Pressure-equalizing type diamond synthesis device and diamond synthesis method based on device

A synthesis device and synthesis method technology, applied in the application of ultra-high pressure process, etc., can solve the problems of unbalanced pressure trend, unbalanced diamond particle size, shape, hardness characteristics, and affecting diamond synthesis efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Here, it should be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same structure and function, and redundant descriptions on components that are substantially the same are omitted in order to make the description more concise.

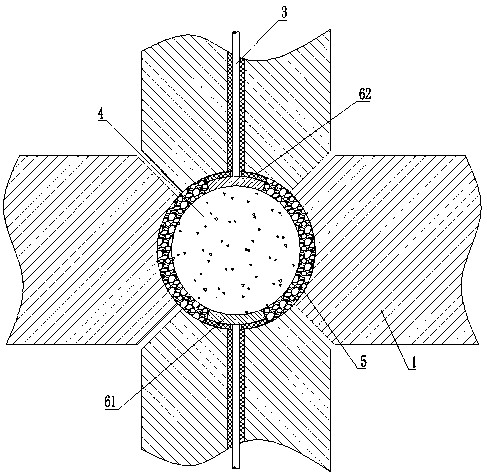

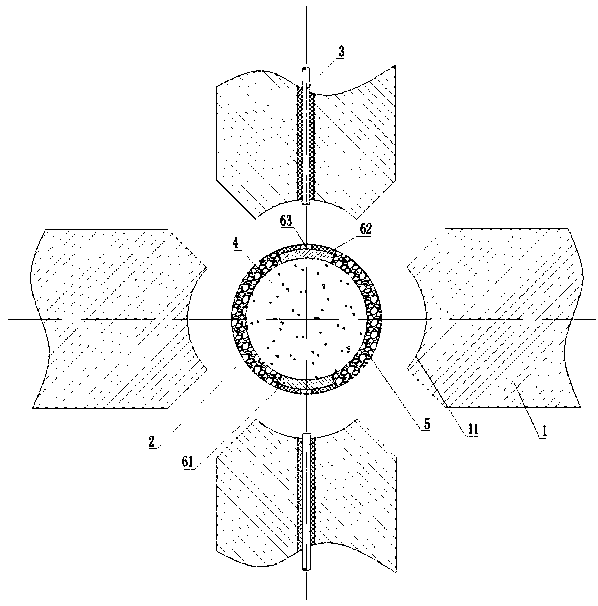

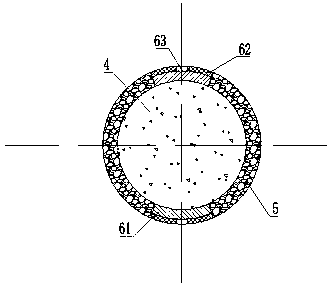

[0031] Such as figure 1 and figure 2 As shown, the equal-pressure diamond synthesis device includes a six-sided top, including six top hammers 1, figure 1 and figure 2 Only the top, bottom and left and right four top hammers 1 sections are shown in the figure, and the two top hammers 1 in the vertical section direction are not shown in the figure; the top hammer 1 of the six-sided top has a concave arc top pressure surface 11, The six concave arc-shaped pressing surfaces 11 have the same shape, and the concave arc-shaped pressing surfaces 11 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com