Load-controllable multichannel liquid fuel gasification burner

A liquid fuel, controllable technology, applied in the direction of inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve the problems of poor atomization performance, difficult load control, poor burner cooling effect, etc., to achieve improved fog Excellent atomization performance, convenient production and maintenance, and sufficient atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

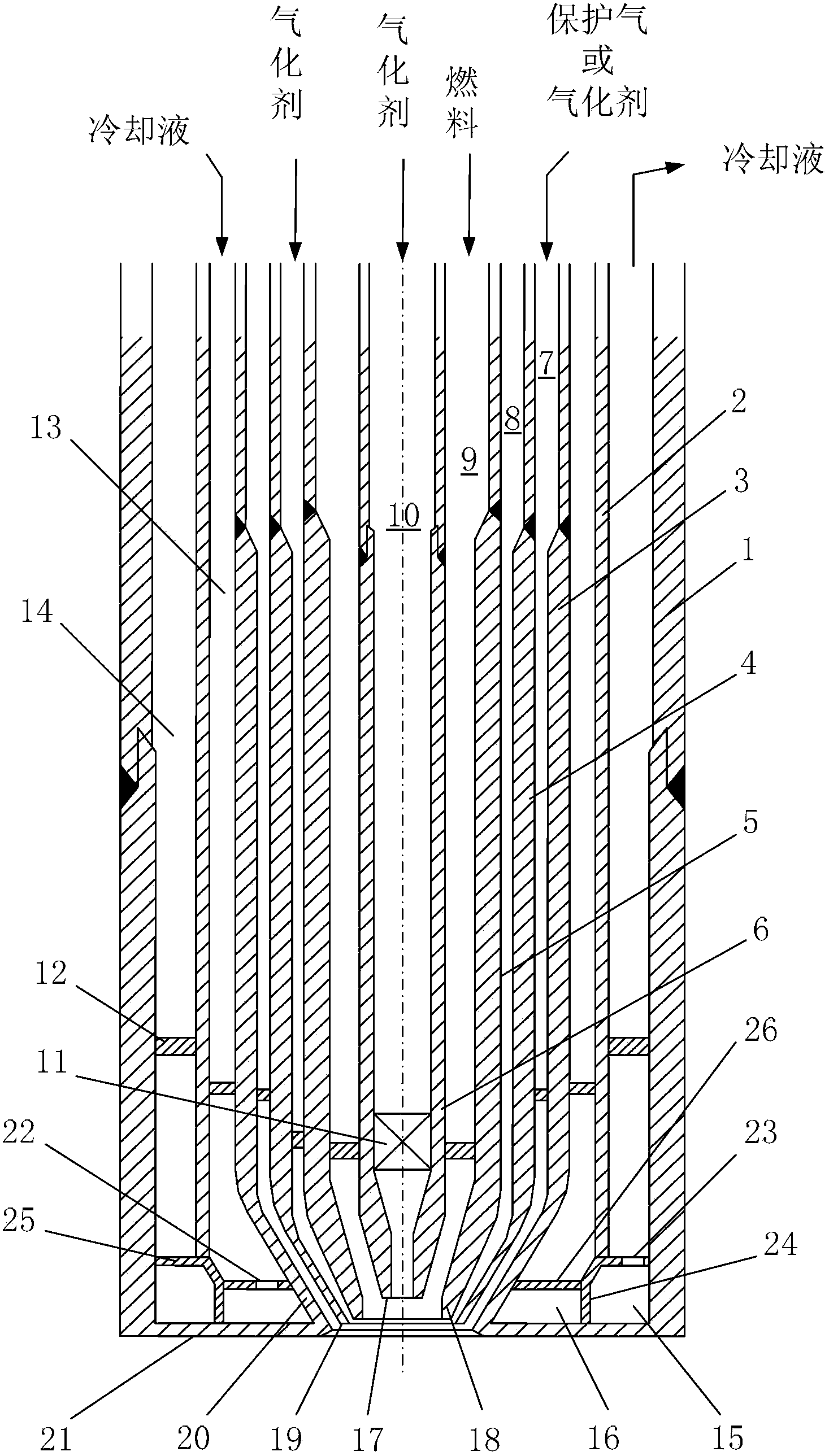

[0044] Figure 1~3 It is a schematic diagram of the peripheral structure and internal structure of the load controllable multi-channel liquid fuel gasification burner of the present invention. The burner includes a protective purge gas inlet 29, a central oxidant inlet 30, a fuel inlet 31, an outer ring channel oxidant inlet 32, an outer ring oxidant or protective gas inlet 33, a coolant inlet 34, a coolant outlet 35, and a connection method Lan 36, the coaxial burner center nozzle 6, the first burner outer ring nozzle 5, the second burner outer ring nozzle 4, the third burner outer ring nozzle 3 and the burner center nozzle 17, the second A burner outer ring nozzle 18, a second burner outer ring nozzle 19, a third burner outer ring nozzle 20, a cyclone 11 and a burner cooling system.

