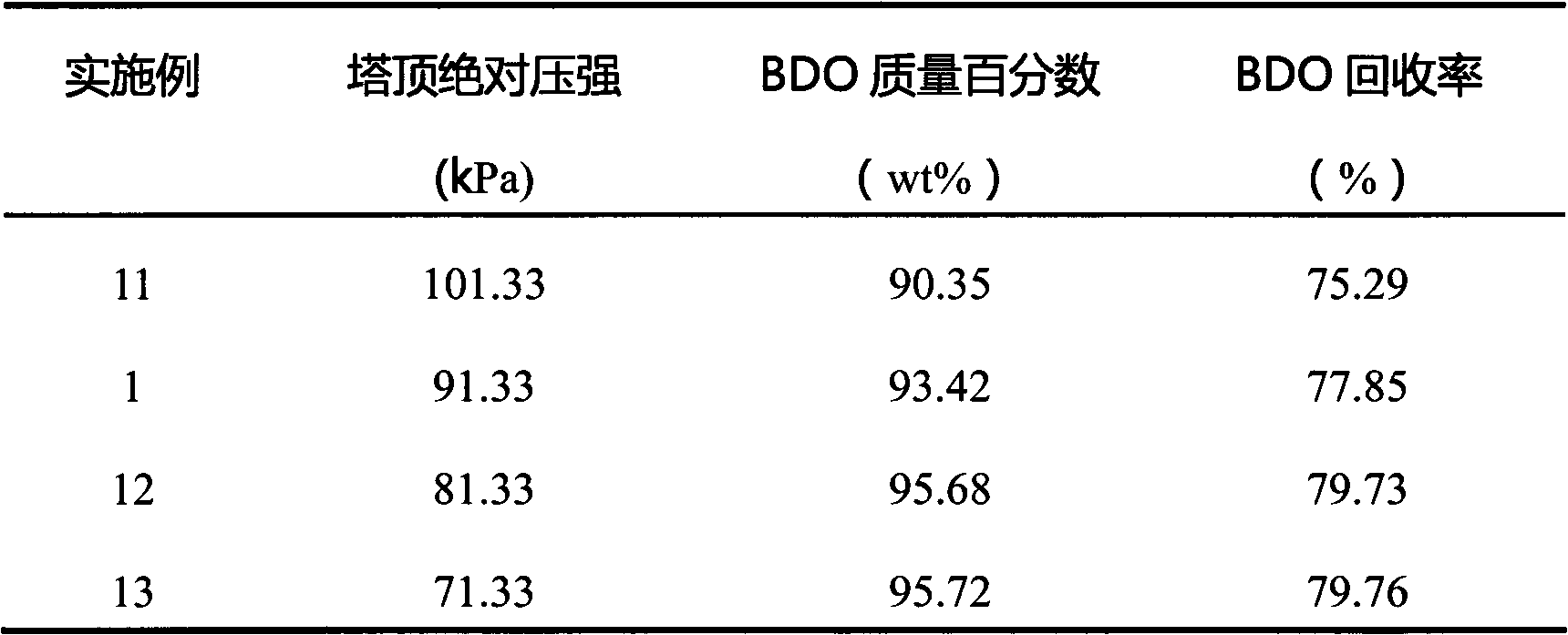

[0024] (2) When the temperature at the bottom of the tower is 105-200°C, the temperature at the top of the tower is 100-185°C, the absolute pressure at the top of the tower is 91.33kPa, and the reflux ratio is 0.2-0.35, extract the dihydric fusel alcohol from the top of the tower;

[0025] (3) When the temperature...

