Amorphous alloy transformer with three-dimensional antitorque clamp and iron core parallel independent distribution structure

An amorphous alloy and transformer technology, applied in the field of amorphous alloy transformers, can solve problems such as affecting product loss characteristics, discrete dimensional accuracy, and deteriorating energy-saving performance, so as to improve the distribution of iron core force, improve iron core force state, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

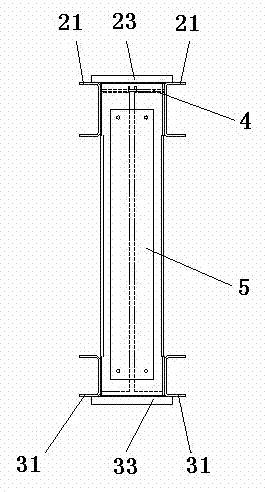

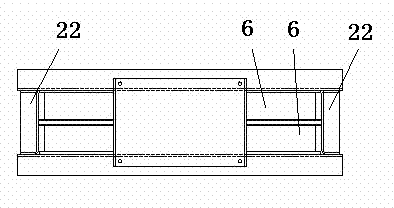

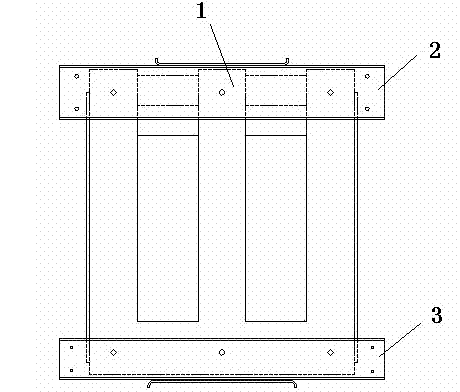

[0036] In the figure, the amorphous alloy transformer with three-dimensional torsion-resistant clamping and parallel independent distribution of iron cores includes: two pull plates (the first pull plate and the second pull plate) and the iron core sheet group, which is characterized in that it also includes an upper The frame-shaped clamping piece includes two upper clamping pieces placed in parallel with a certain distance apart, an upper end clamping piece connected with the ends of the two upper clamping pieces, and a top clamping plate connecting the tops of the two upper clamping pieces.

[0037] The lower frame-shaped clamp includes two lower clamps placed in parallel with a certain distance apart, a lower clamp connected to the ends of the two lower clamps, and a bottom clamp connected to the tops of the two lower clamps.

[0038] The distance between the two upper clips is the same as the distance between the two lower clips.

[0039] The top of the first pull plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com