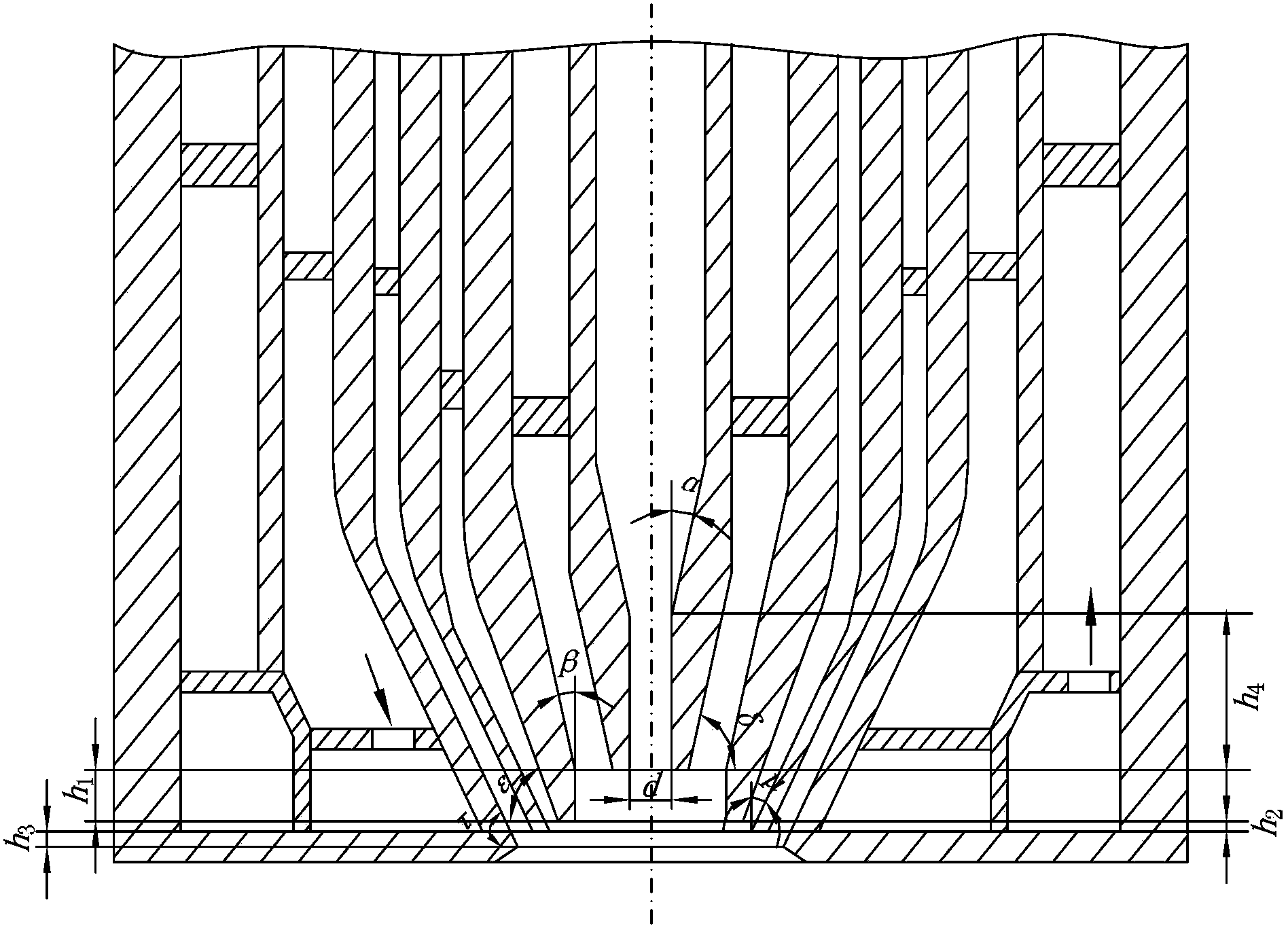

[0045] Said burner center nozzle 17, first burner outer ring nozzle 18, second burner outer ring nozzle 19 and third burner outer ring nozzle 20 are respectively a truncated conical tube. The...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that if the burner is installed in a single-nozzle overhead coal-water slurry gasifier, when the fuel is oil coke slurry with a concentration of 65%wt, the gas will be burned with 98% pure oxygen It is the gasification agent, and the gasification result is the effective gas components CO and H in the syngas 2 The sum of the volume percentage of the burner reaches 86%, the residual carbon of the ash residue is 4%, and the continuous service life of the burner can reach 5 months, which fully meets the requirements of the gasification of oil coke slurry.

[0060] Said burner structure parameters are as follows:

[0061] β is 15°, ε is 60°; β is 20°, ε is 45°; μ is 30°; τ is 60°. The nozzle diameter d of the nozzle 17 in the center of the burner and the height h of the straight section of the nozzle 4 The ratio of h 4 :d=3. The distance h between the nozzle end face of the burner center nozzle 17 and the nozzle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com