Embodiment 2~4

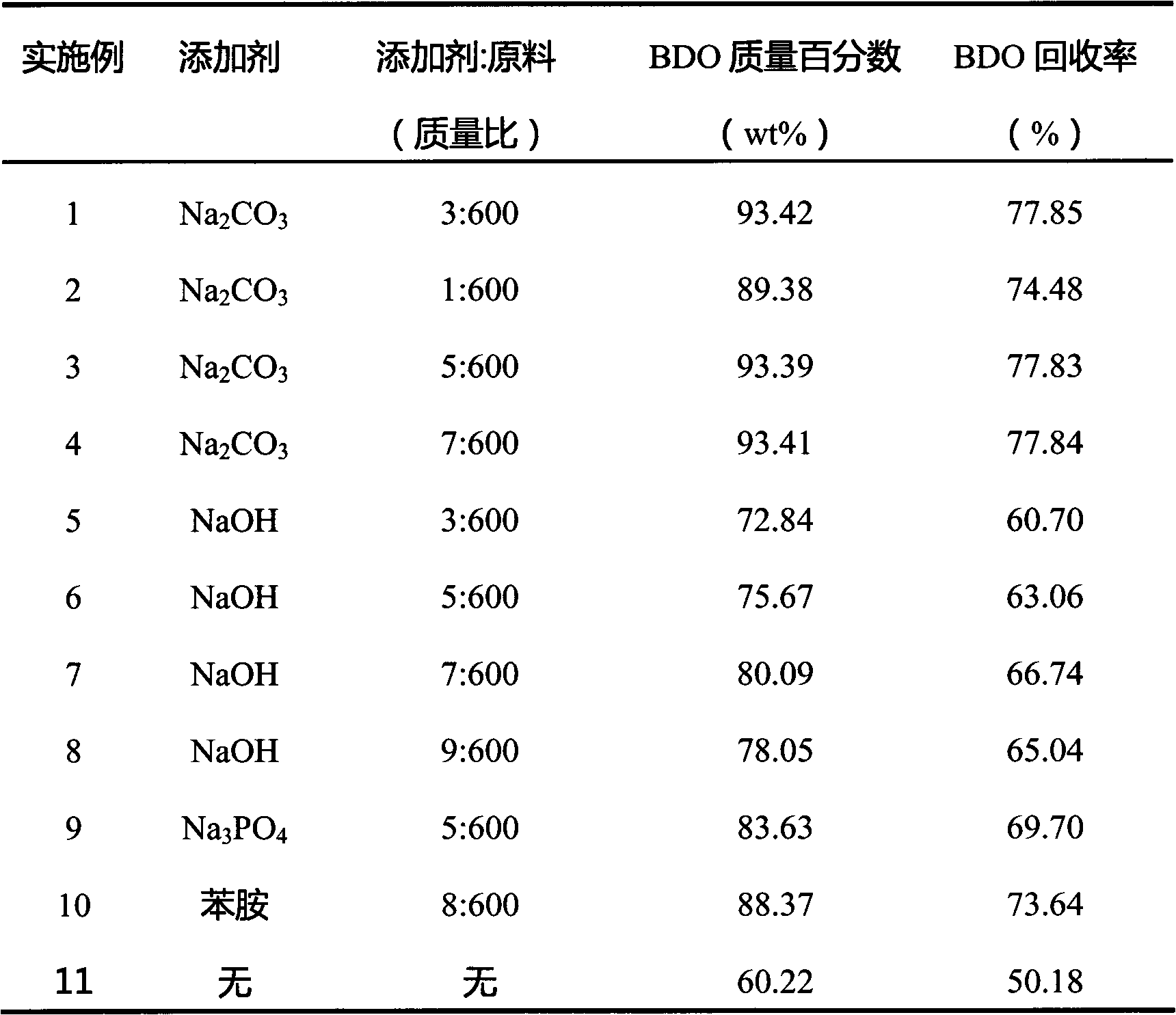

[0028] Operating conditions are identical with embodiment 1, and difference is that sodium carbonate and raw material mass ratio are respectively 1: 600, 5: 600, 7: 600, respectively extract 1, the mass percent of 4-butanediol product and reclaim Efficiency is also not the same, and the mass percent of the 1,4-butanediol product that embodiment 2, embodiment 3, embodiment 4 are extracted is respectively 89.38%, 93.39%, 93.41%, and the rate of recovery is respectively 74.48%, 77.83% %, 77.84%.

Embodiment 5~8

[0030] Operating conditions are identical with embodiment 1, and difference is that additive is sodium hydroxide, and the mass ratio of sodium hydroxide and raw material is respectively 3: 600, 5: 600, 7: 600, 9: 600, respectively extracts 1 , the mass percent of 4-butanediol product and the rate of recovery are also not the same, and the mass percent of the 1,4-butanediol product of embodiment 5, embodiment 6, embodiment 7, embodiment 8 mining is respectively 72.84% , 75.67%, 80.09%, 78.05%, the recoveries were 60.70%, 63.06%, 66.74%, 65.04%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com